Automatic material arranging device

A technology for sorting devices and materials, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of work intensity, high efficiency and cost, and large limitations, and achieve the effect of improving work efficiency and simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

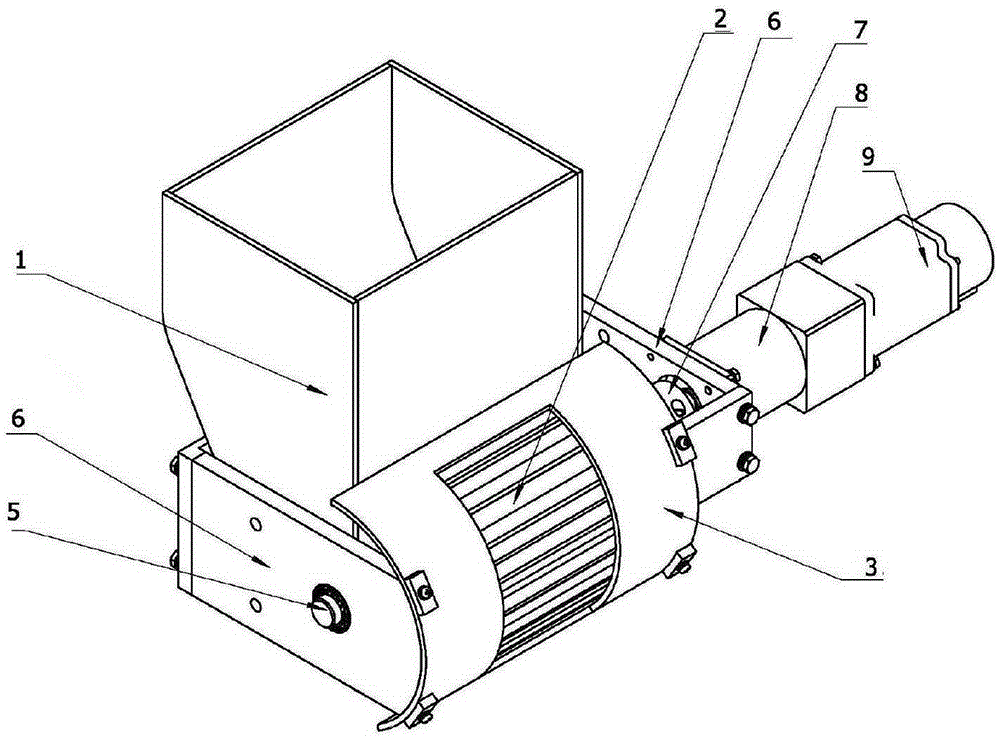

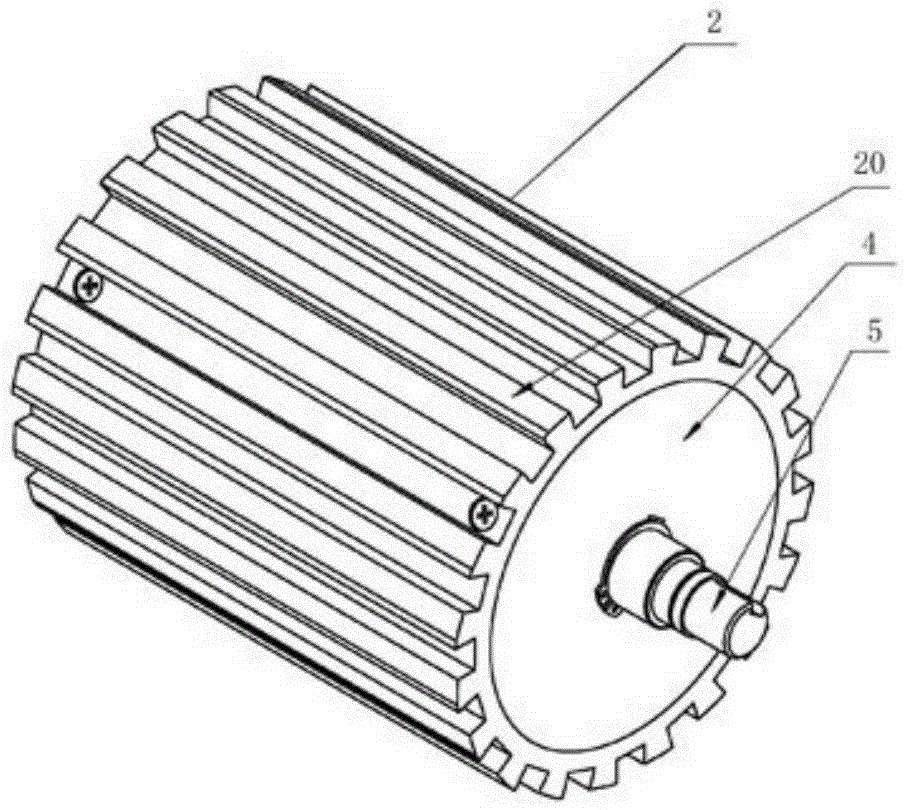

[0025] like figure 1 , figure 2 As shown, an automatic material sorting device includes a bin 1, a driving part and a sorting part. The bin 1 is connected to the sorting part, and the driving part is connected to the sorting part for driving the sorting part to move. The sorting part includes a drum 2 and a protective plate 3 corresponding to the drum. The protective plate 3 is in the shape of an arc. The protective plate is fixed on the outer periphery of the drum 2 and forms a channel for materials to pass between the drum 2 . Grooves 20 are arranged on the surface of the drum 2, and the size of the grooves 20 matches the material. The grooves 20 are evenly distributed on the surface of the drum 2, and the arc of the protective plate 3 is 150°. The drum 2 is installed on the support plate 6 through the central rotating shaft 5, and the two ends of the drum 2 are respectively fixed with end caps 4, and the end caps 4 are connected with the central rotating shaft 5 through ...

Embodiment 2

[0029] like figure 1 , figure 2 As shown, an automatic material sorting device is mainly used for sorting tubular objects or columns, including a bin 1, a driving part and a sorting part, the bin 1 is connected to the sorting part, and the driving part is connected to the sorting part , used to drive the finishing movement. The sorting part includes a drum 2 and a protective plate 3 corresponding to the drum. The protective plate 3 is in the shape of an arc. The protective plate is fixed on the outer periphery of the drum 2 and forms a channel for materials to pass between the drum 2 . Grooves 20 are arranged on the surface of the drum 2, and the size of the grooves 20 matches the material. The grooves 20 are evenly distributed on the surface of the drum, and the arc of the protective plate 3 is 180°. The drum 2 is installed on the support plate 6 through the central rotating shaft 5, and the two ends of the drum 2 are respectively fixed with end caps 4, and the end caps 4...

Embodiment 3

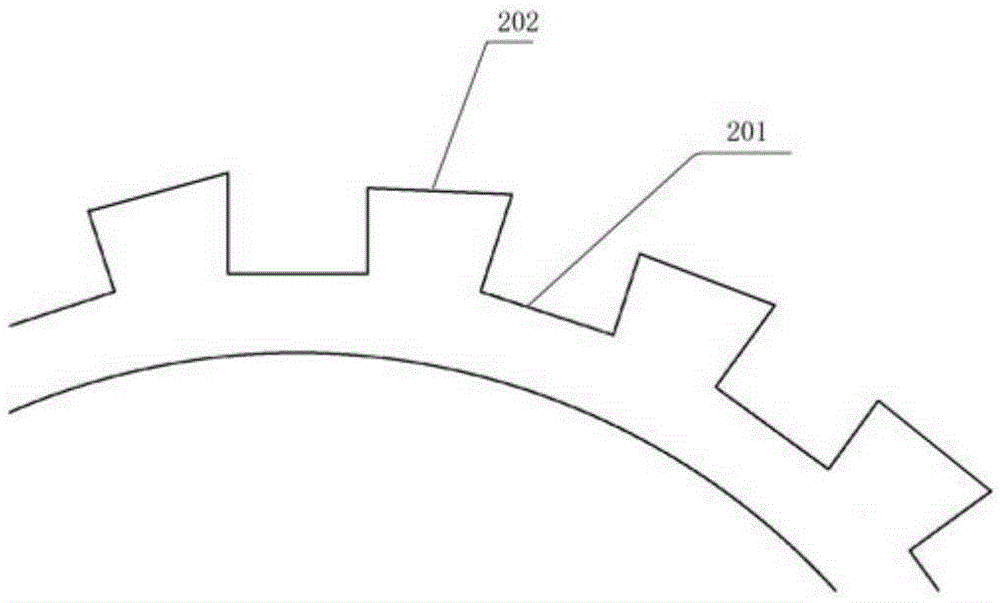

[0033] like figure 1 , figure 2 , Figure 4 As shown, an automatic material sorting device is mainly used for sorting tubular objects or columns. The difference from Embodiment 2 is that the groove 20 includes a groove bottom 201 and a groove top 202, and the groove top 20 includes a slope portion 202a and a groove top 202. The arc portion 202b, the inclined portion 202a and the arc portion 202b are parallel to the direction of the central axis of the drum 2, the inclined portion 202a and the arc portion 202b are connected, and the area of the inclined portion 202a accounts for the total area of the groove top 202 4 / 5 of the. This design can make the transfer and transition of the material more peaceful, so that the groove 20 does not squeeze the material, the success rate of carding the material is high, the failure rate is greatly reduced, the operating rate is greatly improved, and the operating rate is close to 100%, thereby improving work efficiency.

[0034] Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com