Millimeter paper cutting device

A technology for entering the standard and fixing the plate, which is applied in the directions of transportation and packaging, sending objects, thin material processing, etc., can solve the problems of high manufacturing cost, complex structure of the decorative strip feeding device, and large space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

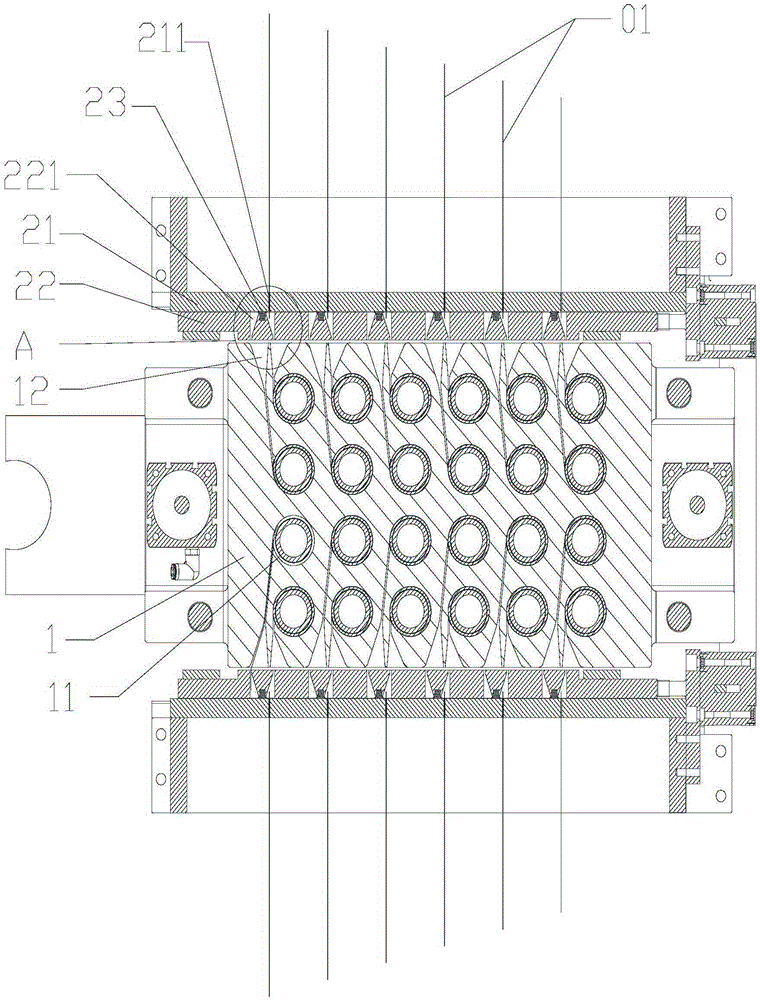

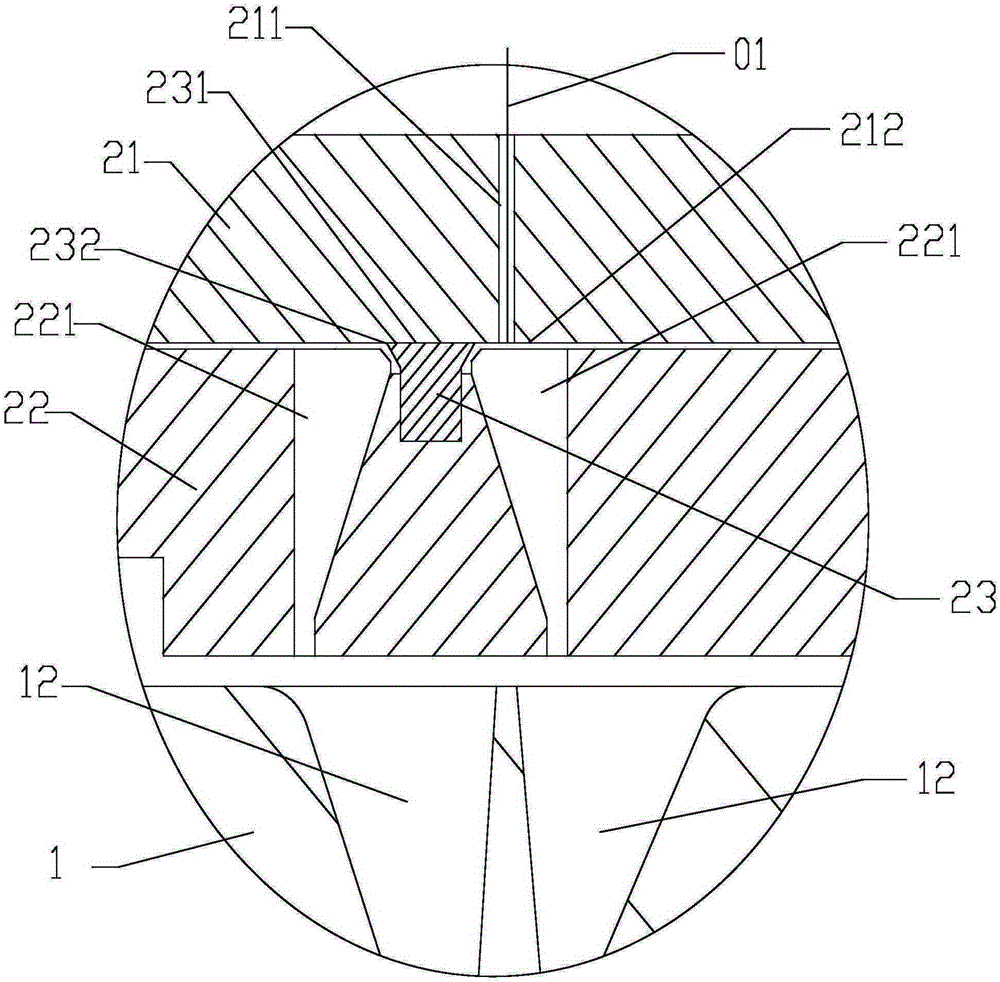

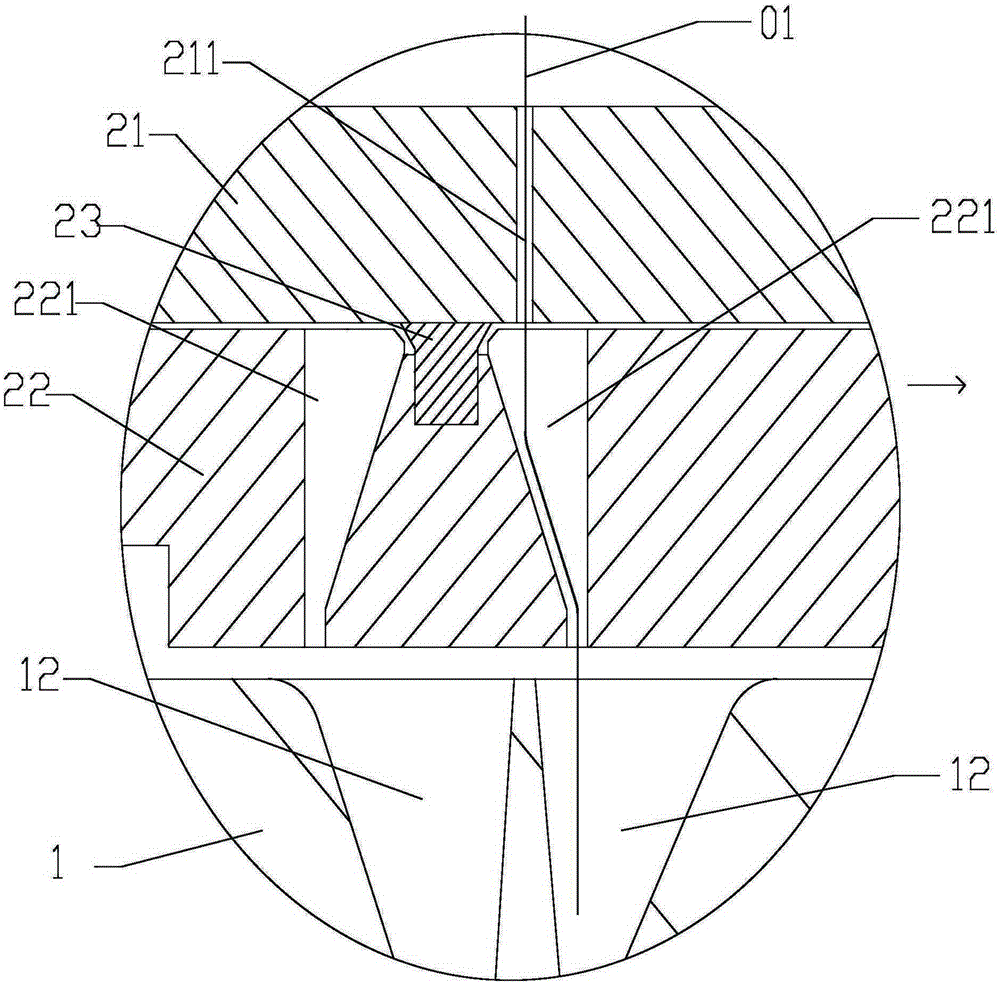

[0014] Such as figure 1 and 2 Shown is the preferred embodiment of a kind of standard cutting device of the present invention, and this standard cutting device is mainly made up of entering standard mold 1 and standard cutting assembly, and cutting standard assembly is positioned at the side of entering standard mold 1, and entering standard mold 1 is provided with mold Core holes 11 and guide channels 12, each core hole 11 is a round through hole structure, each core hole 11 is connected to a guide channel 12, and the guide channel extends to the side of the edge of the standard die and enters the standard die The sides of the edge form guide inlets, and the marking paper can enter the guide passage from the guide inlet and enter the core hole 11 along the guide passage. In this embodiment, the function of the standard feeding die is to store the cut standard paper, restrict the standard paper in the core hole 11 and curl the standard paper, and then carry the standard paper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com