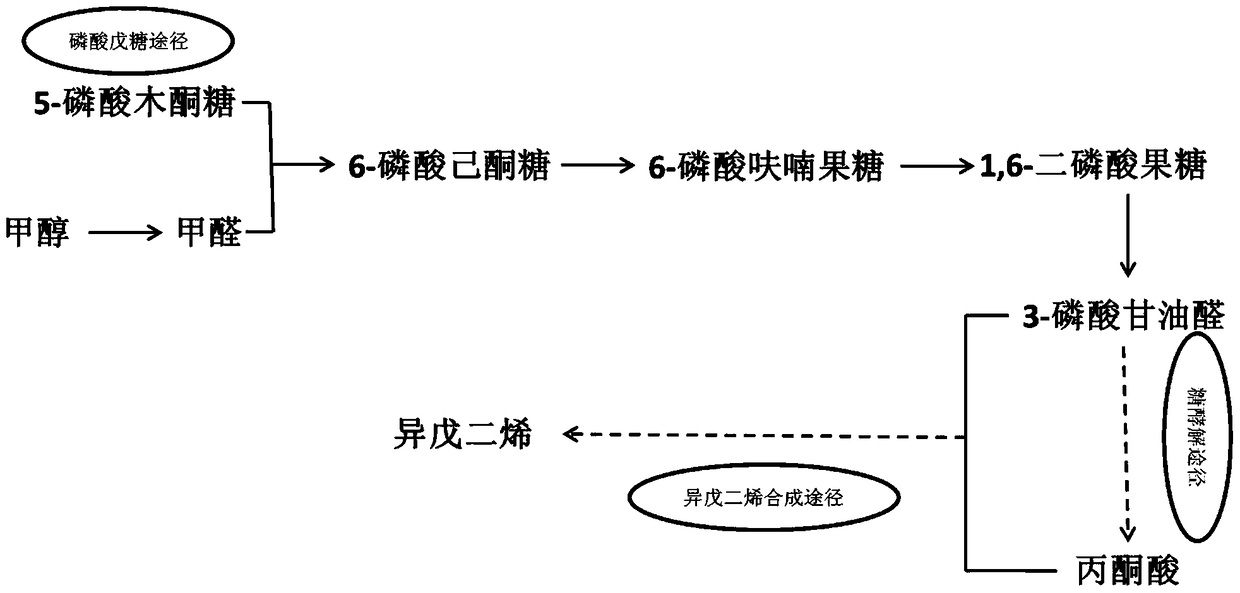

A kind of Escherichia coli genetically engineered bacteria that catalyzes methanol to prepare isoprene and its preparation method and application

A technology of genetically engineered bacteria and isoprene, applied in the field of genetic engineering, can solve the problems of high glucose market price, large fluctuations, low yield and yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The acquisition of embodiment 1 gene

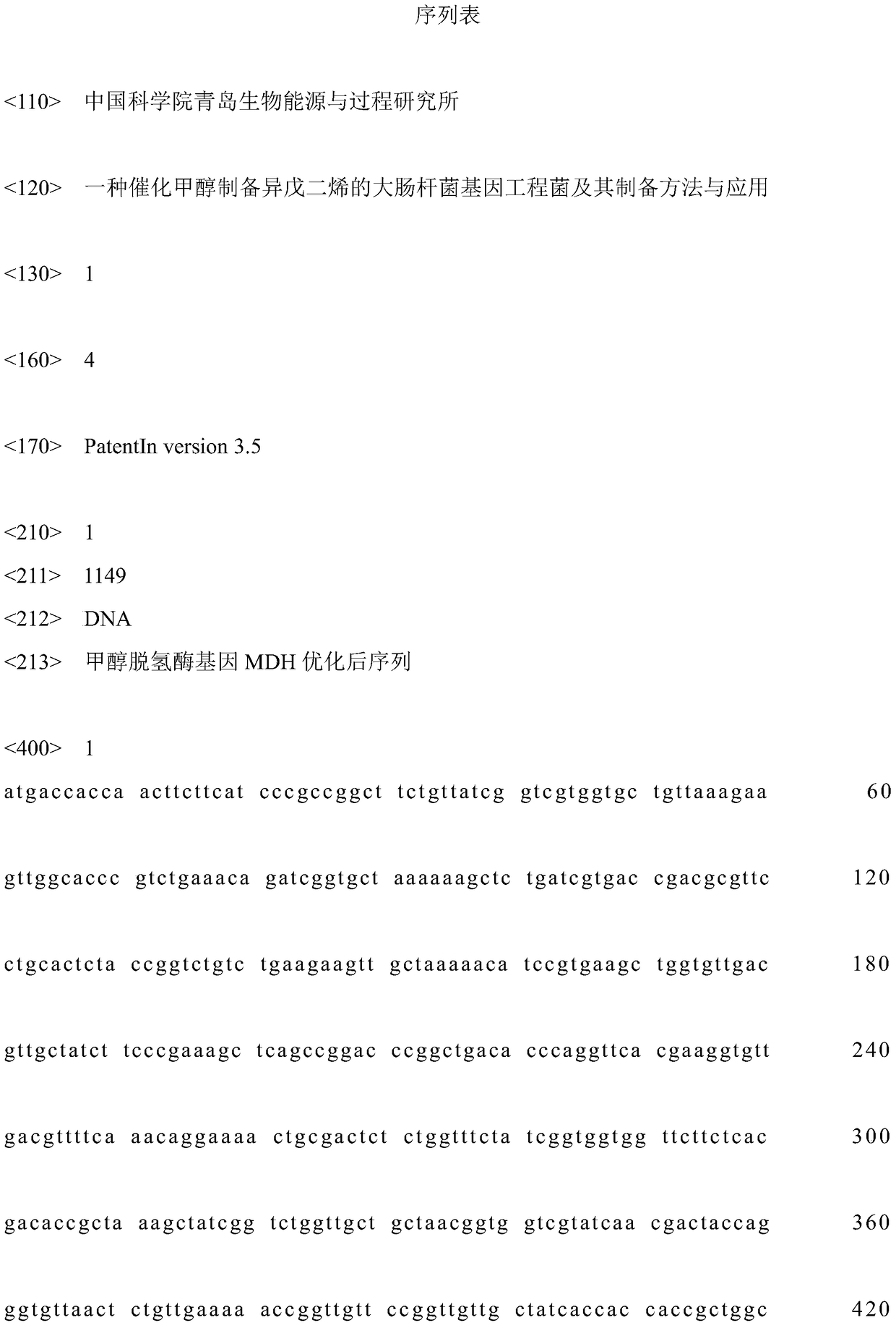

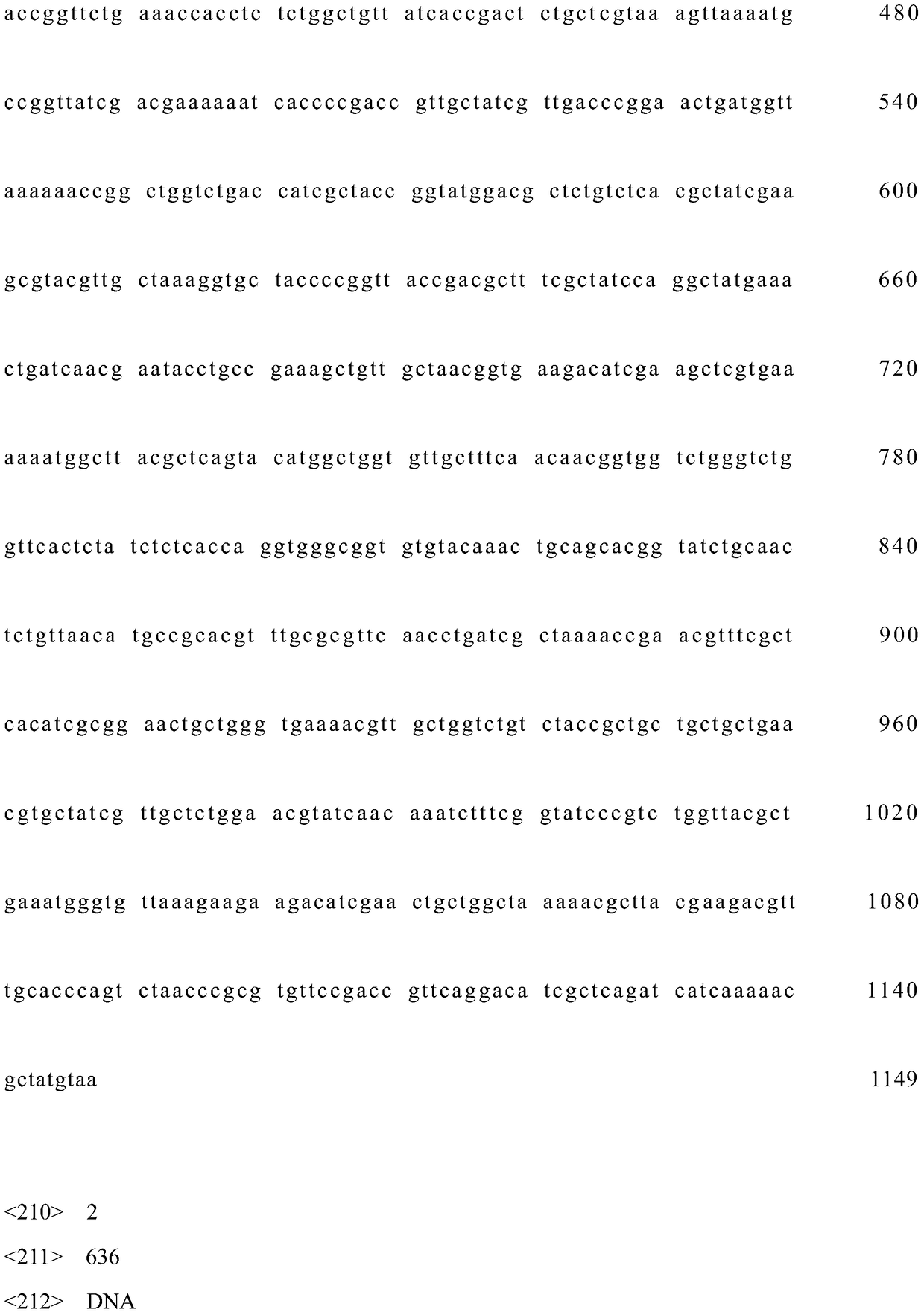

[0041] In this embodiment, the gene sequence of methanol dehydrogenase gene MDH (gene accession number GI: 662720579) derived from methylotrophic Bacillus; ) gene sequence; the gene sequence of 6-phosphate-3-ketulose isomerase gene RmpB (gene accession number GI: 40074228); the gene sequence of methanol dehydrogenase activating protein gene ACT (gene accession number GI: 22654851) . The original sequences of the above genes were codon-optimized and synthesized by Suzhou Jinweizhi Biotechnology Co., Ltd. The sequence of the optimized methanol dehydrogenase gene MDH is shown in SEQ ID NO.1; the sequence of the optimized 6-ketohexose phosphate synthase gene RmpA is shown in SEQ ID NO.2; the optimized 6-phosphate-3- The sequence of the ketohexose isomerase gene RmpB is shown in SEQ ID NO.3; the sequence of the optimized methanol dehydrogenase activating protein gene ACT is shown in SEQ ID NO.4.

Embodiment 2

[0042] The preparation of embodiment 2 recombinant plasmids

[0043] Digest the methanol dehydrogenase gene MDH and plasmid pBAD18 obtained in Example 1 with EcoRI and SacI, and recover the target fragment with a gel recovery kit. After recovering the digested product, mix the carrier:target fragment at a molar ratio of 1 :1 ratio mix, add T 4 After DNA ligase, ligate at 16°C for 6 hours to obtain recombinant plasmid pBAD18-1;

[0044] The 6-ketohexose phosphate synthase gene RmpA obtained in Example 1 and the plasmid pBAD18-1 were digested with SacI and KpnI, and the target fragment was recovered with a gel recovery kit. After the digested product was recovered, the vector: The fragments were mixed at a molar ratio of 1:1, and ligated at 16°C for 6 hours after adding T4 DNA ligase to obtain the recombinant plasmid pBAD18-2;

[0045] The 6-phosphate-3-ketulose isomerase gene RmpB obtained in Example 1 and the plasmid pBAD18-2 were digested with SalI and SphI, and the target ...

Embodiment 3

[0047] Example 3 Introducing the plasmid pBAD18-3 and the isoprene synthesis plasmid into Escherichia coli E.coli JM109(DE3) to synthesize isoprene

[0048] Add the recombinant plasmid pBAD18-3 obtained in Example 2 and the isoprene synthesis plasmid to E.coliJM109 (DE3) competent cells at the same time; ice-bath for 20 minutes, put the competent cells in a 42°C water bath to heat Shock for 45 s, and immediately ice-bath for 2 min after heat shock; add 600 μl sterilized LB liquid medium to the centrifuge tube where the competent cells are in the ultra-clean bench; place the centrifuge tube at 37°C for 1 h on a shaker; shaker culture Afterwards, centrifuge at 500rpm for 2min, suck out the supernatant with a pipette gun, leave a little supernatant to resuspend the cells, and spread it on the LB solid plate containing kanamycin and chloramphenicol; place the coated plate at 37 ℃ constant temperature incubator, and continue to cultivate until a single clone grows.

[0049] Add th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com