Metallographic corrosive agent and method for nickel-vanadium alloy

A nickel-vanadium alloy and metallographic corrosion technology, which is applied in the field of metallographic corrosion, can solve the problems of difficult identification of precipitated phase, observation of metallographic structure and identification of adverse effects, blurred observation surface, etc., and achieve the effect of efficient corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

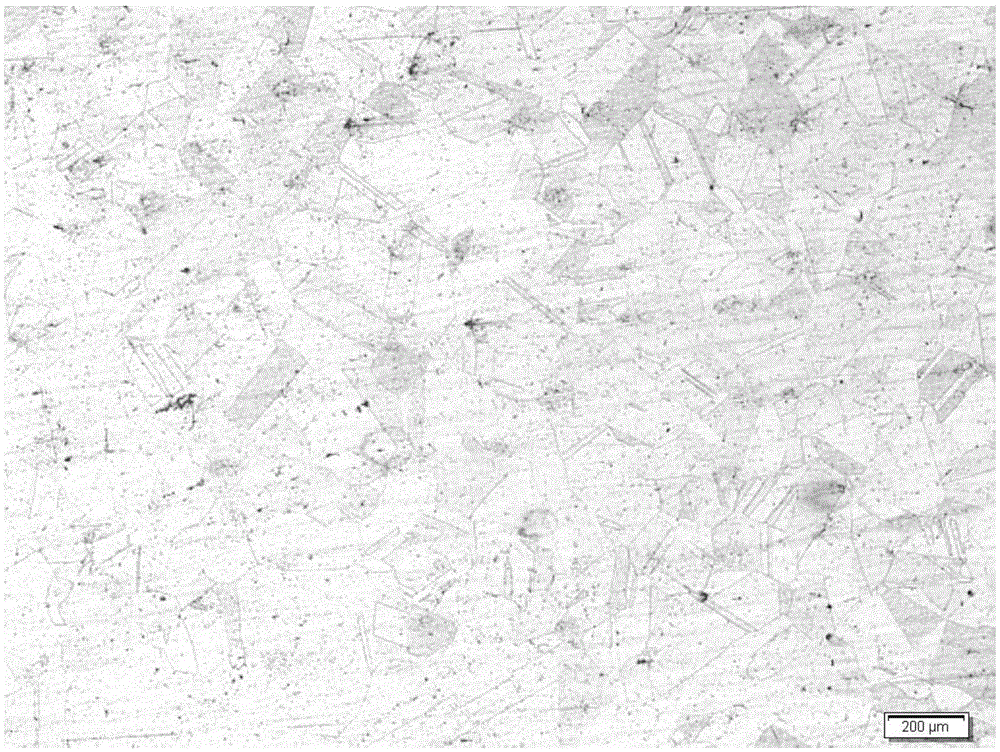

[0033] ① First add 10L of 30wt% hydrogen peroxide to the container, then add 10L of 68wt% nitric acid and 80L of 36% hydrochloric acid in sequence, stir and let it stand for 10 minutes to obtain the corrosion solution;

[0034] ②Heating the corrosive agent obtained in step ① to 90°C and keeping it warm;

[0035] ③Immerse the polished nickel-vanadium alloy sample completely in the corrosion solution once, and take it out after 10s;

[0036] ④ Rinse the sample taken out with water for 1 min;

[0037] ⑤ Wipe the washed sample with alcohol cotton and let it dry naturally to obtain sample A.

Embodiment 2

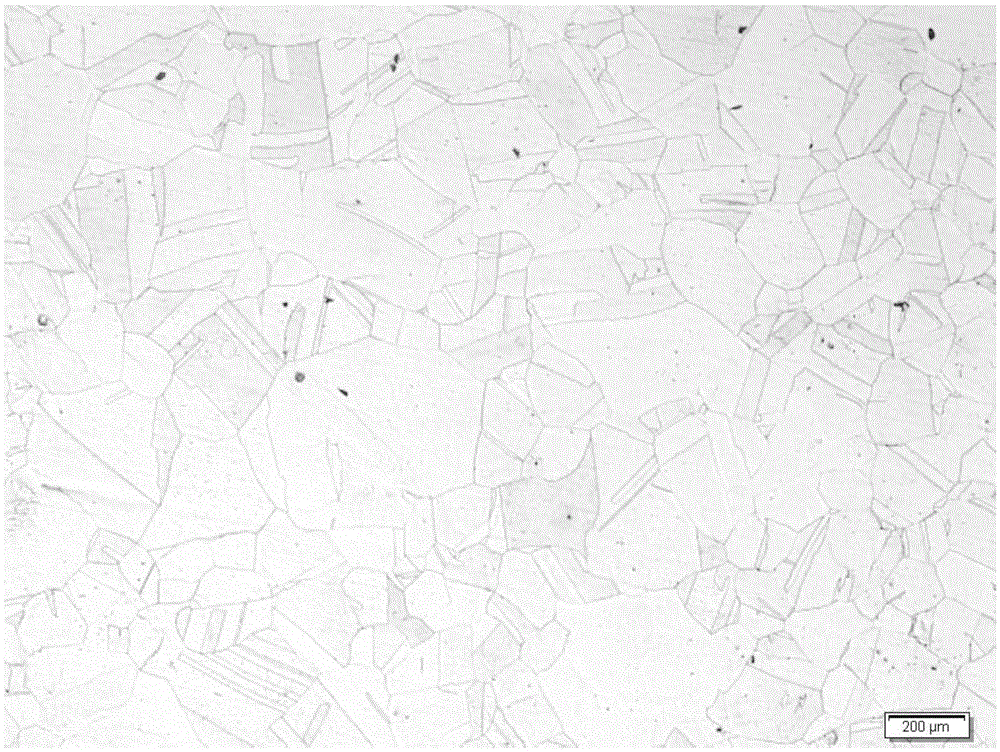

[0039] ① First add 15L of 50wt% hydrogen peroxide to the container, then add 15L of 65wt% nitric acid and 70L of 38% hydrochloric acid in sequence, stir and let it stand for 12 minutes to obtain the corrosion solution;

[0040] ②Heating the corrosive agent obtained in step ① to 88°C and keeping it warm;

[0041] ③ Completely immerse the polished nickel-vanadium alloy sample in the corrosion solution for 2 times, each time for 20s, and take it out;

[0042] ④ Rinse the sample taken out with water for 2 minutes;

[0043] ⑤Wipe the washed sample with alcohol cotton and dry it with an air gun to obtain sample B.

Embodiment 3

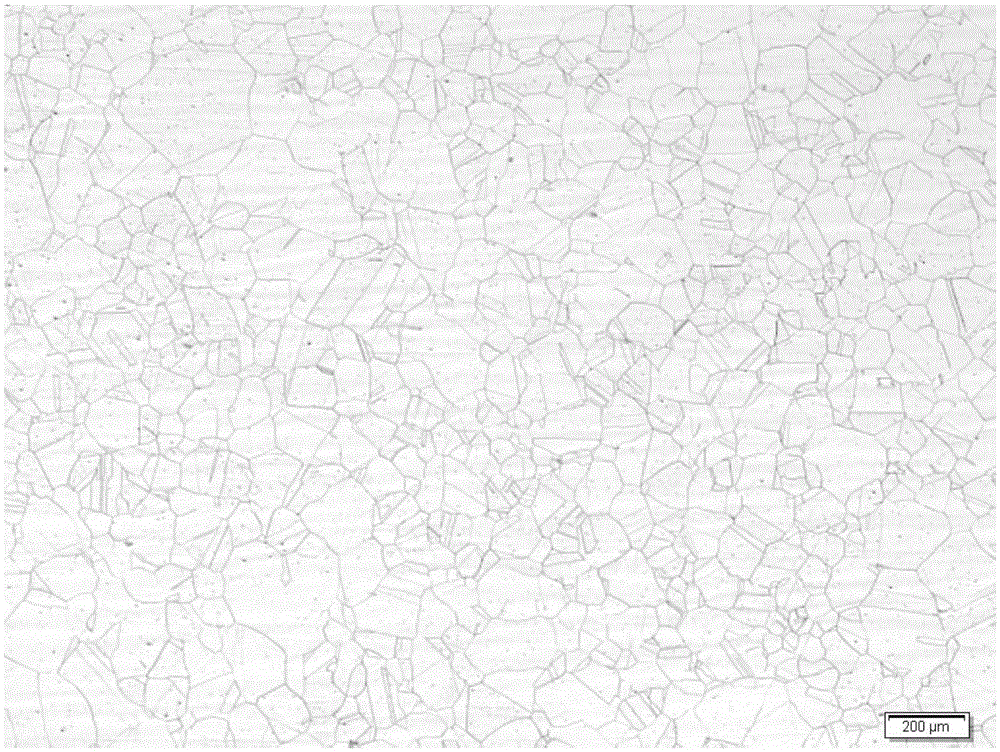

[0045] ① First add 12.5L of 30wt% hydrogen peroxide to the container, then add 12.5L of 67wt% nitric acid and 75L of 37% hydrochloric acid in sequence, stir and let it stand for 10 minutes to obtain the corrosion solution;

[0046] ②Heating the corrosive agent obtained in step ① to 90°C and keeping it warm;

[0047] ③ Completely immerse the polished nickel-vanadium alloy sample in the corrosion solution for 2 times, each time for 15s, and take it out;

[0048] ④ Rinse the sample taken out with water for 1.5 minutes;

[0049] ⑤ Wipe the washed sample with alcohol cotton and dry it with an air gun to obtain sample C.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap