Lifting supporting wheel assembly and cantilever sliding door

A technology of supporting wheels and lifting wheels, which is applied in the field of translation doors, can solve problems such as loss of appearance, affecting the visual effect of suspension, and damage to the door body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

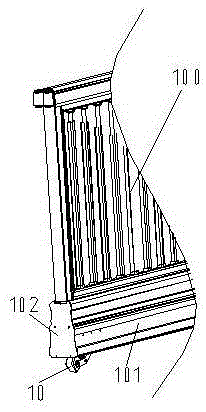

[0029] like figure 1 As shown, the cantilever translation door includes a cantilever door body 100, a translation door machine and a supporting device. The bottom beam 101 of the cantilever door body 100 is made of a multi-cavity hollow profile, and the bottom of the lower chamber of the bottom beam 101 is provided with strip-shaped openings along the length direction. The supporting device comprises two sliding supporting wheels and a lifting supporting wheel assembly 10 .

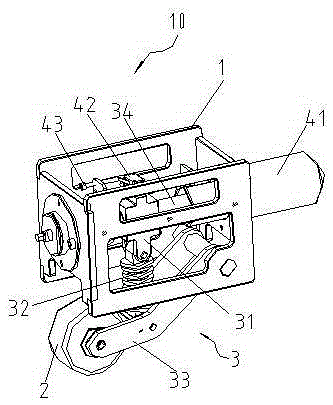

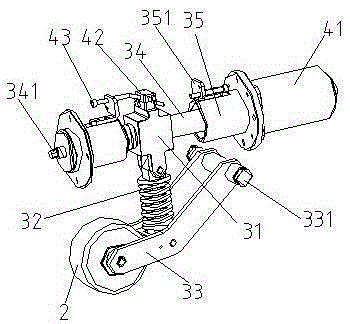

[0030] The lifting support wheel assembly 10 can be produced, transported and sold separately; it can be conveniently installed on the front end of the cantilever door body 100 during use, that is, the end away from the sliding support wheel, and then sealed in the bottom beam 101 by the side cover 102 . like figure 2 As shown, the lifting support wheel assembly 10 includes a box body 1, a lifting wheel 2, a slider crank mechanism 3, a driving mechanism and a power supply mechanism.

[0031] The box ...

Embodiment 2

[0050] In the second embodiment, except that the elastic connecting rod is replaced with a rigid structure, other structures are the same as in the first embodiment. For the same structures as those in the first embodiment, the second embodiment uses the same numbers.

[0051] like Figure 9 As shown, the connecting rod 36 is a rigid rod-like structure.

[0052] If the length of the cantilever door body 100 is short, since the front end of the door body is closer to the sliding support wheel during operation, it is not easy to sag and deform, so it is not necessary to let the lifting wheel 2 move against the ground when the door body is opened or closed. , so that the lifting wheel 2 can be raised when the door body is about to be opened, or the lifting wheel 2 is put down when it is closed in place, although the rigid connecting rod 36 does not have a buffering effect, it will not affect the smooth operation of the door body. In addition, if the lifting wheel 2 moves agains...

Embodiment 3

[0054] In the third embodiment, except that the elastic connecting rod is replaced with a rigid structure; and the single lifting wheel is replaced with a double-wheel structure, and the shapes of the connecting rod and the crank are adjusted accordingly, other structures are the same as in the first embodiment. For the same structures as those in the first embodiment, the third embodiment uses the same numbers.

[0055] like Figure 10 As shown, there are two lifting wheels 6, which are connected together by the lifting wheel shaft 61, and are more stable when supported on the ground.

[0056] The connecting rod 37 is a rigid flat rod-shaped structure, and its upper end is hinged on the lower end of the slide block 31 , and the lower end of the connecting rod 37 is hinged with the middle part of the lifting wheel shaft 61 . The crank 38 is in the shape of a curved arm with an obtuse upper and lower portion. The upper end of the crank 38 is rotatably sleeved on the crank sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com