Method for mining pressed coal below shallow buried gas delivery pipelines

A technology of gas transmission pipeline and mining method, which is applied in underground mining, surface mining, earthwork drilling and other directions, can solve the problems affecting the sustainable development of mining areas, waste of coal resources, and the impact of development methods, and achieves simple procedures, simple erection, Highly economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the drawings.

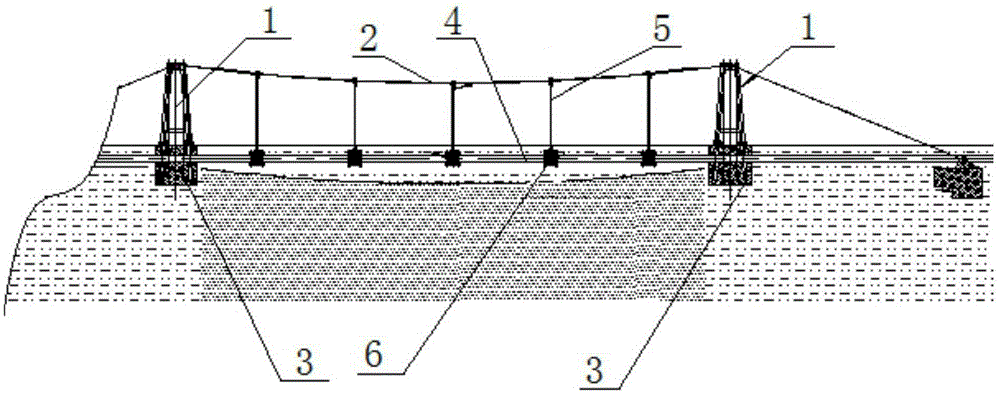

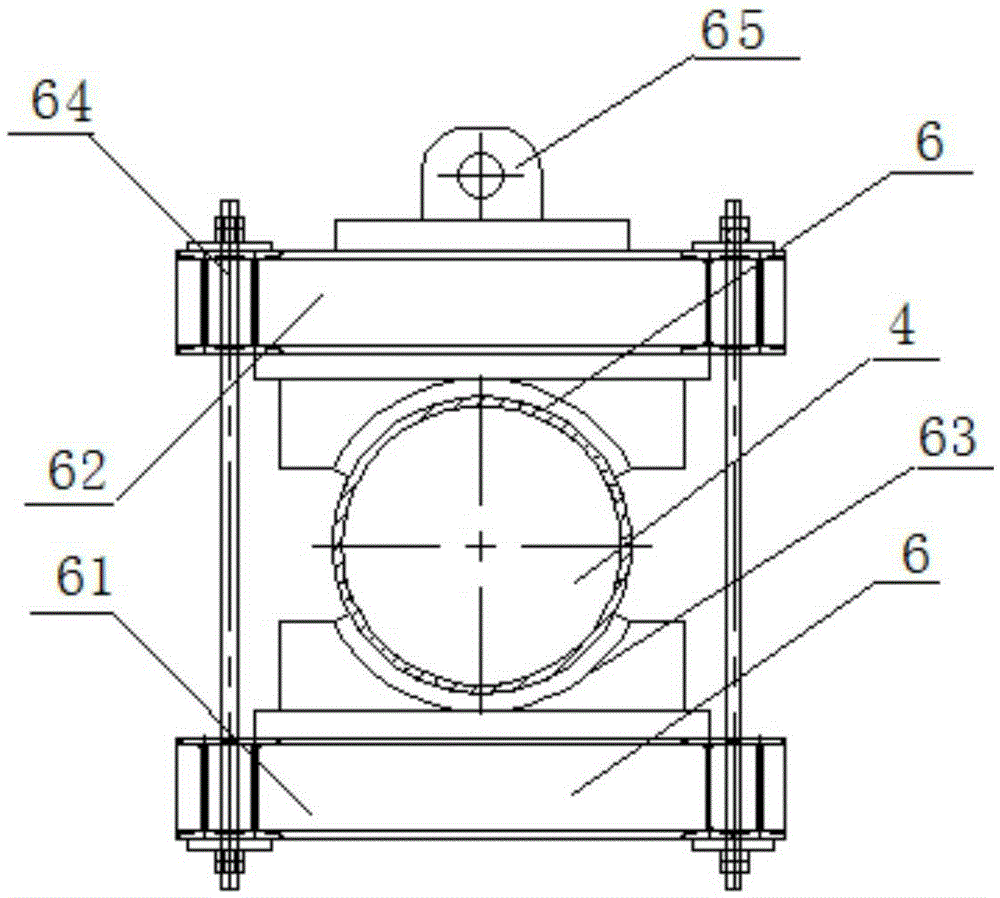

[0029] A method for mining compressed coal under a shallow buried gas pipeline includes the following steps:

[0030] a. Determine the movement and deformation parameters of the shallow buried gas pipeline based on the observation data of surface movement after coal resources in other areas of the mining area, and use the probability integral method to establish the surface subsidence curve equation W to predict the surface subsidence along the pipeline direction after resource mining;

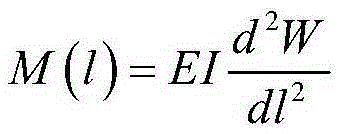

[0031] b. Calculate the bending moment and maximum bending stress of buried pipelines according to the above surface subsidence curve equation

[0032] According to the bending theory of the continuous beam, the calculation equation for the bending moment of the buried pipeline is:

[0033] M ( l ) = E I d 2 W dl 2

[0034] In the formula, E is the tensile elastic modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com