Oil-gas separation system for oil injection screw vacuum pump

A screw vacuum pump and separation system technology, which is applied to the components of the pumping device for elastic fluid, pump components, rotary piston type/swing piston type pump components, etc., can solve the problem of high equipment maintenance cost and reduce maintenance. Cost, reduced requirements, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

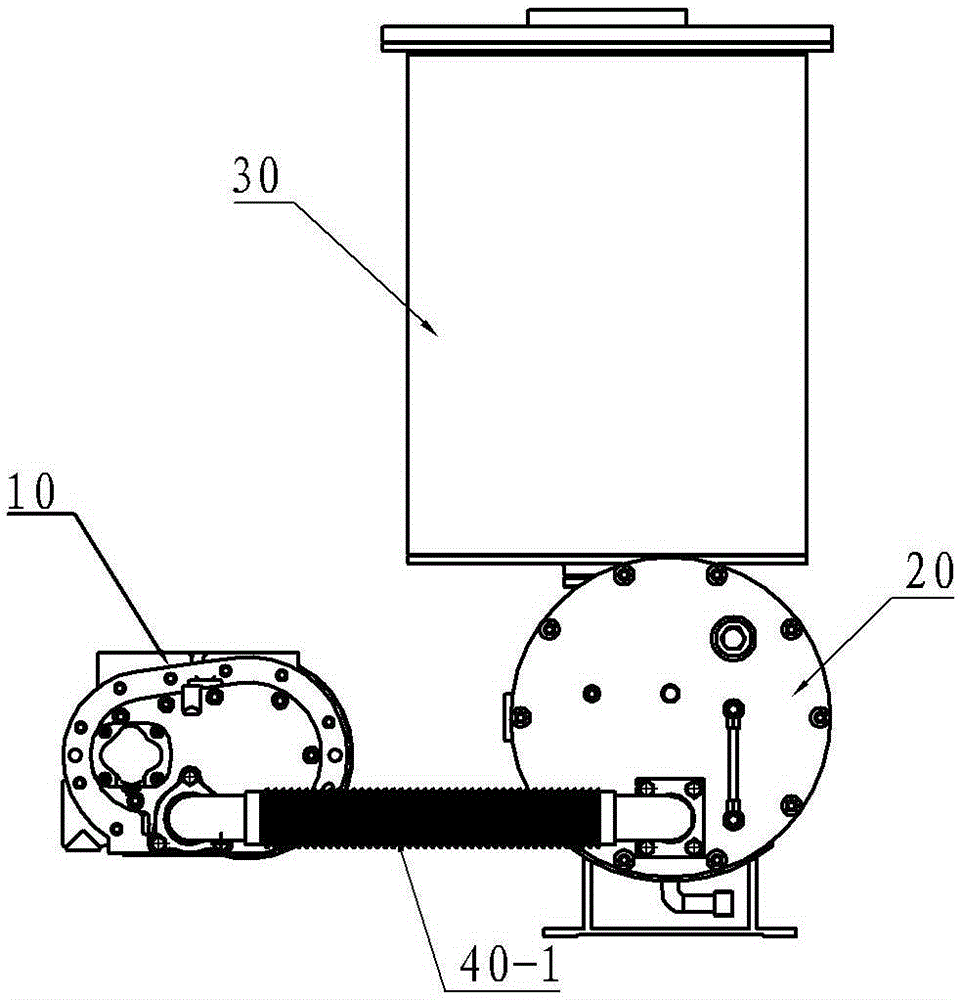

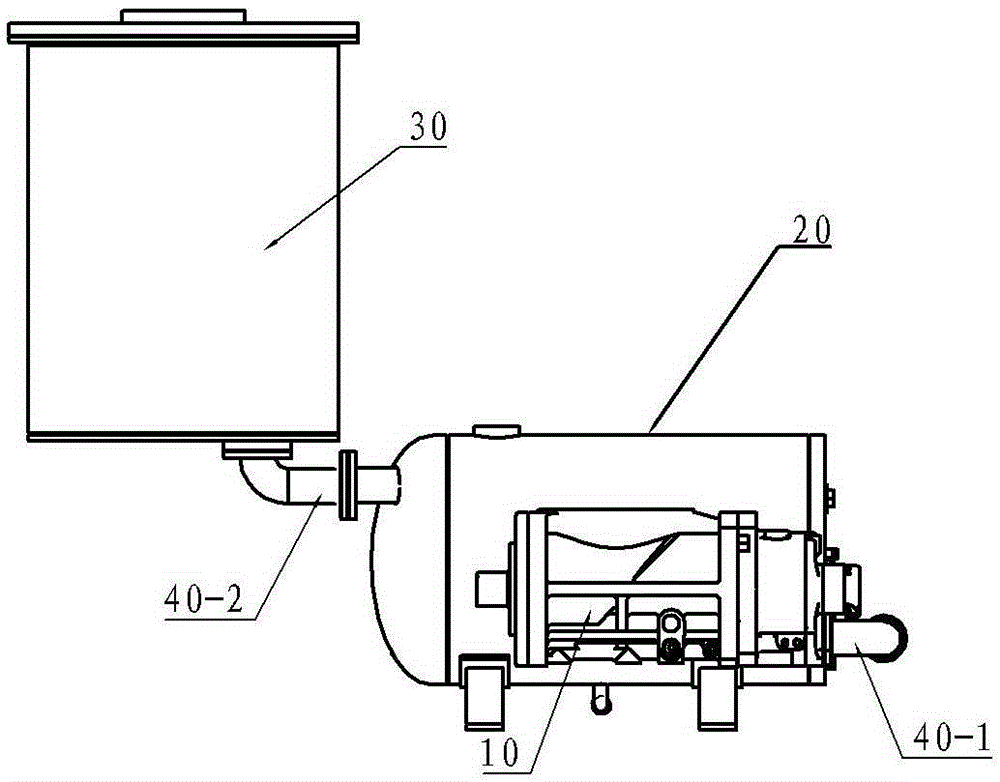

[0022] See figure 1 and figure 2 , the present invention is used for the oil-gas separation system of an oil-injected screw vacuum pump, which includes an oil-injected screw vacuum pump host 10 and a fine separator 30, and a rough separator 20 is also arranged between the oil-injected screw vacuum pump host 10 and the fine separator 30, The oil-injected screw vacuum pump 10 , the rough separator 20 and the fine separator 30 are respectively connected through exhaust connecting pipes 40 in sequence.

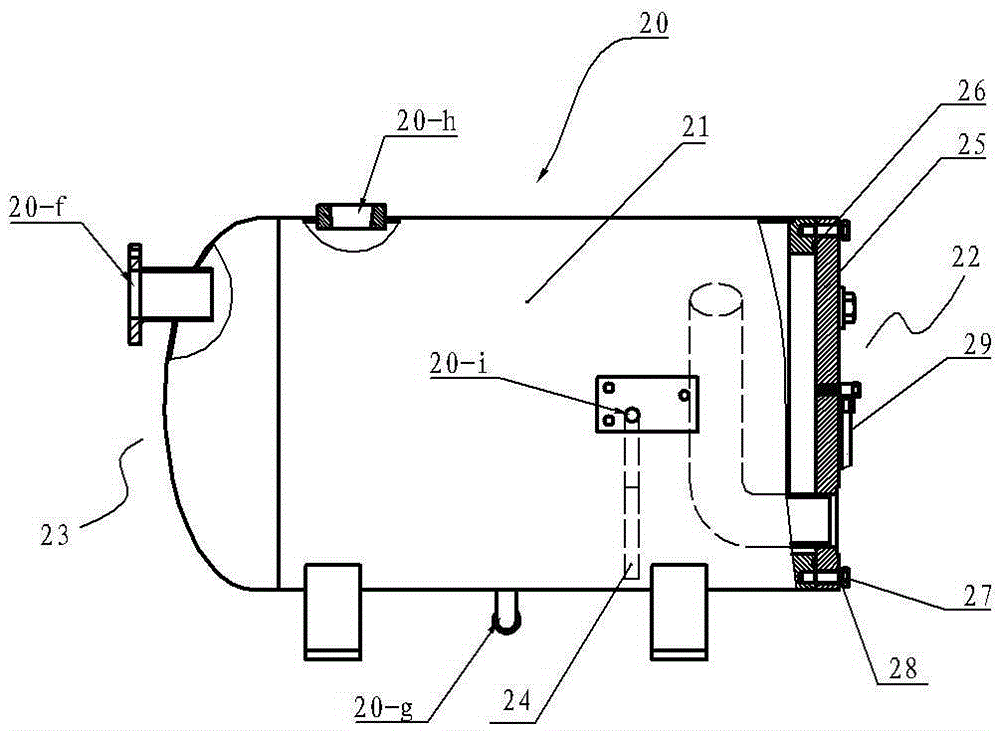

[0023] Wherein, the coarse separator 20 comprises a coarse separator cylinder 21, see image 3 and Figure 4 , the two sides of the coarse separator cylinder 21 are respectively the coarse air inlet end 22 sealed by the end cover 25 and the coarse exhaust outlet end 23 integrally provided with the coarse separator cylinder 21, wherein the end cover 25 It is sealed with the coarse separator cylinder 21 by an O-ring 26 and fixed by bolts 27 and gaskets 28; the coarse air inlet e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com