Screw connecting device for installation hole with deep cavity

A screw connection and mounting hole technology, which is applied in the direction of screws, connecting members, pins, etc., can solve the problems of invisible screw assembly state, unfastened assembly, and screw deviation, so as to reduce the defective rate of product engineering and screw installation The effect of stable position and easy positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

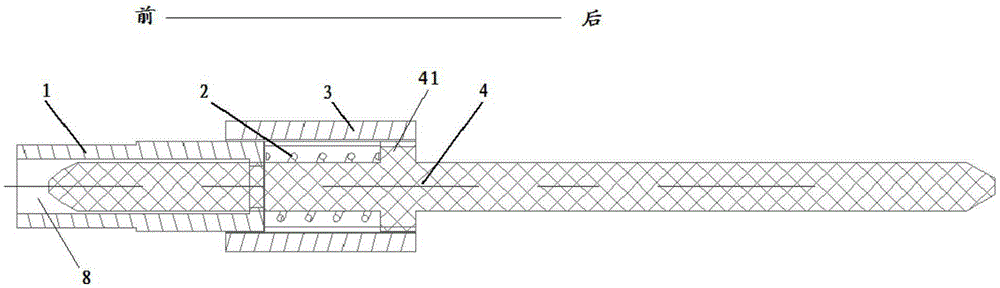

[0026] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

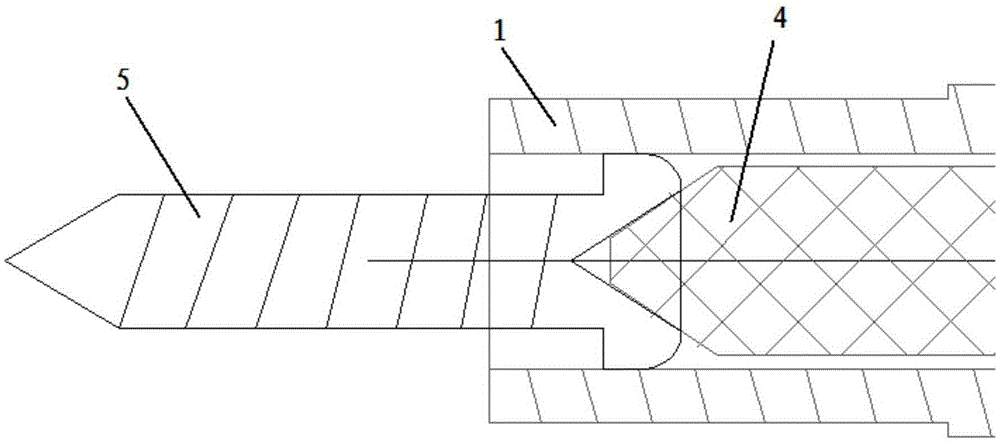

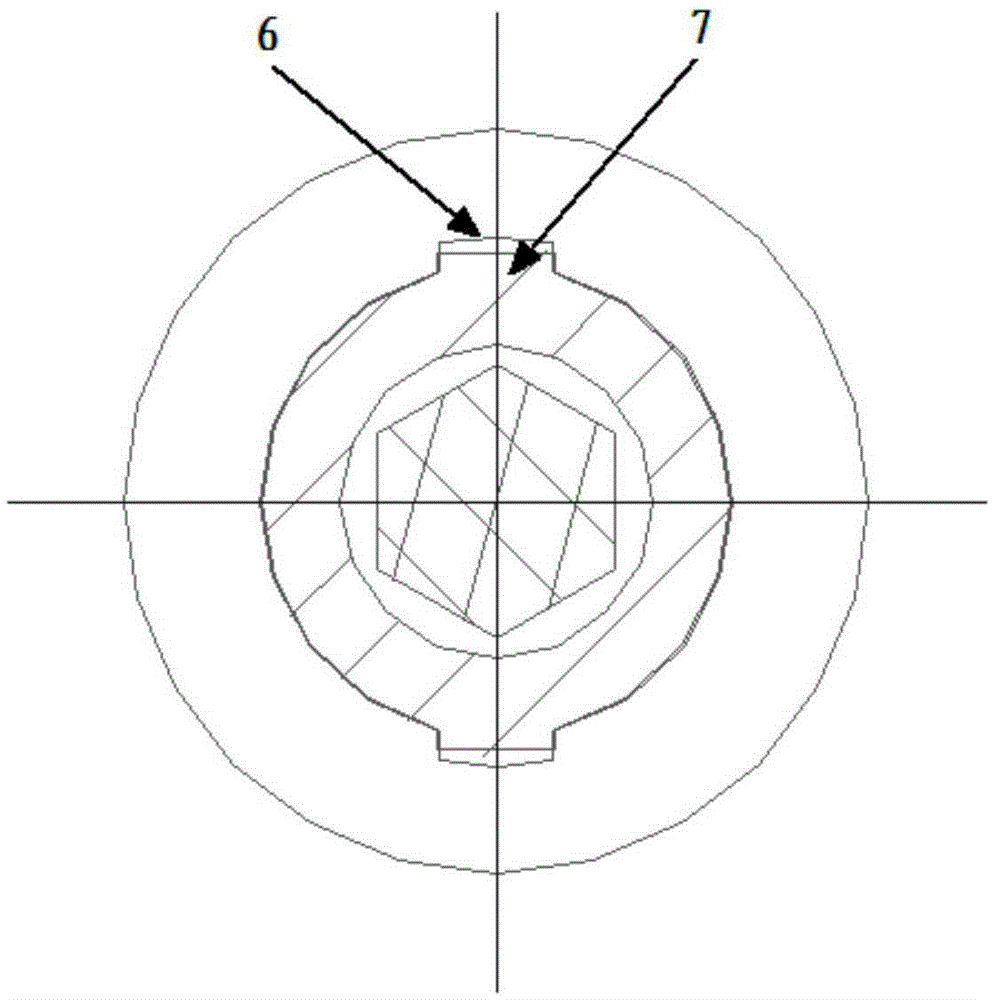

[0027] The invention is a screw connection device with a deep cavity mounting hole, such as Figures 1 to 3 As shown, it includes a screw mounting part 1 for temporarily accommodating screws, a first through hole 8 is provided from the front end of the screw mounting part 1 to its rear end, and the front part of the first through hole 8 is suitable for the nut shape structure of the screw Matching, that is to say, during installation, the screw cap is located at the front of the first through hole and can temporarily fix the screws to be installed through friction with the side wall of the first through hole;

[0028] The locking member 3 is provided with a second through hole 9, the rear end of the screw mounting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com