Internal meshing epicyclic gear train type variable flywheel

An epicyclic gear train, internal meshing technology, applied in the field of flywheel, to achieve the effect of easy frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

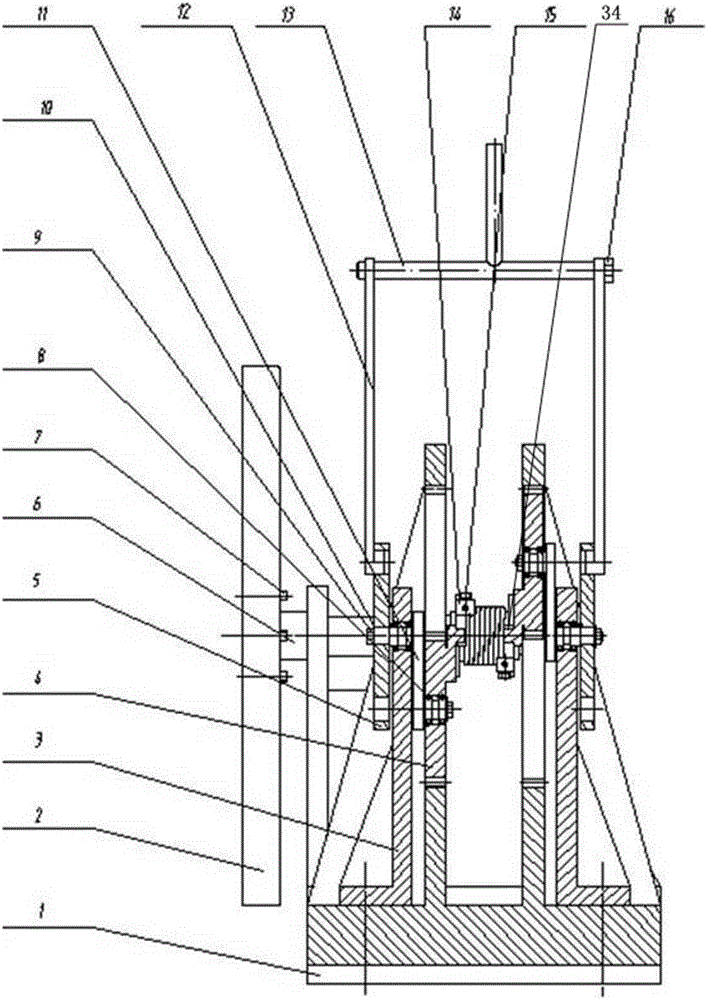

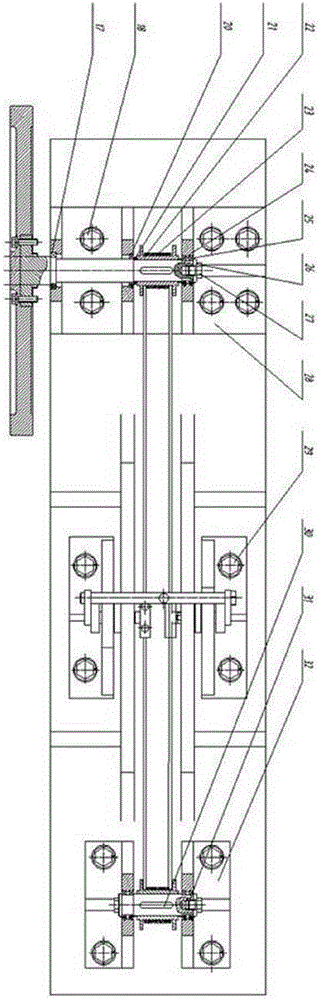

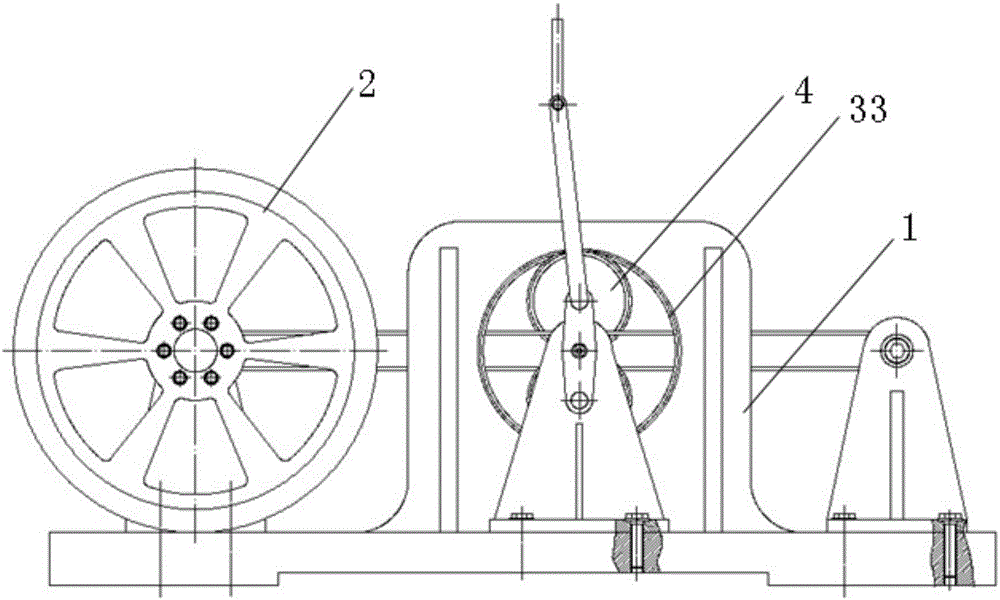

[0029] Such as Figure 1-4 As shown, an internal meshing epicyclic train type variable flywheel includes a frame 1, on which a flywheel frame 28, a gear frame 28 and a roller frame 32 are sequentially arranged, and on the frame 1 are also provided with two An internal gear 33 also includes a flywheel assembly, a gear assembly, a motion conversion assembly and a drive assembly; wherein:

[0030] Described flywheel assembly comprises flywheel shaft 6, and described flywheel shaft 6 is installed on the flywheel frame 28 through flywheel bearing 17 and second bearing 20, and described flywheel shaft 6 is installed with collar 24, cylinder 22, Flywheel collar 21 and flywheel 2;

[0031] The gear assembly includes two planetary gears 4 and a crankshaft 11, the two planetary gears 4 mesh with two internal gears 33 respectively, and the two planetary gears 4 are symmetrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com