Stable anti-leakage lubricating gate valve

A leak-proof, gate valve technology, applied in the direction of sliding valves, valve devices, engine components, etc., can solve the problems of short structural length, medium leakage at the valve stem seal, and difficulty in leakage treatment, so as to improve stability, prevent gate valve leakage, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described below in conjunction with accompanying drawing.

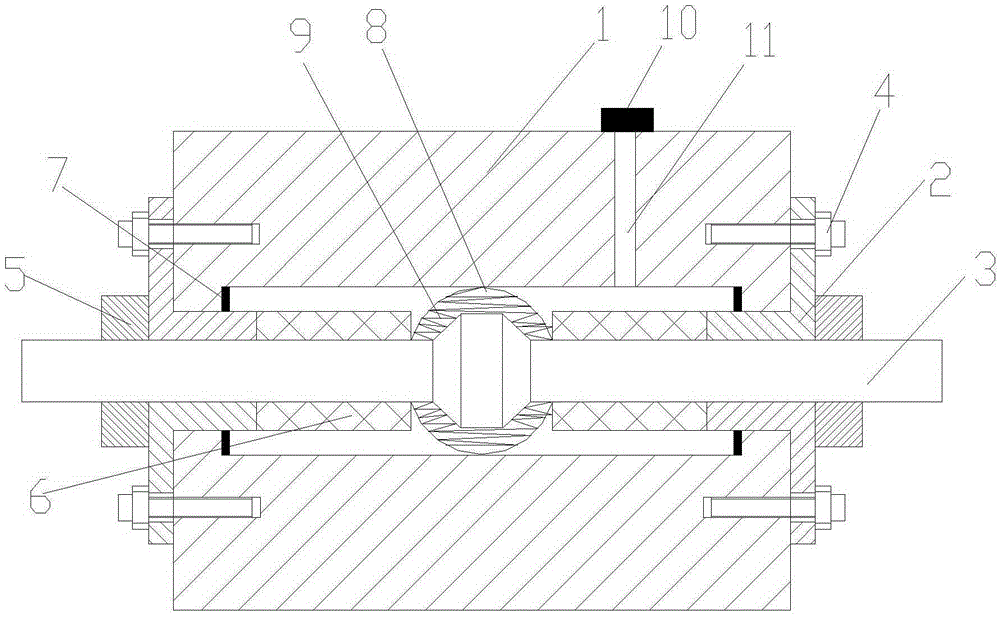

[0013] attached figure 1 It is a smooth and leak-proof lubricating gate valve according to the present invention, which includes a housing 1, a valve cover 2 and a spherical valve stem 3; the valve cover 2 is fixedly connected to the housing 1 by bolts 4; the spherical valve stem 3 Installed in the housing 1, and both ends protrude from the valve cover 2; the valve cover 2 is provided with a locking ring 5 at the protruding end of the spherical valve stem 3; the part of the spherical valve stem 3 in the housing 1 A reinforcing ring 6 is installed; the valve cover 2 is installed on the inner side of the housing 1 and a sealing ring 7 is installed; the spherical valve stem 3 is installed outside the middle part of the housing 1 with a stabilizing cover 8; the stabilizing cover 8 There is a stabilizing spring 9 inside; the number of the reinforcement ring 6 is two, and it is made of wear-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com