Patents

Literature

39results about How to "Prevent media leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

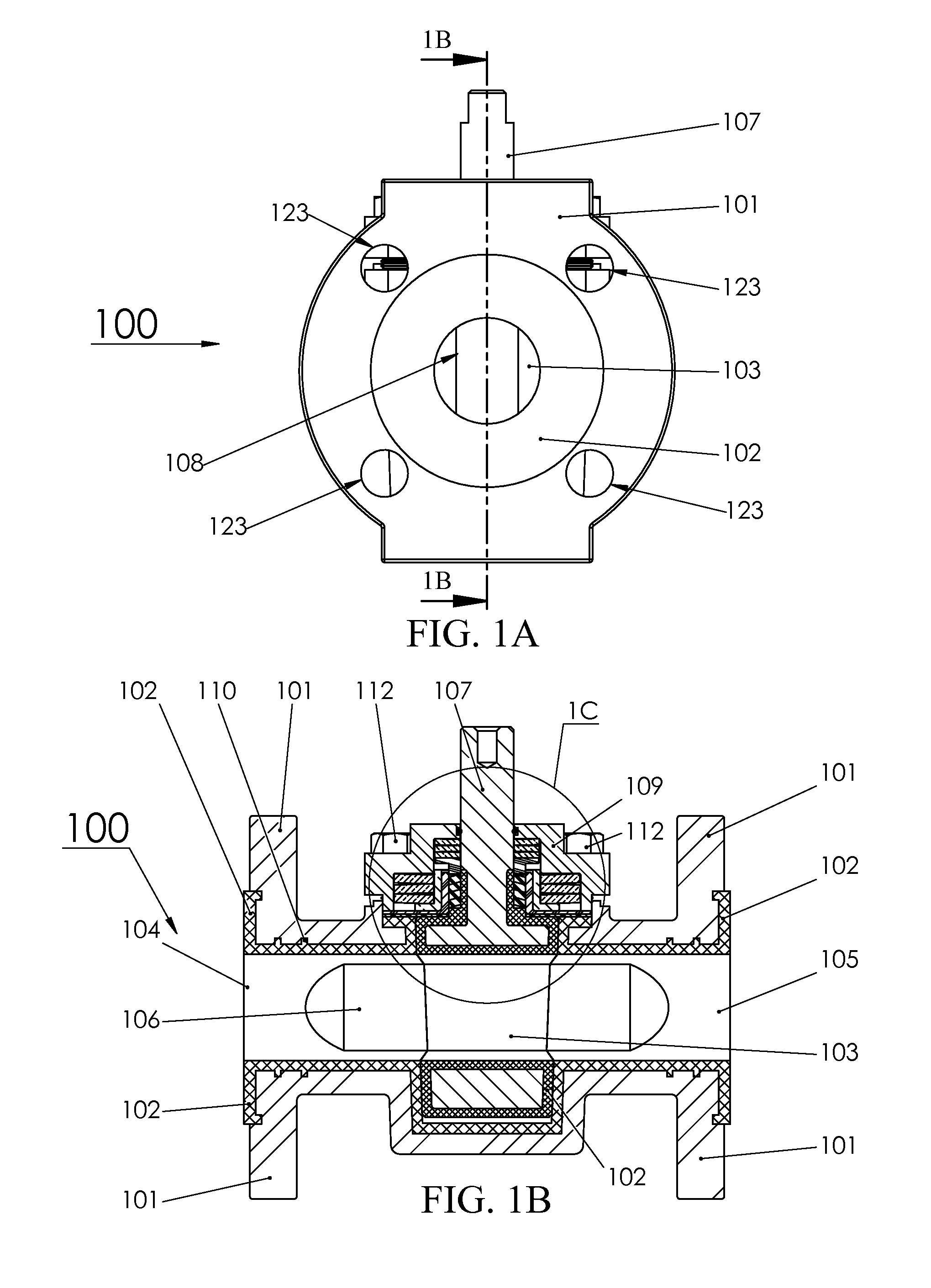

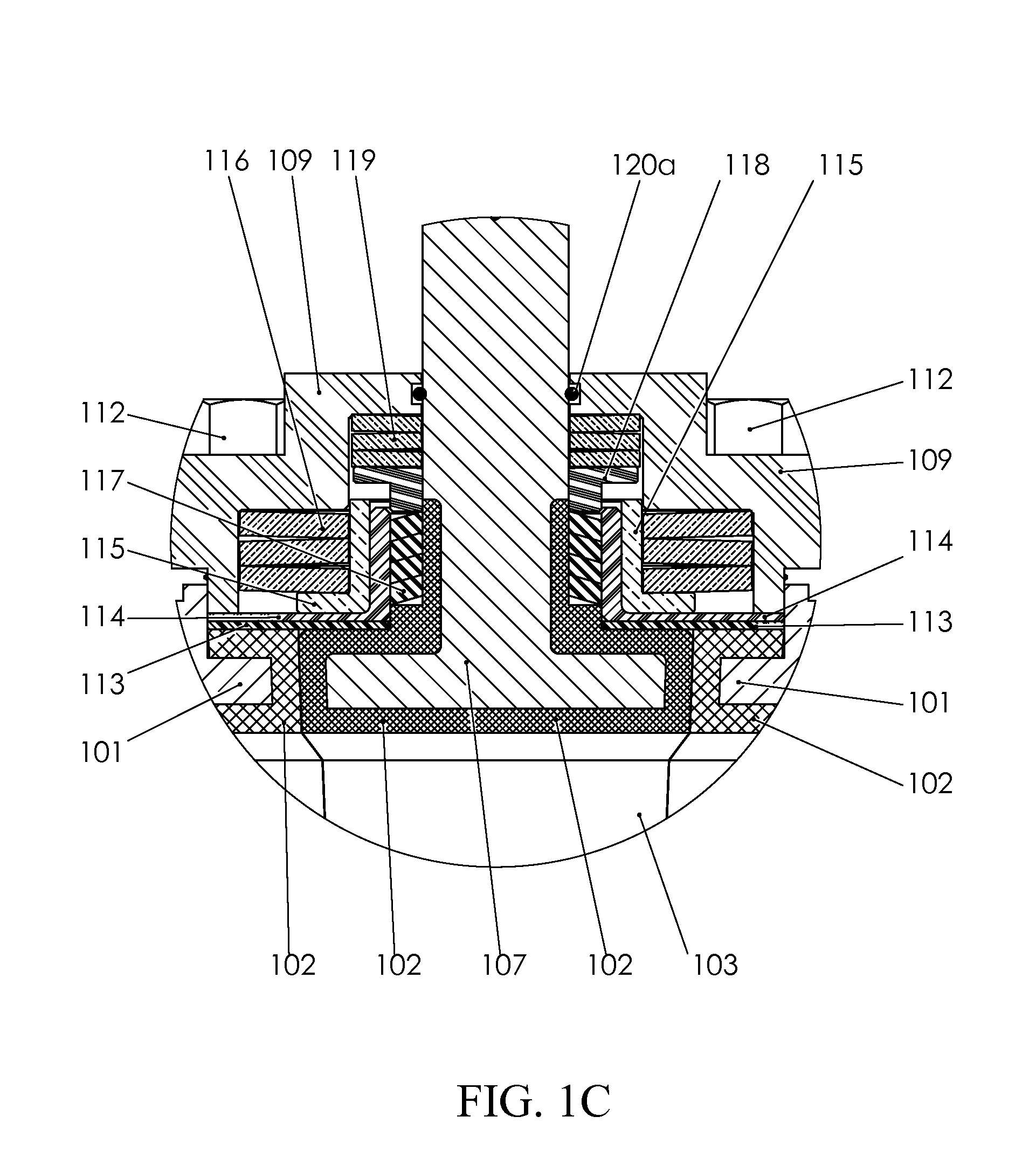

Plug valve and stem sealing assembly

ActiveUS20130270472A1Prevent leakageImprove reliabilitySpindle sealingsPlug valvesEngineeringVALVE PORT

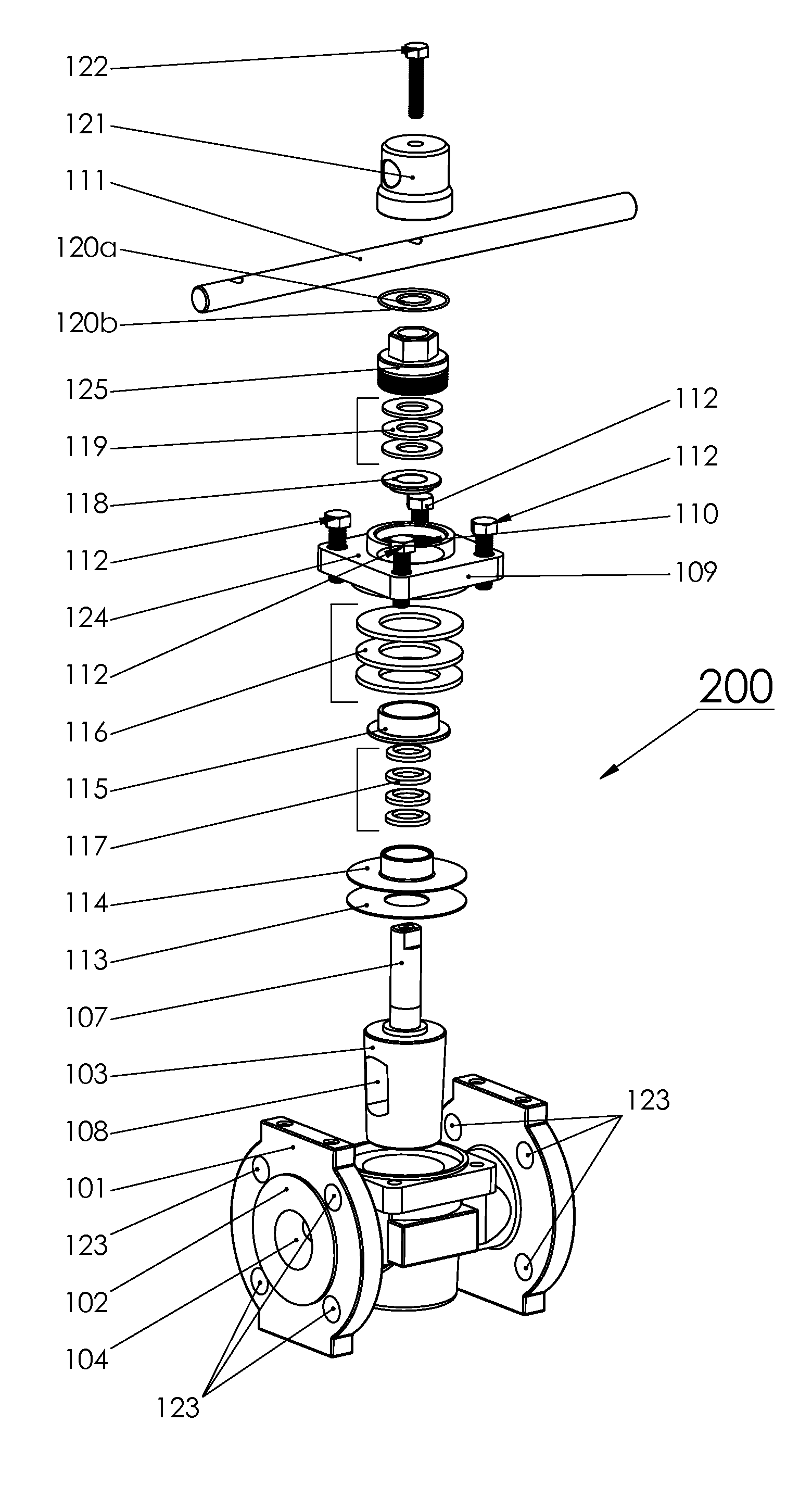

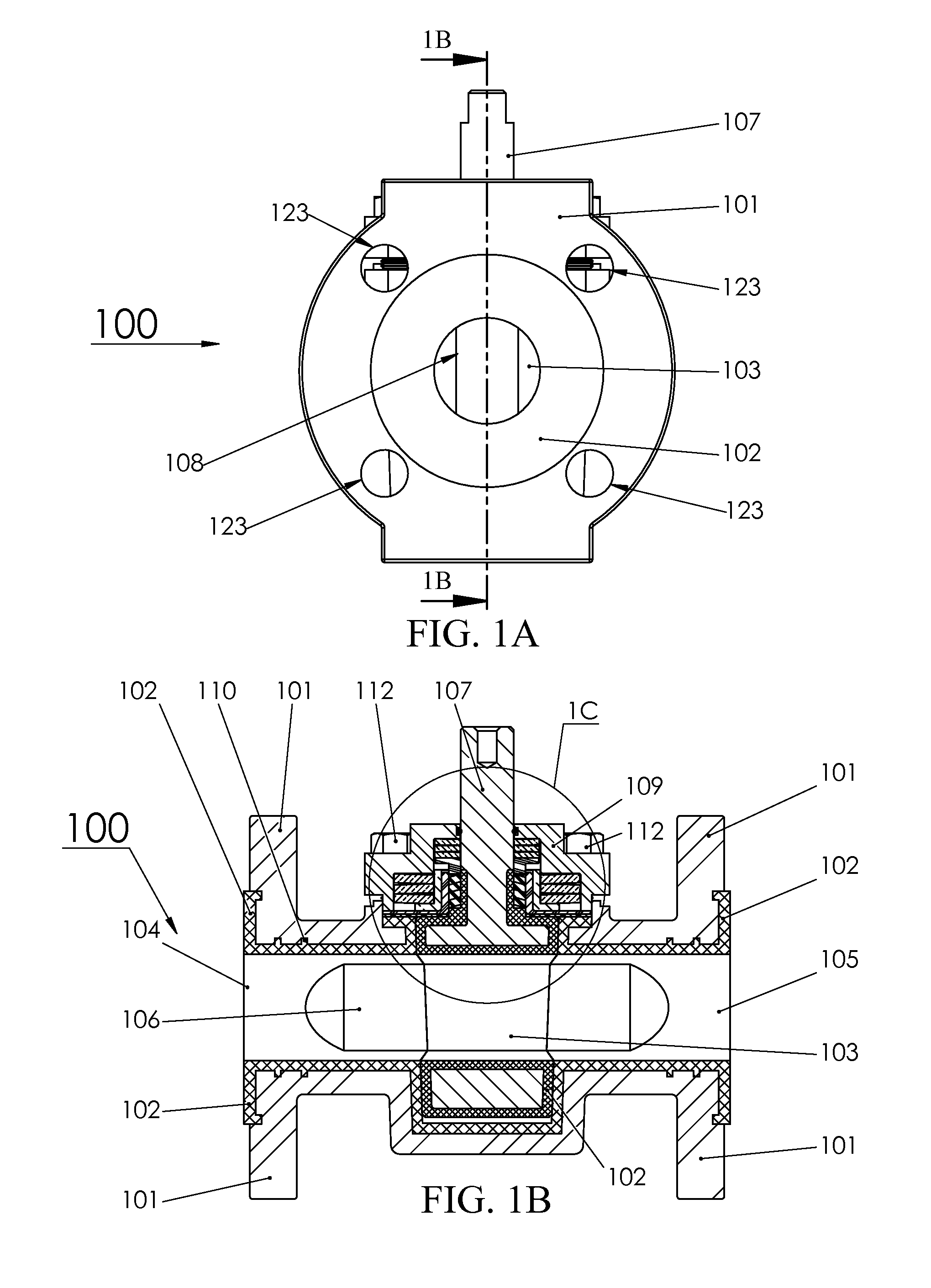

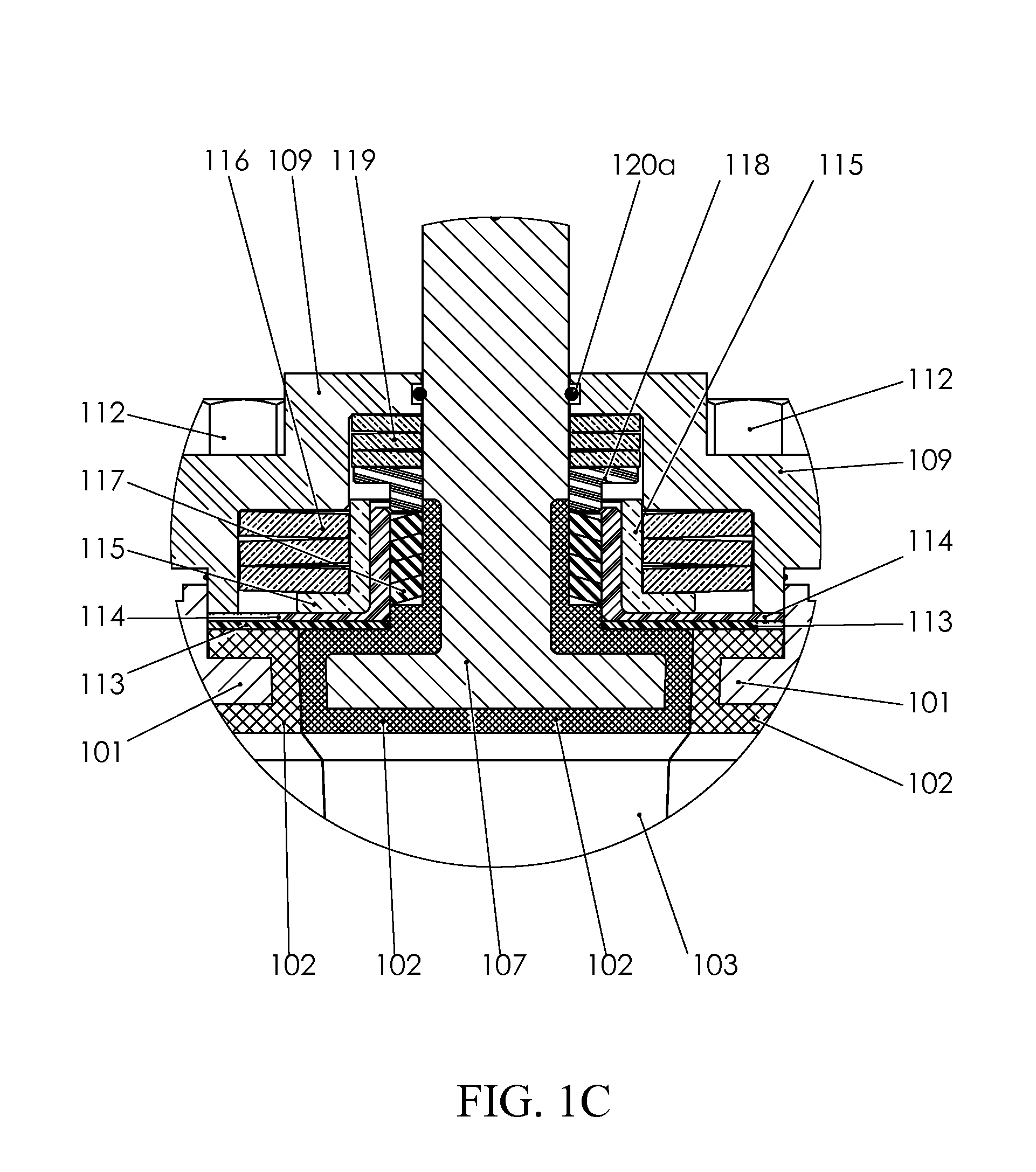

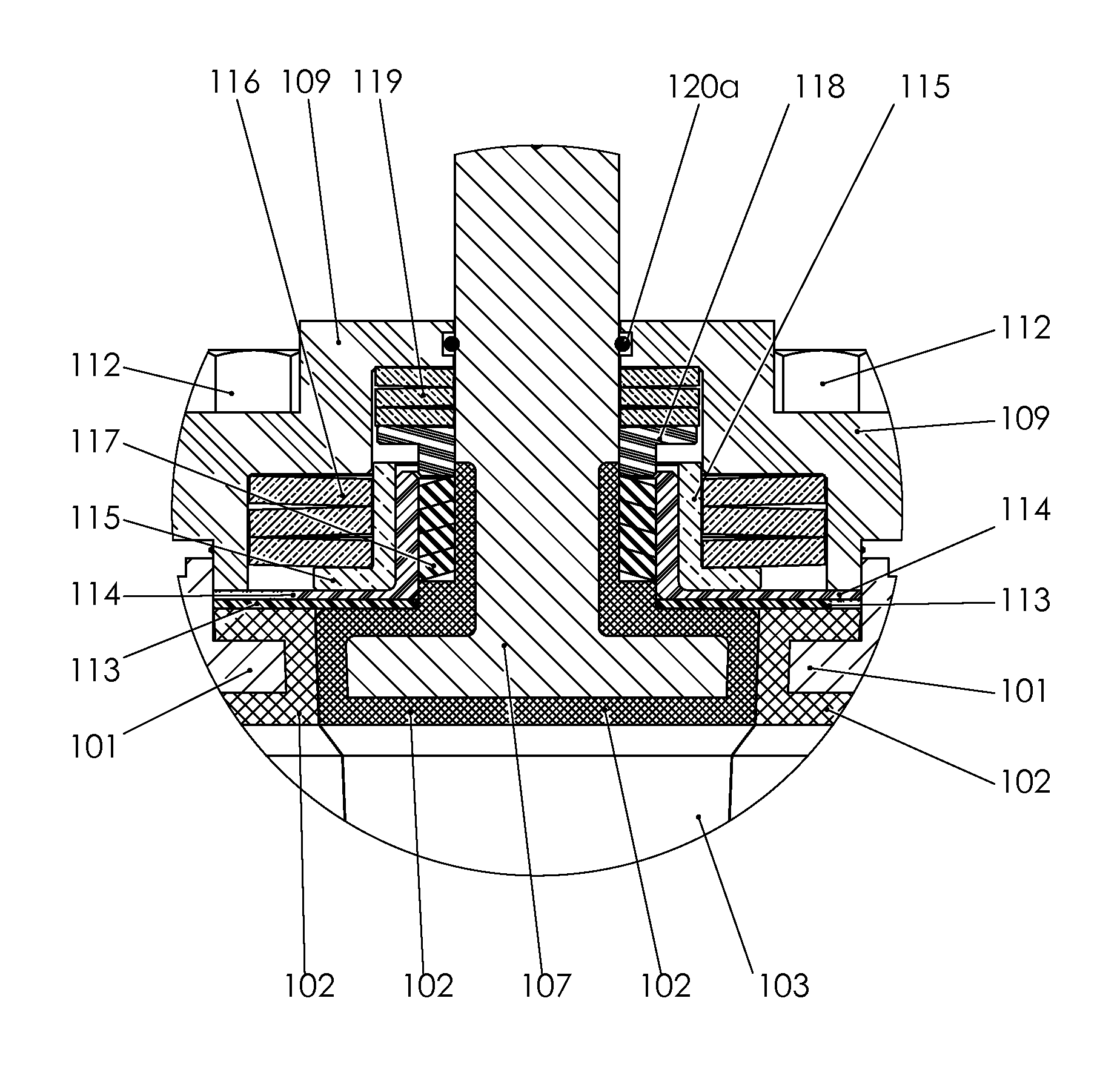

An improved and more robust plug valve and stem sealing assembly capable of preventing leakage under demanding environmental and operating conditions while also improving the reliability of the valve seal. The valve includes a body, a flow-element, a bonnet and a self-adjusting stem sealing assembly. The body has a first port and a second port with a passage configured to flow a media extending between said first port and said second port. The flow-element is positioned between the first and second port and has a stem configured to actuate the flow-element between a closed position and an open position. The bonnet may be secured to the valve body and configured to secure the flow-element and stem sealing assembly in position. The self-adjusting stem sealing assembly is positioned adjacent to the stem and is configured to prevent media leakage from the valve.

Owner:AEGIS FLOW TECH L L C

Plug valve and stem sealing assembly

ActiveUS8702056B2Improve reliabilityReduced maintenance needsSpindle sealingsPlug valvesEngineeringVALVE PORT

A plug valve and stem sealing assembly capable of preventing leakage under demanding environmental and operating conditions while also improving the reliability of the valve seal. The valve includes a body, a flow-element, a bonnet and a self-adjusting stem sealing assembly. The body has a first port and a second port with a passage configured to flow a media extending between the first port and the second port. The flow-element is positioned between the first and second port and has a stem configured to actuate the flow-element between a closed position and an open position. The bonnet may be secured to the valve body and configured to secure the flow-element and stem sealing assembly in position. The self-adjusting stem sealing assembly is positioned adjacent to the stem and is configured to prevent media leakage from the valve.

Owner:AEGIS FLOW TECH L L C

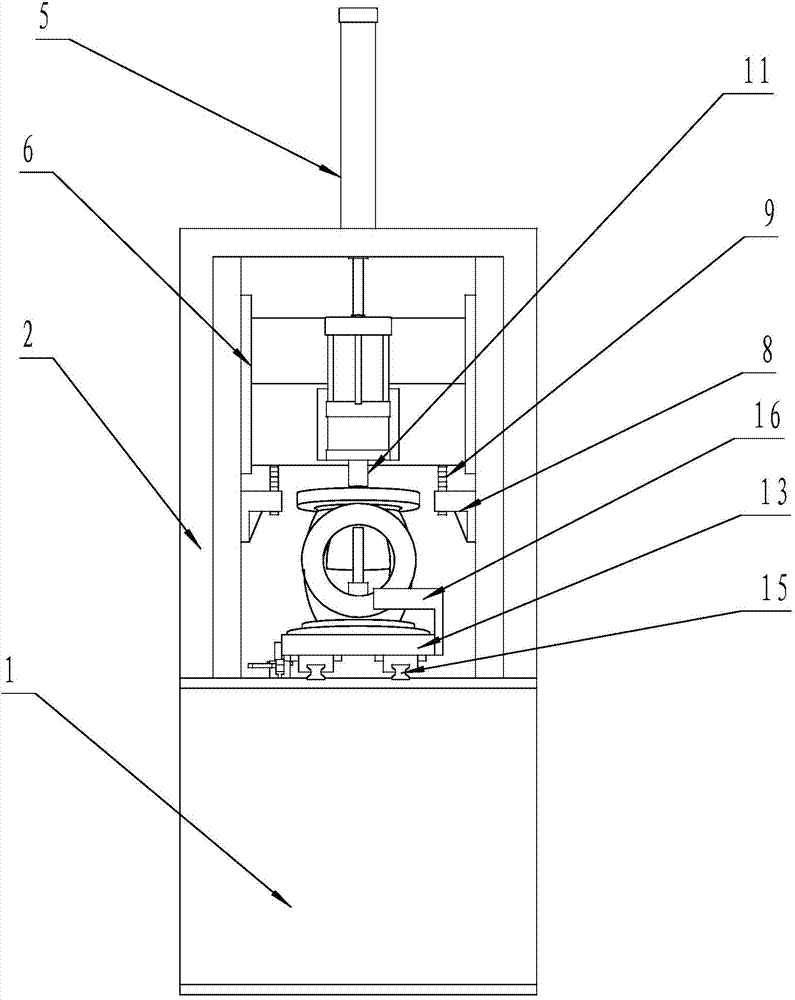

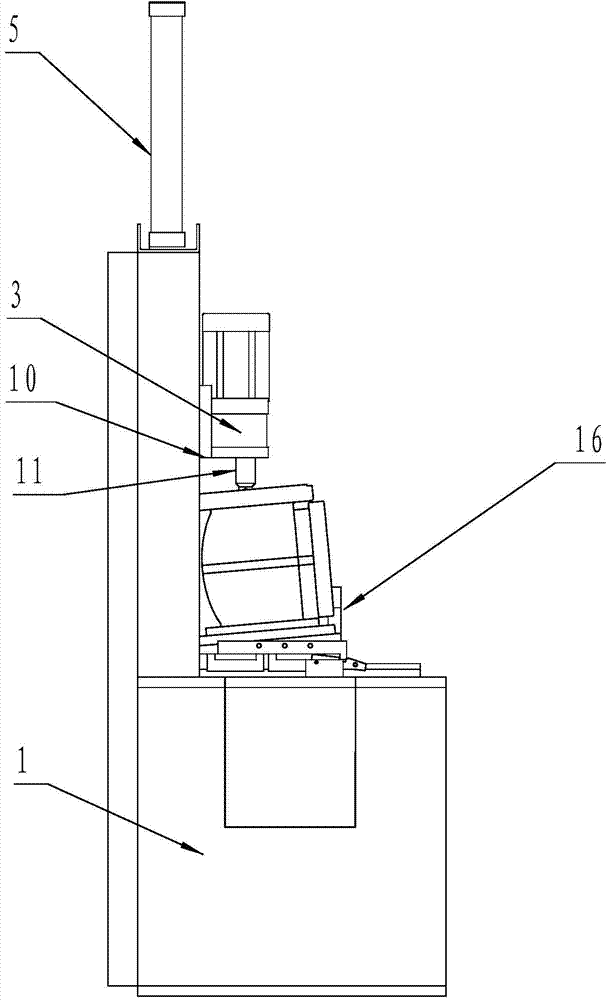

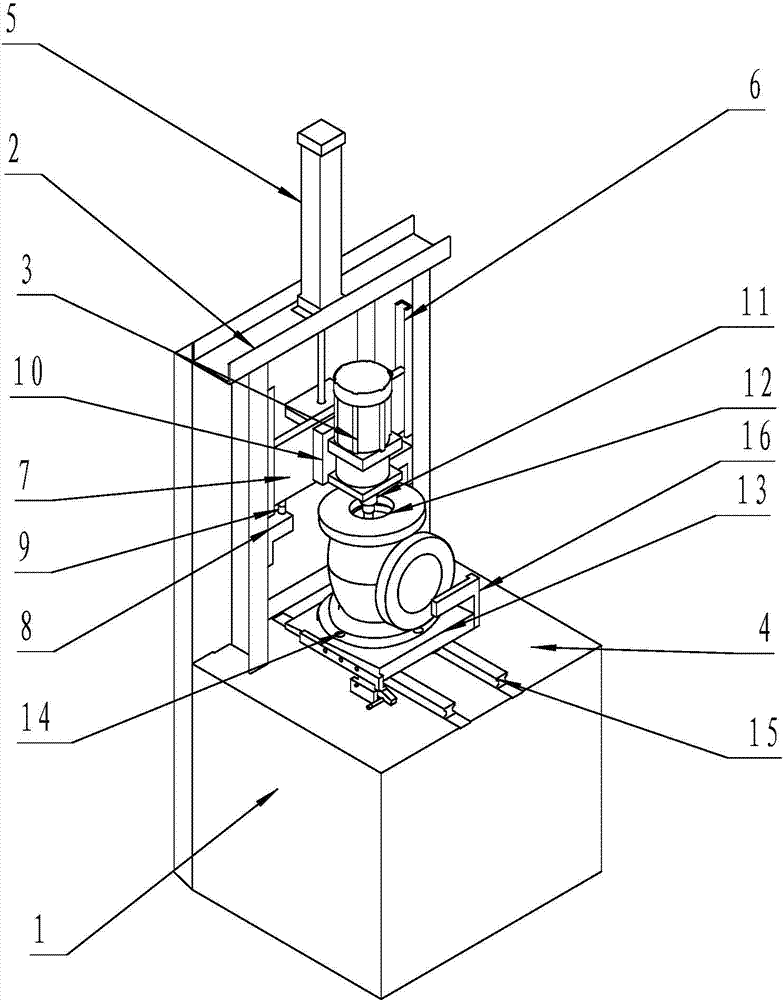

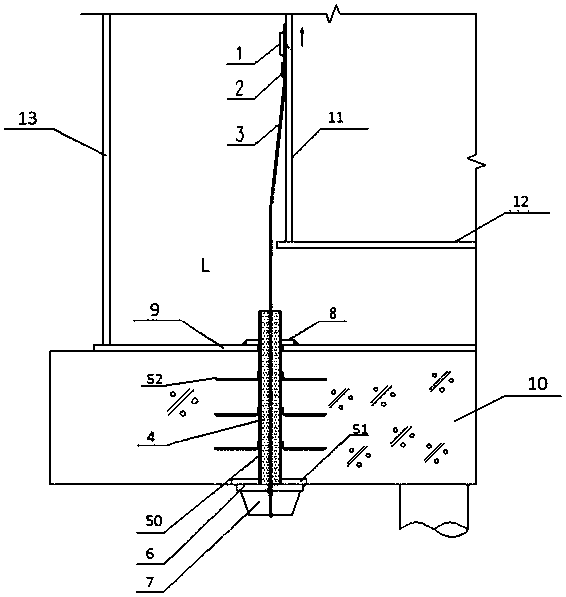

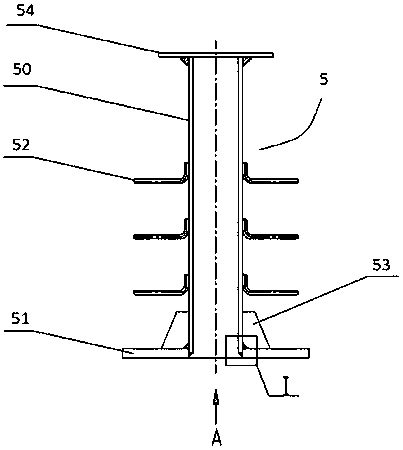

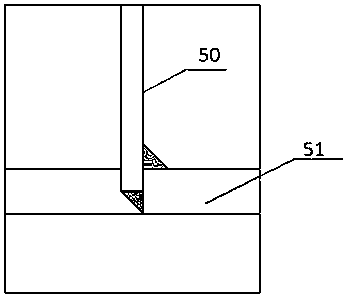

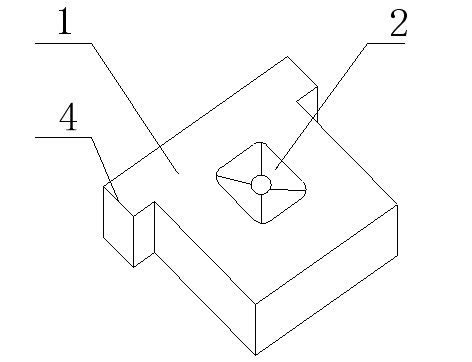

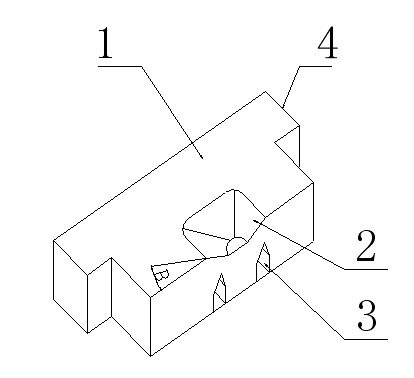

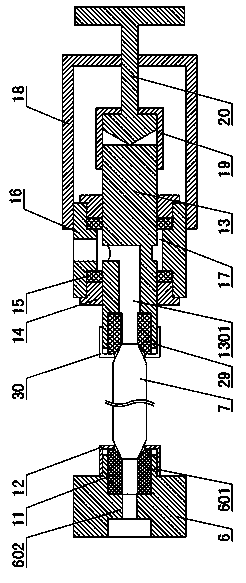

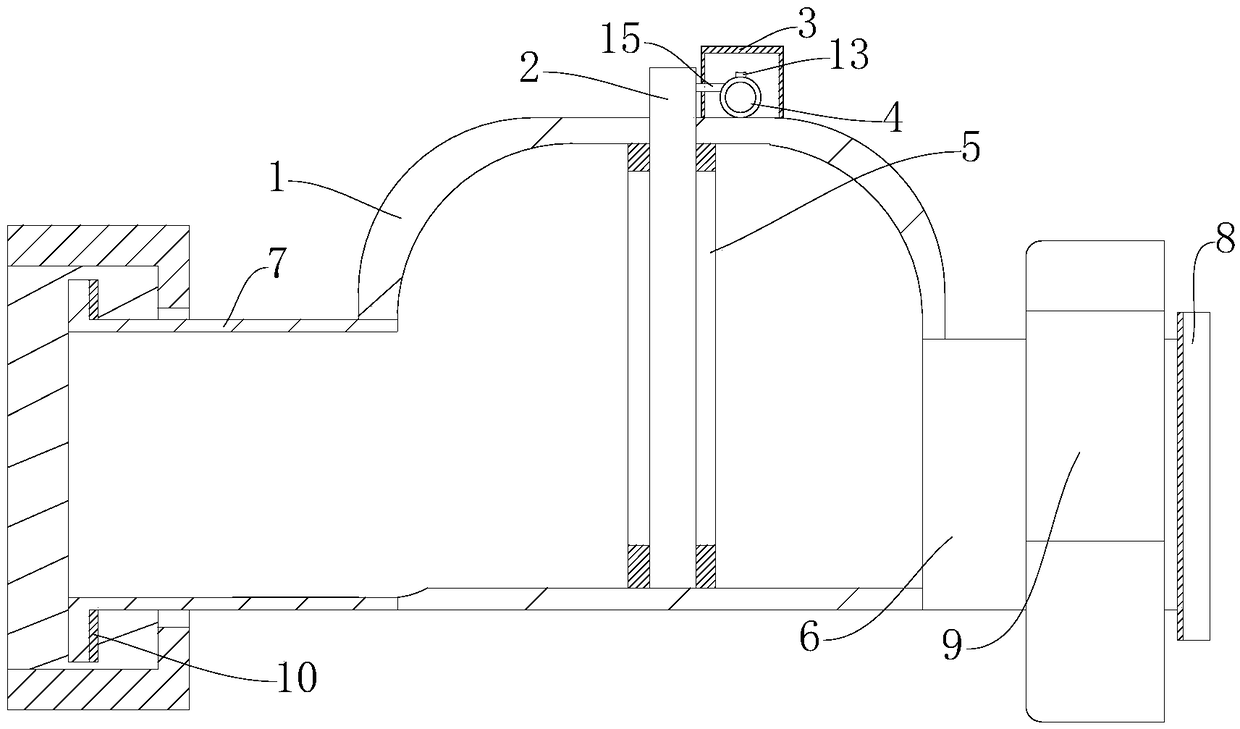

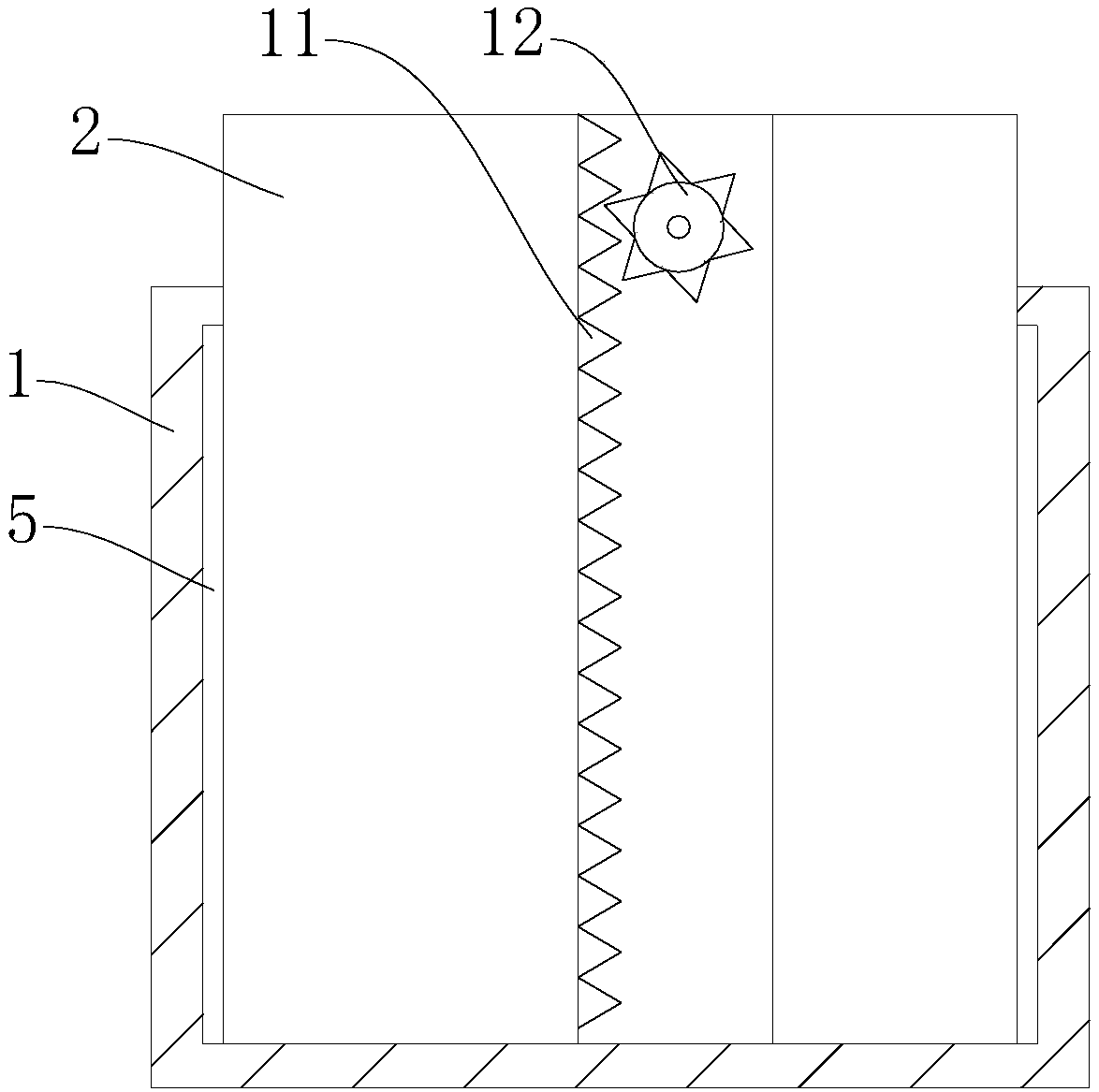

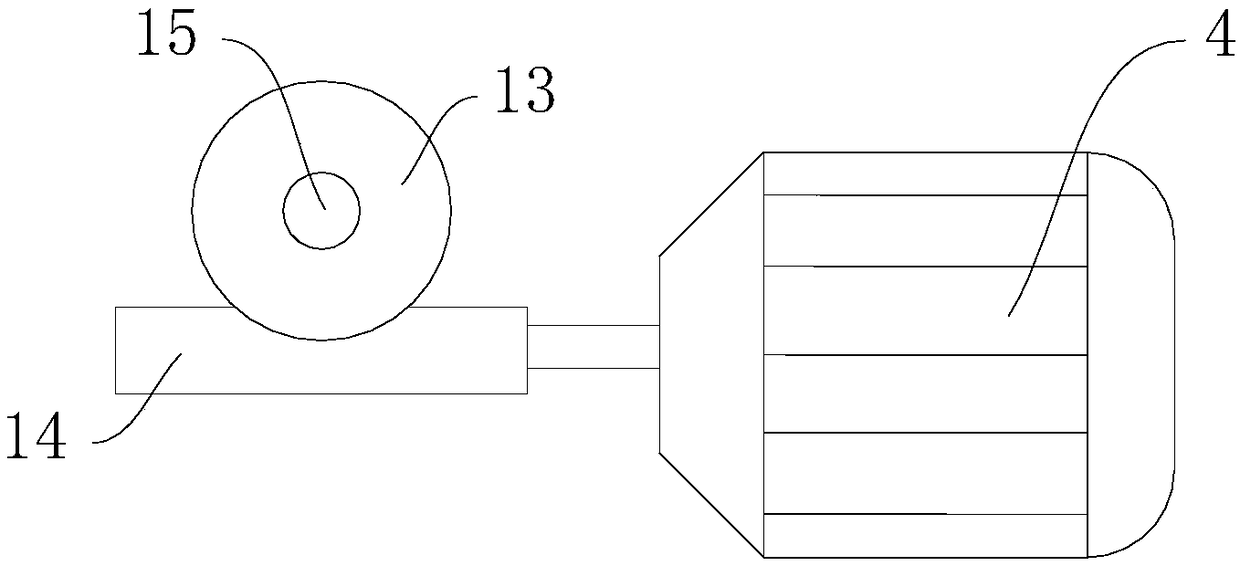

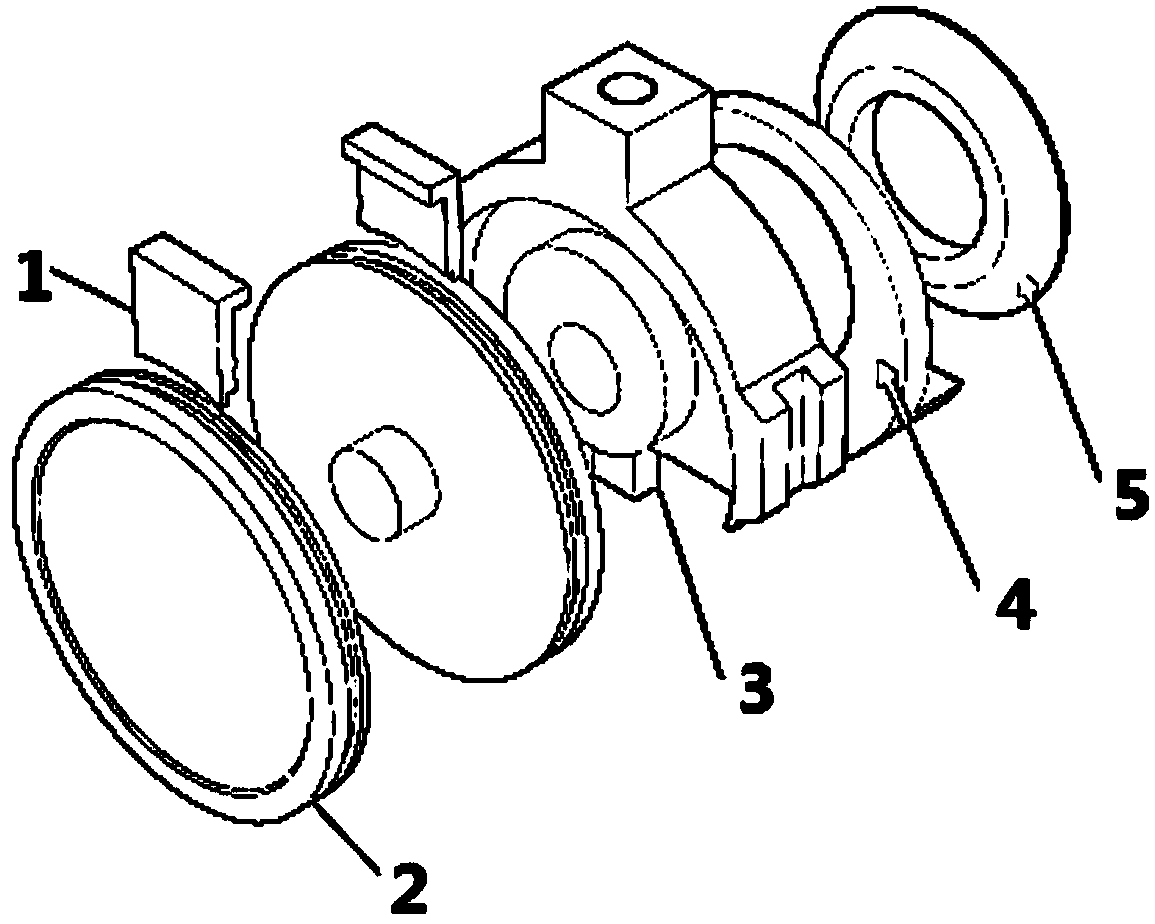

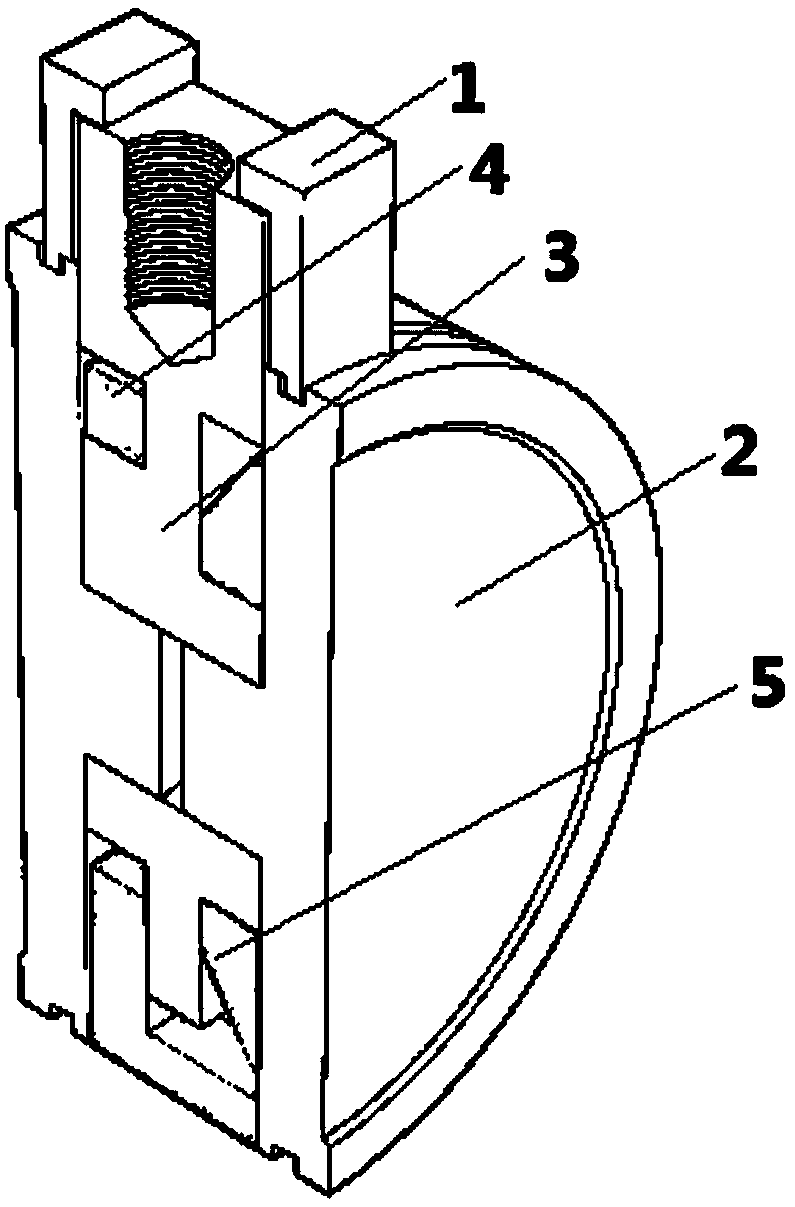

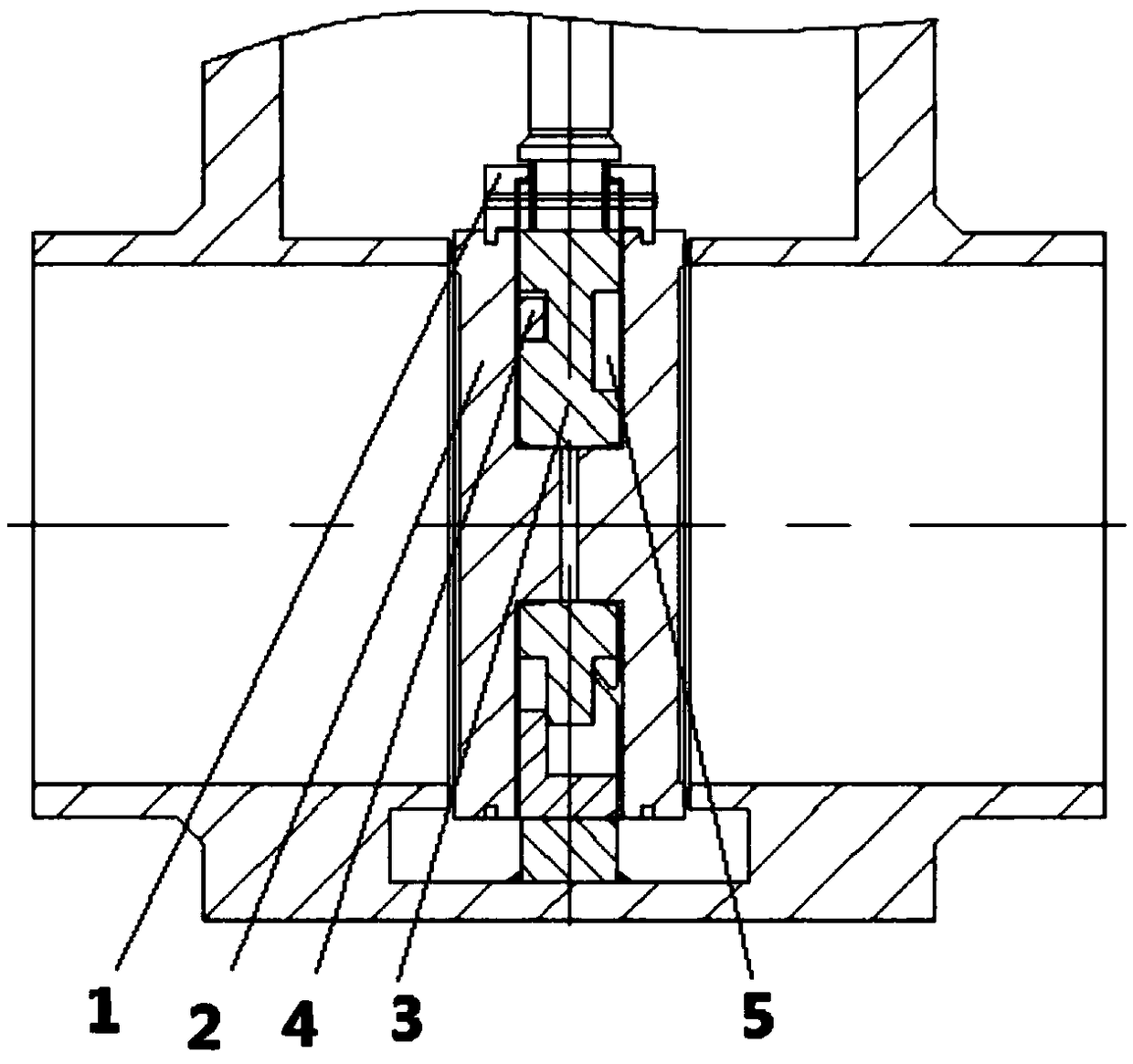

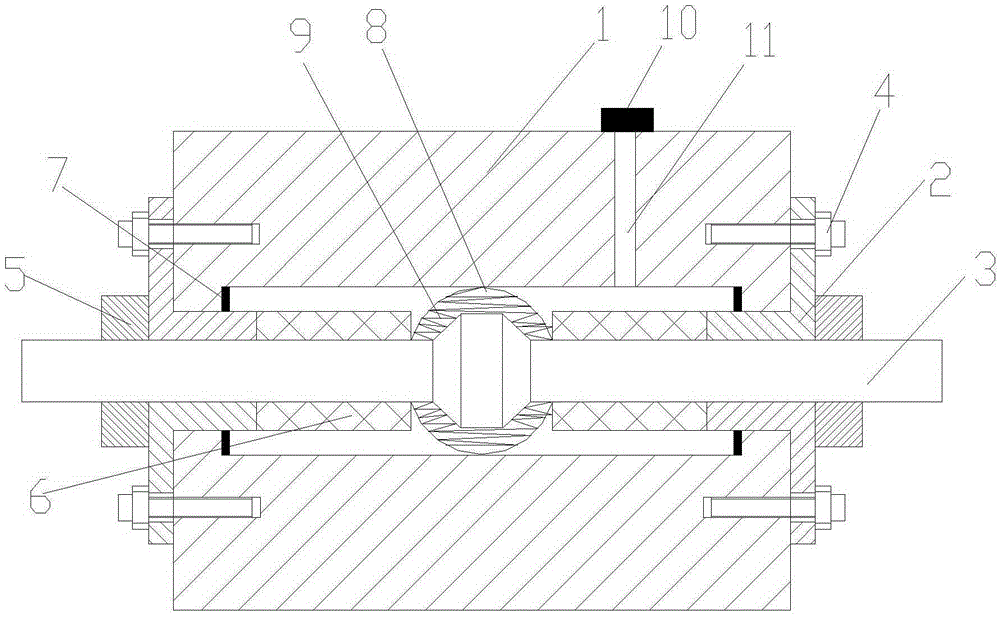

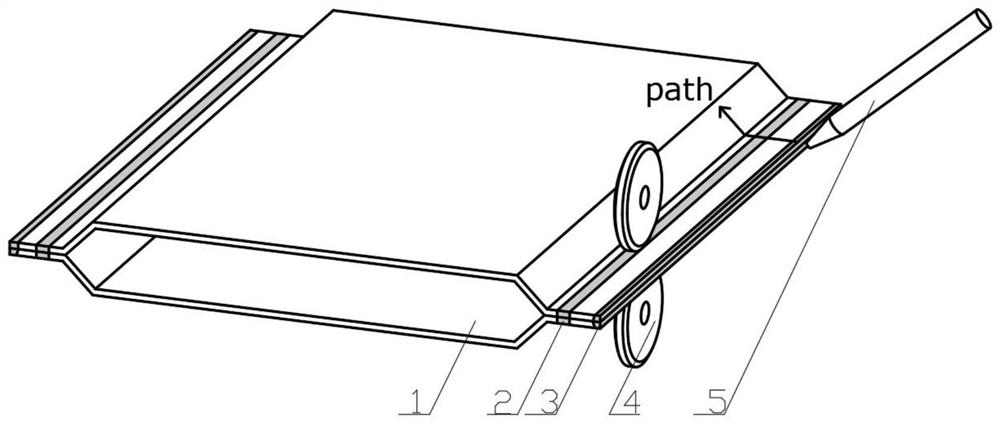

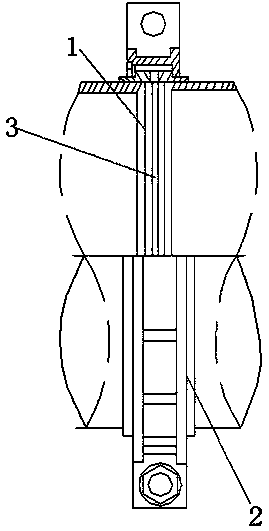

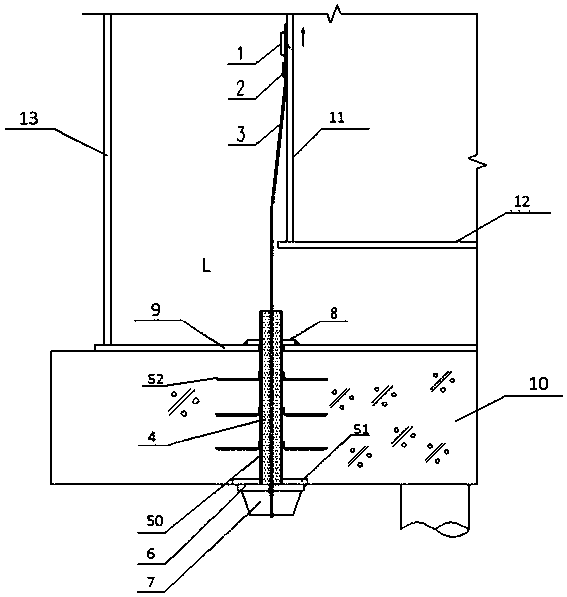

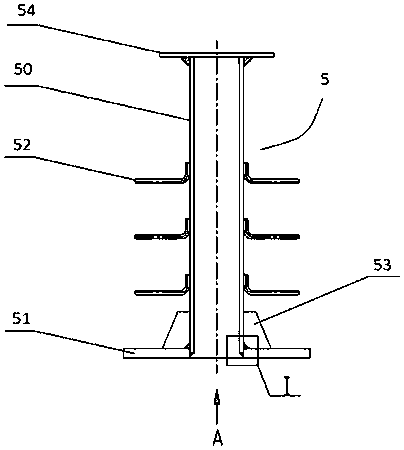

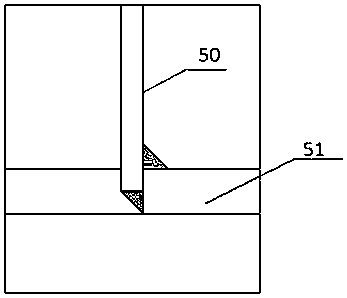

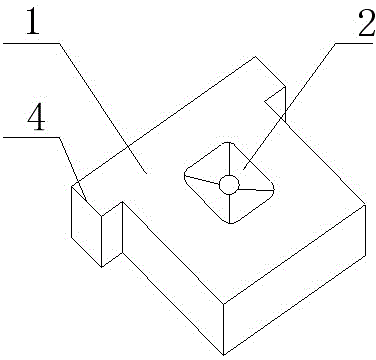

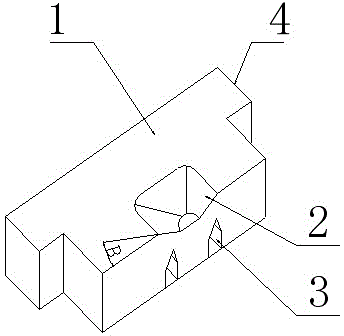

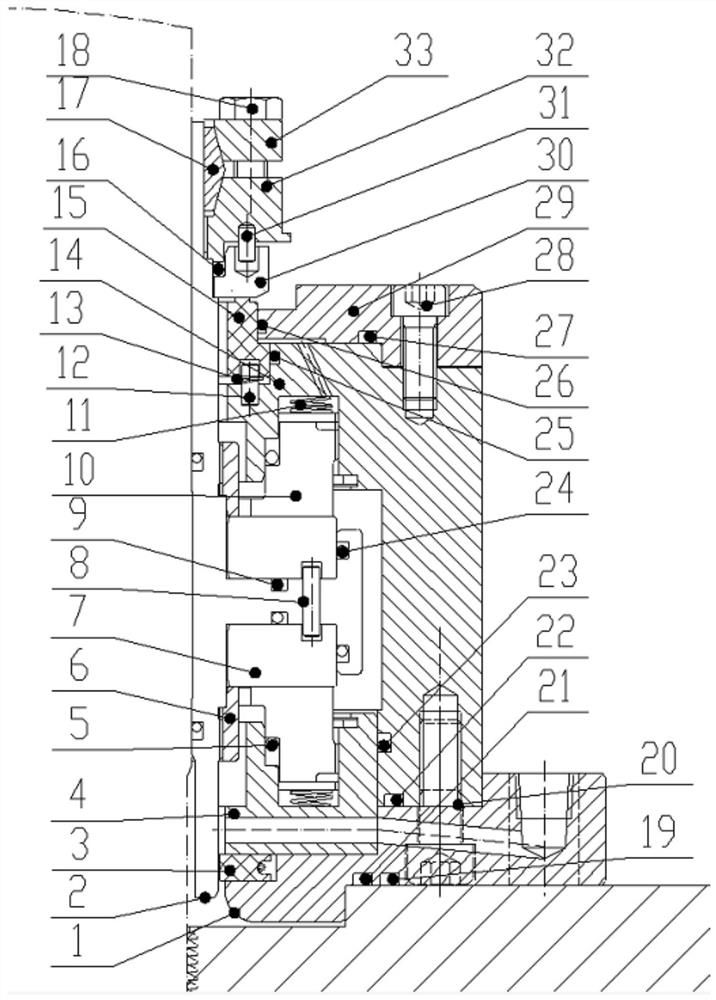

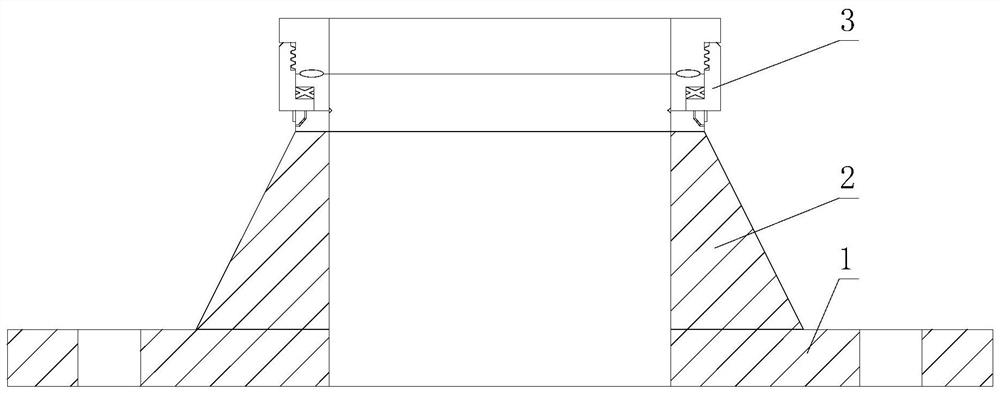

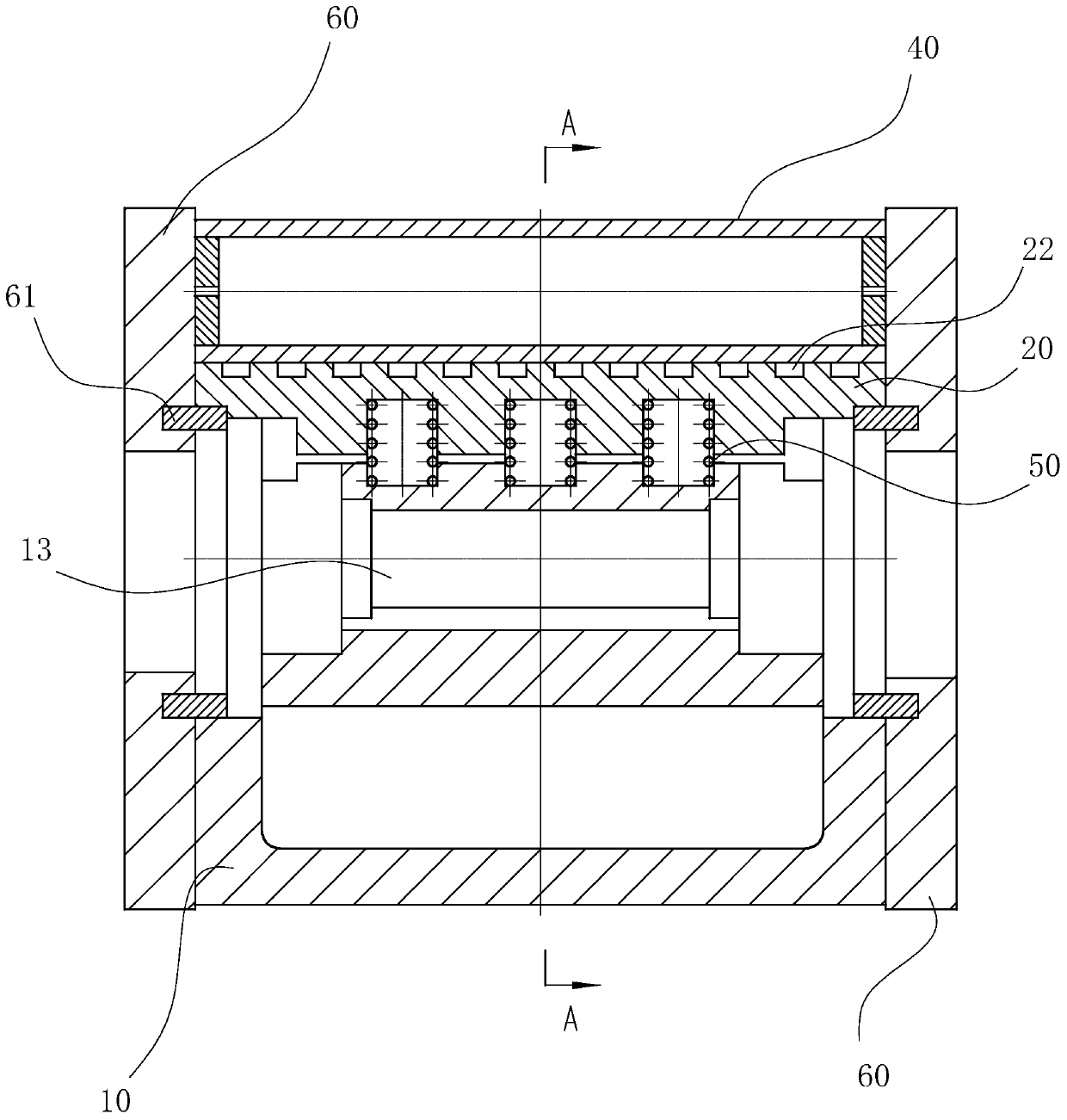

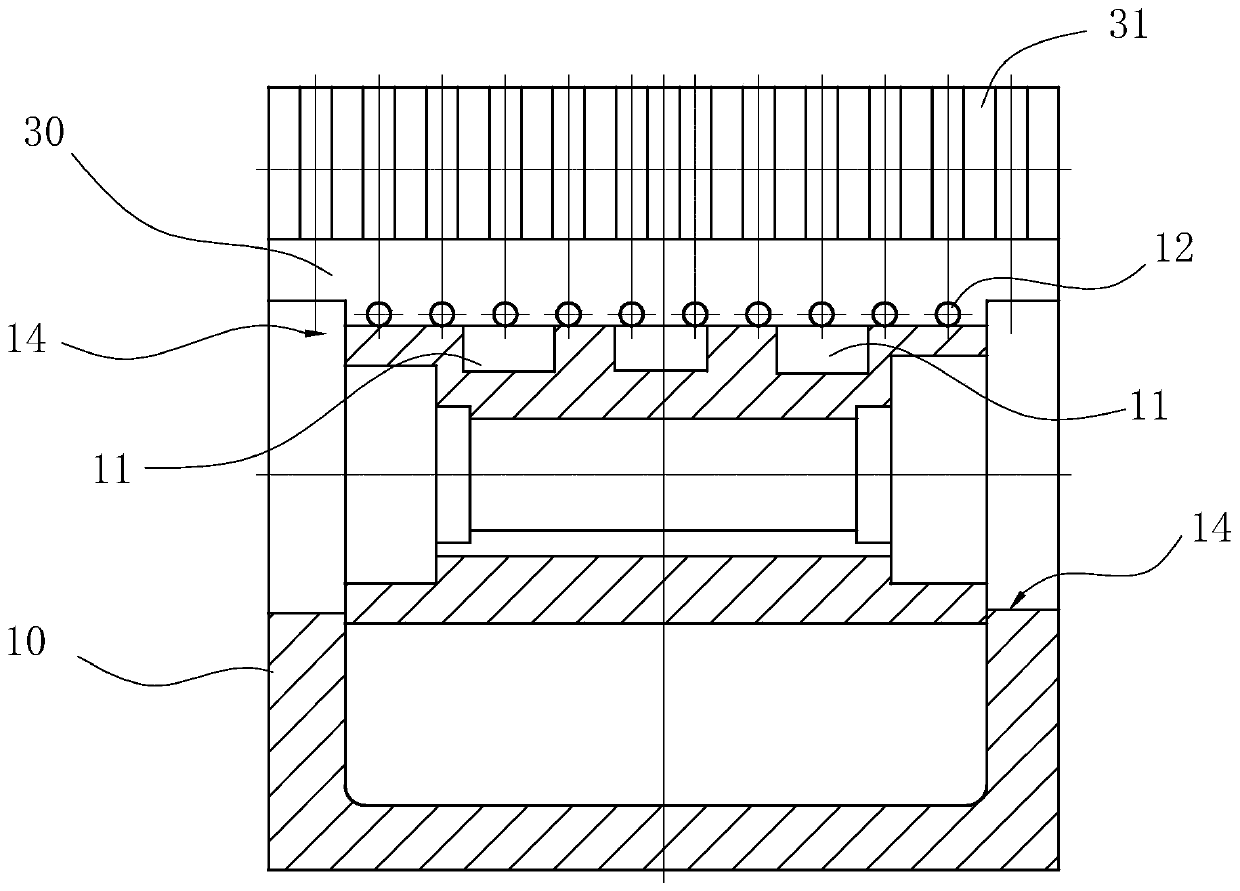

Grinding machine for hard seal copper gaskets of check valves

ActiveCN104493686AImprove grinding finenessMeet the grinding process requirementsLapping machinesReducerEngineering

The invention discloses a grinding machine for hard seal copper gaskets of check valves. The grinding machine comprises a base, a door-shaped frame, a speed reducer, a hard seal copper gasket grinding device, a lifting device of the hard seal copper gasket grinding device, a limiting device of the hard seal copper gasket grinding device, a check valve body fixing device and an electrical and pneumatic control device. The door-shaped frame is formed by vertical columns and a crossbeam, the hard seal copper gasket grinding device is mounted below the crossbeam of the door-shaped frame, and the check valve body fixing device is mounted on a platform of the base. The grinding machine for the hard seal copper gaskets of the check valves has the advantages that automatic grinding of the hard seal copper gaskets of the check valves is realized, hard seal copper gasket grinding fineness is improved, requirements of hard seal copper gasket grinding process are met, slight leakage of media in use of the hard seal copper gaskets for sealing is prevented, and operation efficiency in grinding of the hard seal copper gaskets is improved.

Owner:JINAN MEIDE CASTING CO LTD

Aseismic structure in double-shell low-temperature in-tank tank

ActiveCN108861170AAvoid the problem of low temperature damageAvoid lift-off damageLarge containersStructural engineering

The invention provides an aseismic structure in a double-shell low-temperature in-tank tank. The aseismic structure comprises an anchor belt box, a cover body and an anchor belt, wherein the anchor belt box is arranged in a bearing table foundation, the top end is exposed out of the upper surface of the bearing table foundation and penetrates through an outer tank base plate to be in sealed welding to the outer tank base plate, the cover body is exposed out of the lower surface of the bearing table foundation and seals the bottom end of the anchor belt box, the lower end of the anchor belt penetrates the anchor belt box to be connected with the cover body, and the upper end of the anchor belt is movably connected with an inner tank wall. According to the aseismic structure, the anchor beltpenetrates the anchor belt box in the concrete bearing table foundation to be connected with the exposed cover body, the anchor belt is not in contact with the anchor belt box and is not in contact with the outer tank base plate, and the problem of low-temperature damage of the outer tank and the bearing table foundation due to the fact that cold of a low-temperature inner tank is transmitted toan outer tank and the bearing table foundation is solved; tearing force damage caused by the anchor belt to the outer tank base plate during an earthquake is avoided; the inner tank wall is movably connected to the upper end of the anchor belt, additional tension generated by the anchor belt to the inner tank wall can be avoided, the low-temperature inner tank is fixed during the earthquake, the earthquake force of a tank body is directly transmitted to a pressure bearing platform, and lift-off damage is prevented from being generated on the low-temperature inner tank during the earthquake.

Owner:SINOPEC ENG +1

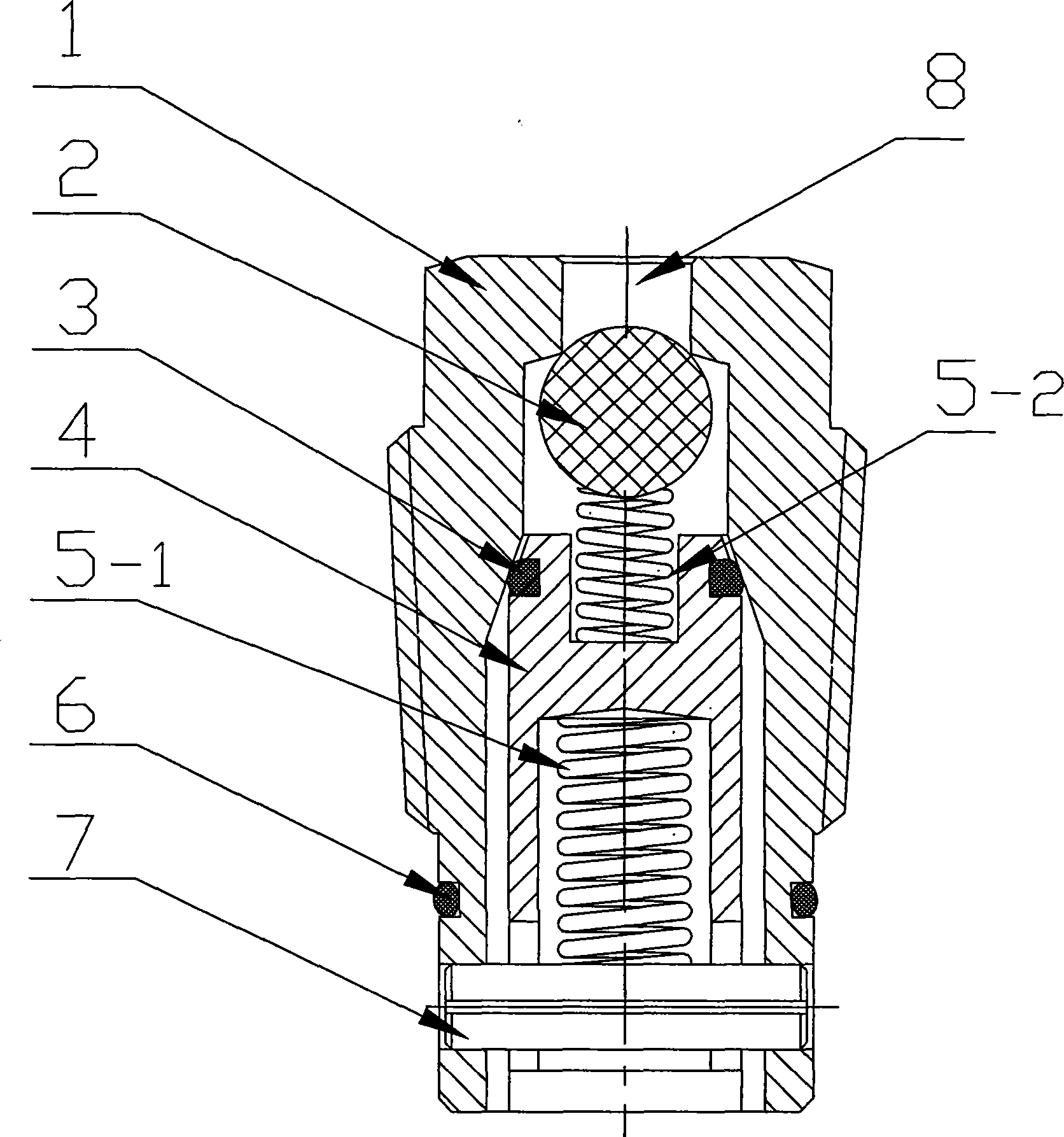

Double sealings high-pressure grease pouring valve

ActiveCN101178150APrevent media leakageGood sealing performanceDistribution equipmentInternal cavityEngineering

The invention provides a dual sealing high pressure grease filling valve. The upper part of a valve tip is provided with a movable hard sealing ball; the movable hard sealing ball and a grease filling hole in an internal cavity of the valve body generate a ball-shaped linear sealing; the taper of the valve tip is provide with an elastic sealing ring which is hermetically contacted with the taper in the grease filling hole of the internal cavity of the valve body; the movable hard sealing ball and the grease filing hole in the internal cavity of the valve body generate the linear sealing closing and generate a sealing line; another sealing line is generated by the contact between the taper in the grease filling hole of the valve body and the rebounded elastic sealing ring on the taper of the valve tip. In the sealing structure of the invention, the interior of the valve body adopts the dual sealing between the movable hard sealing ball and the taper elastic sealing ring; when the sealing abrasion appears to the abrasion, the valve body bevel and the elastic sealing ring can take a compensation function, thus reaching the aim of preventing the medium leakage, and having good sealing performance and long service life, etc.

Owner:金星阀门有限公司

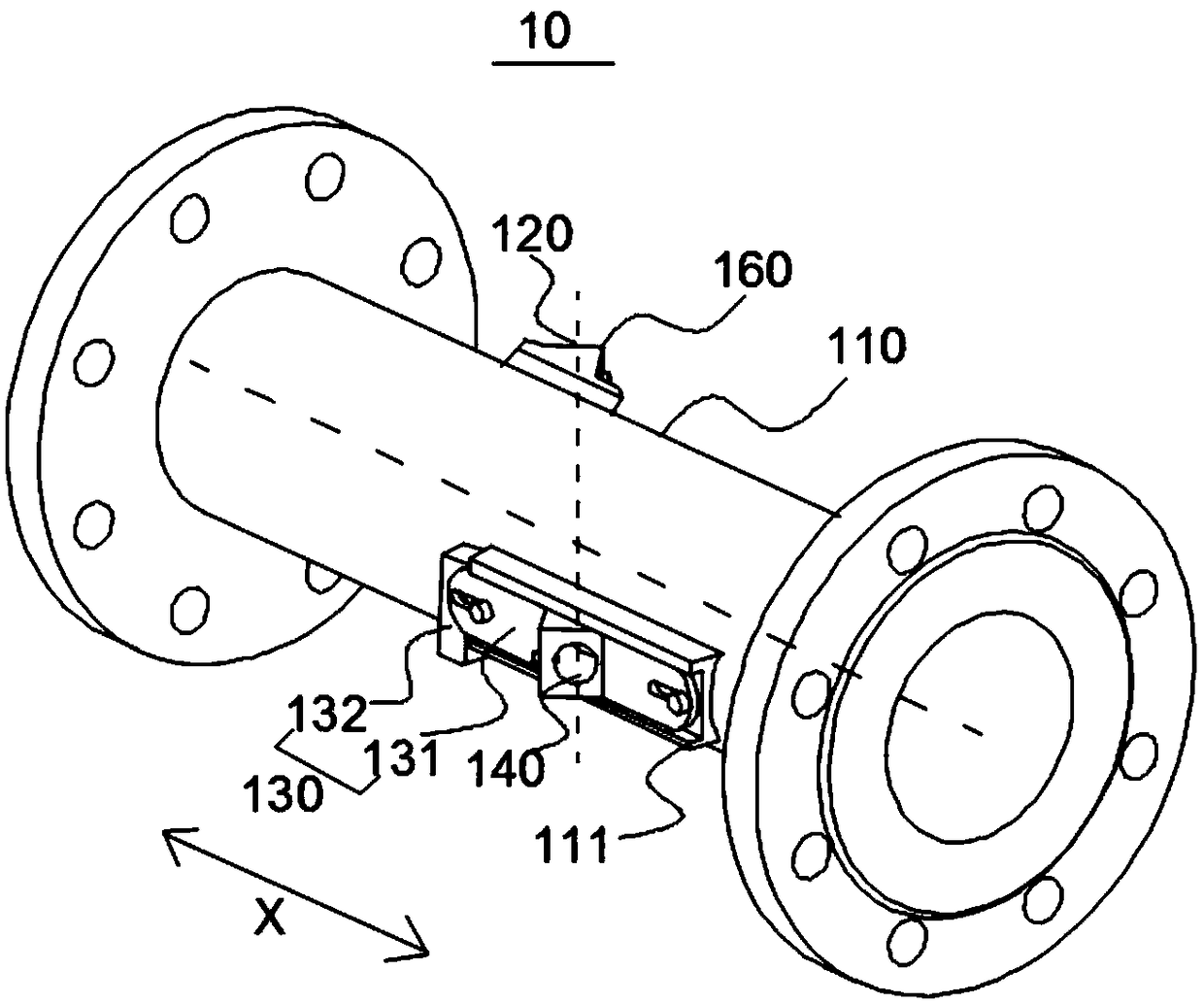

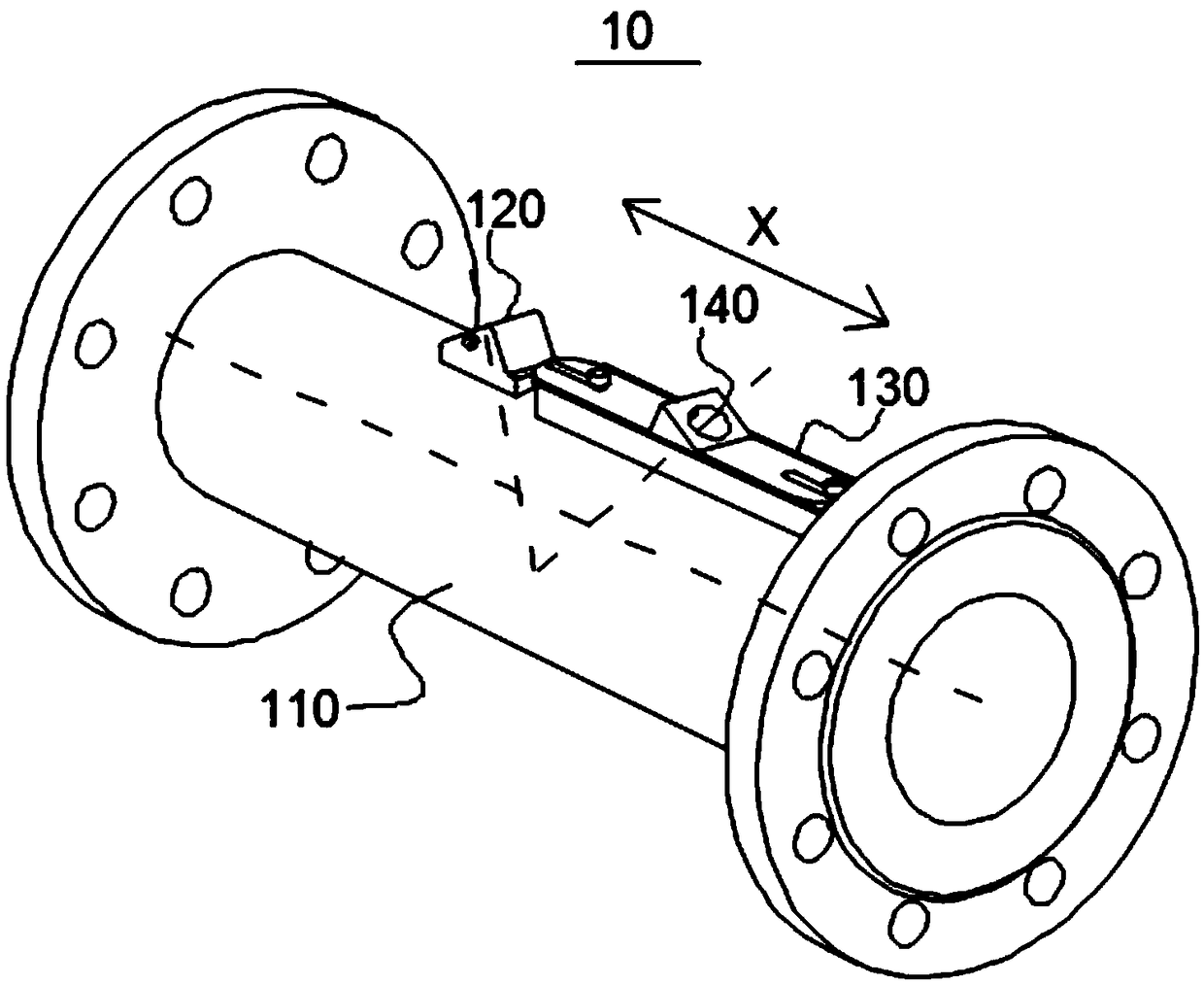

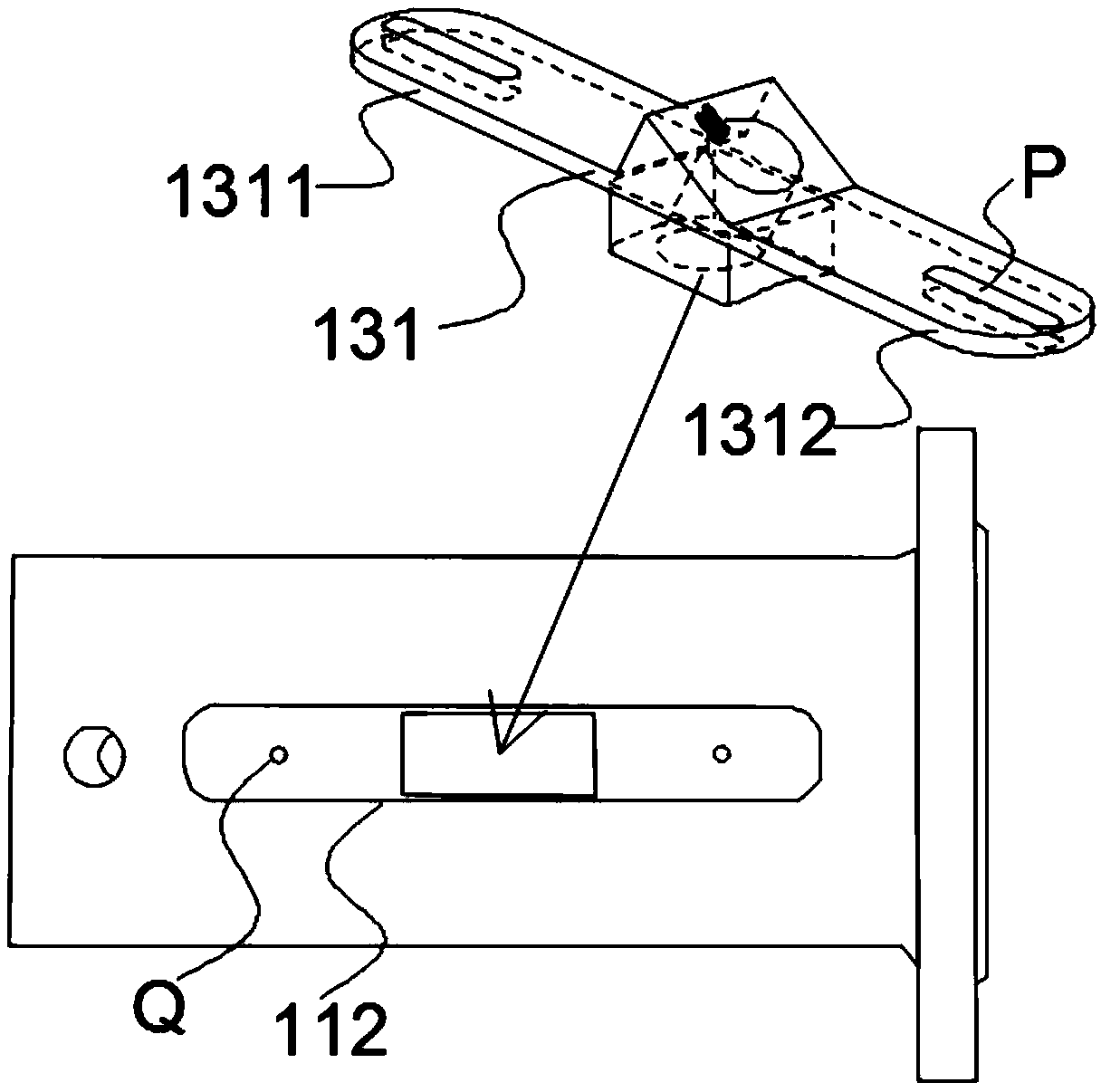

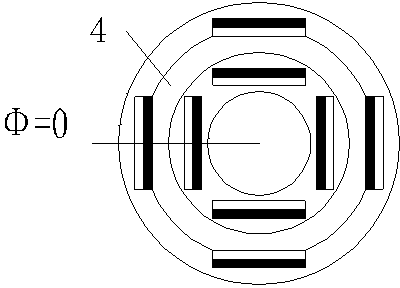

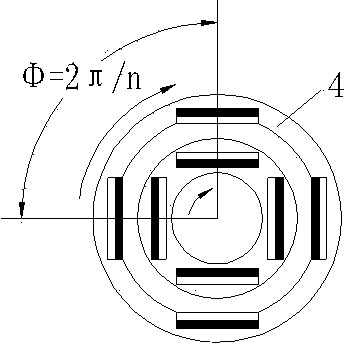

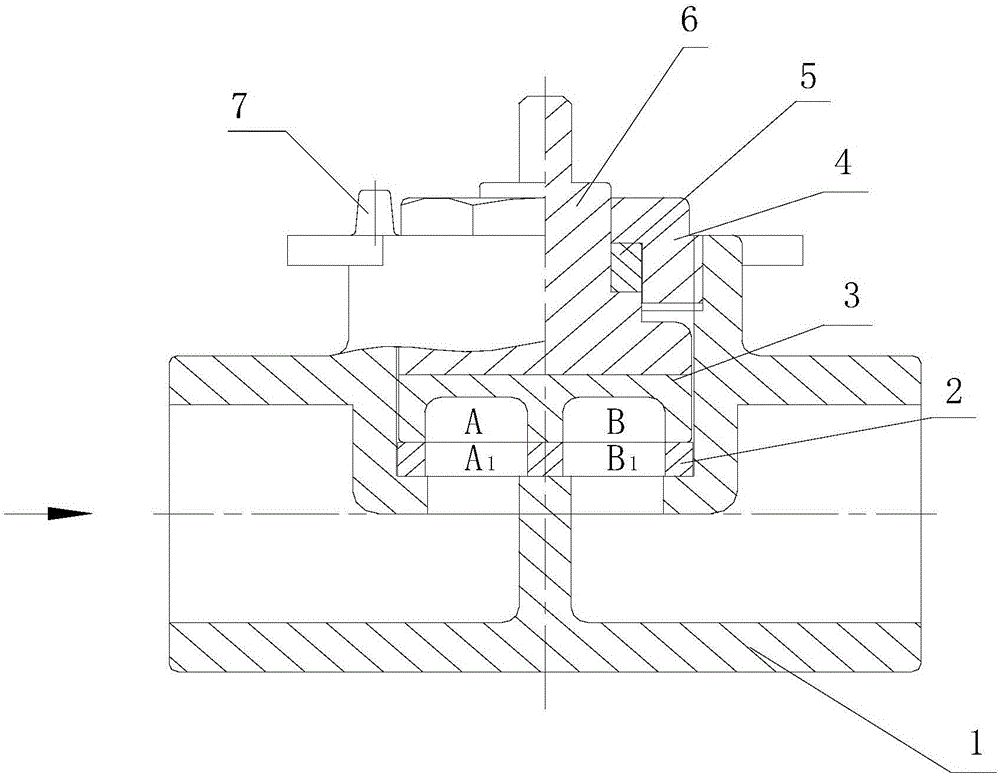

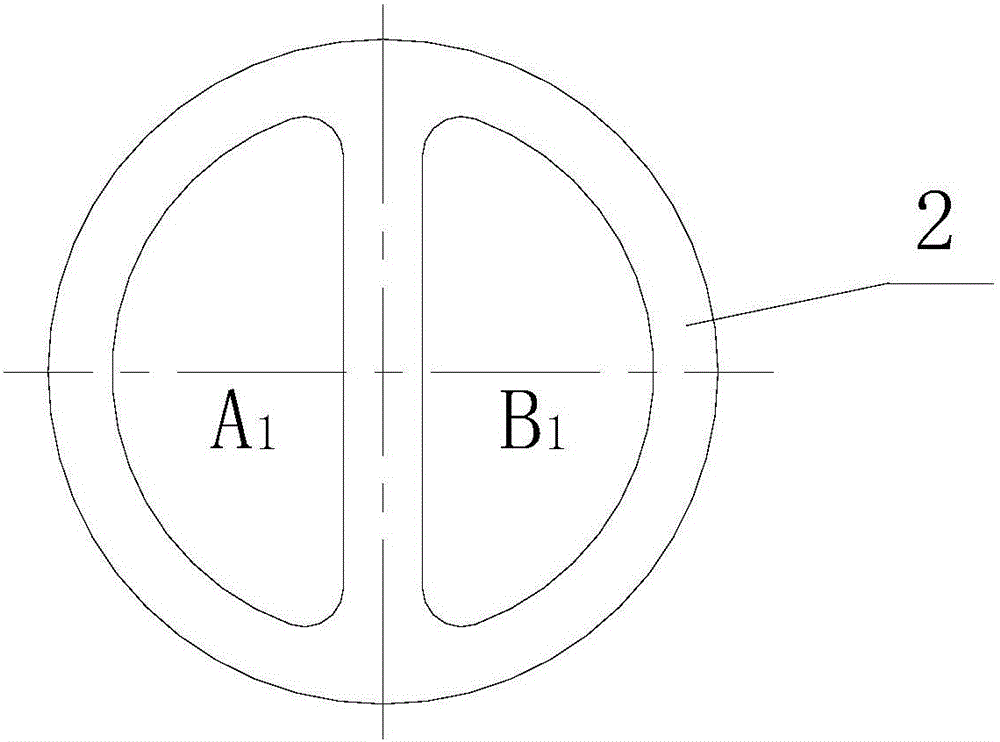

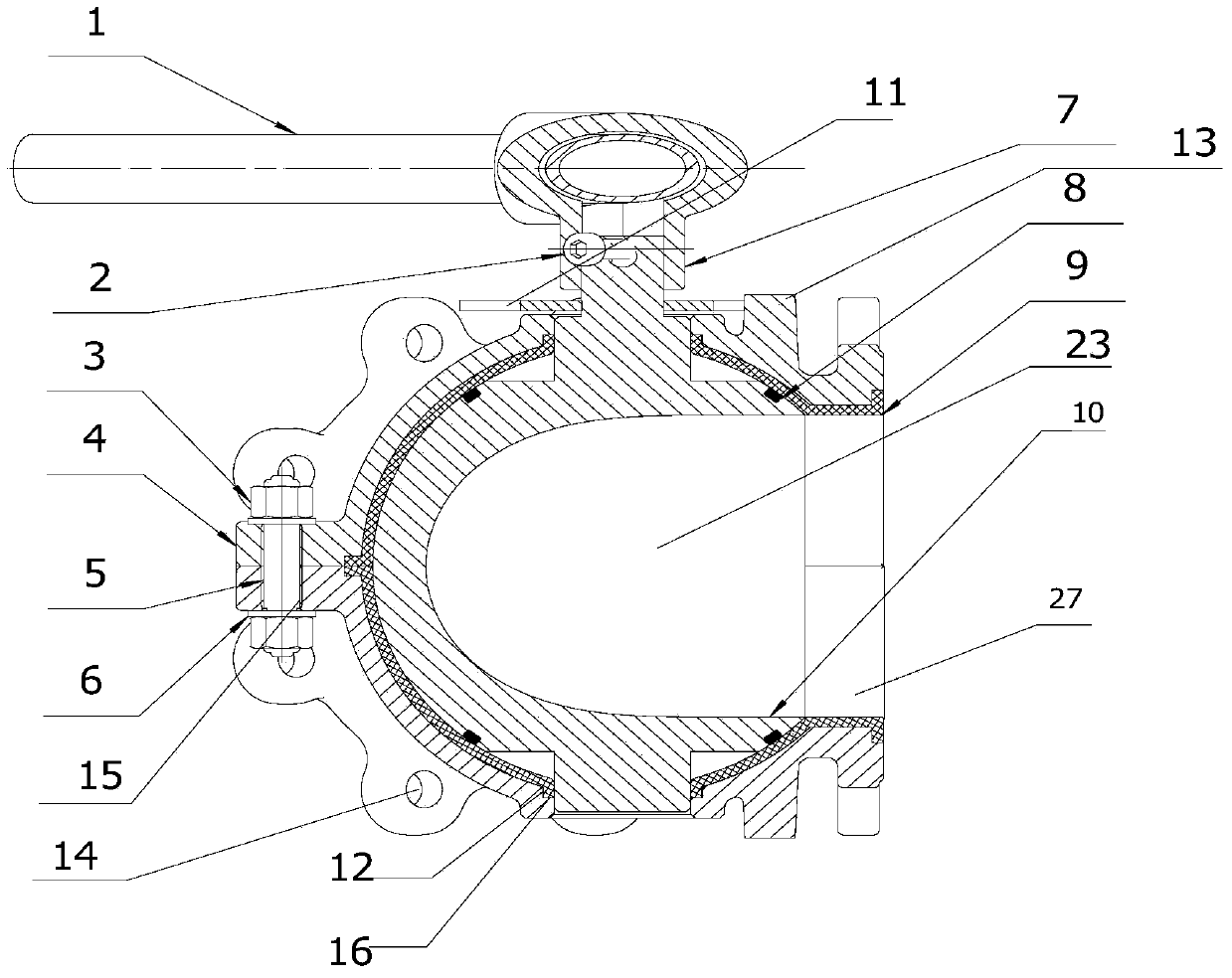

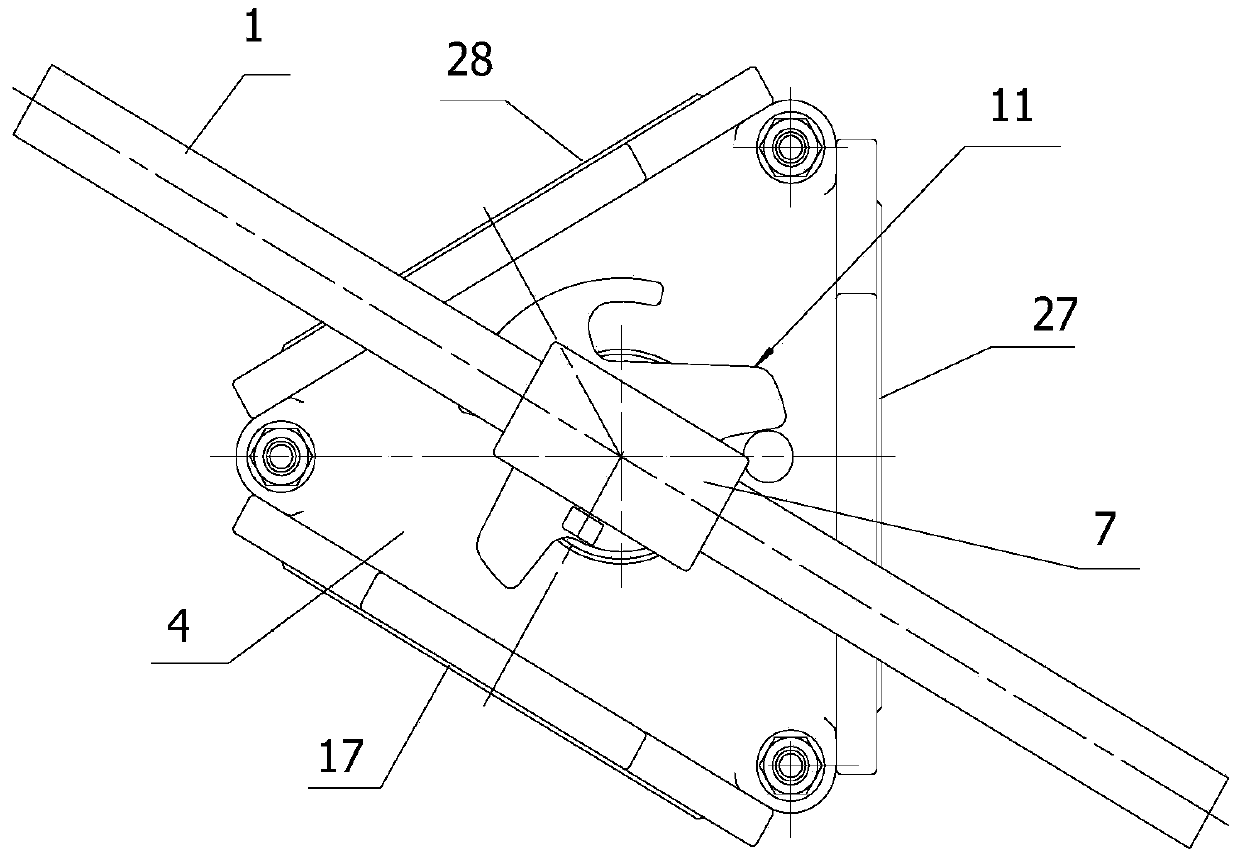

Ultrasound flowmeter and method for regulating transducers

PendingCN109341794AAvoid the problem of ultrasonic signal weakeningOptimize the installation methodVolume/mass flow measurementTransducerEngineering

The embodiment of the invention provides an ultrasound flowmeter and a method for regulating transducers. In the embodiment, the ultrasound flowmeter includes a flowmeter housing, a first transducer mounted on the flowmeter housing, a regulating mechanism mounted on the flowmeter housing, and a second transducer mounted on the regulating mechanism for receiving ultrasonic wave emitted by the firsttransducer; the regulating mechanism in a working state drives the second transducer to move in a first preset direction. In order to solve the problem of the weak intensity , caused by signal excursion, of the received ultrasonic signal, the regulating mechanism can drive the second transducer to move in the first preset direction so as to receive the strong ultrasonic signal in time, and the measurement accuracy is thus improved.

Owner:南京光声超构材料研究院有限公司 +2

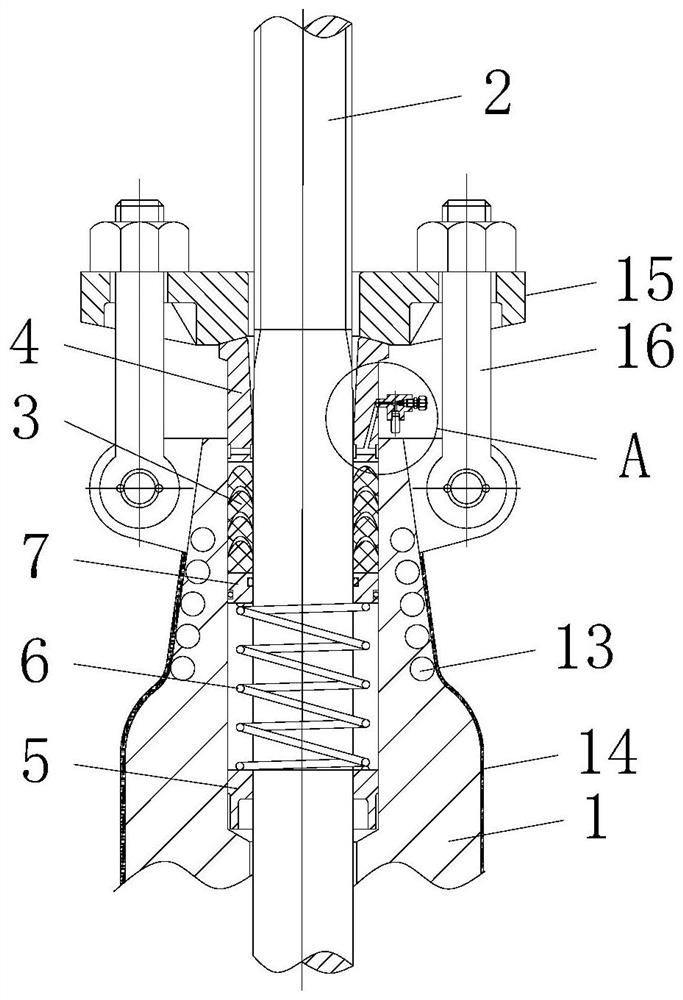

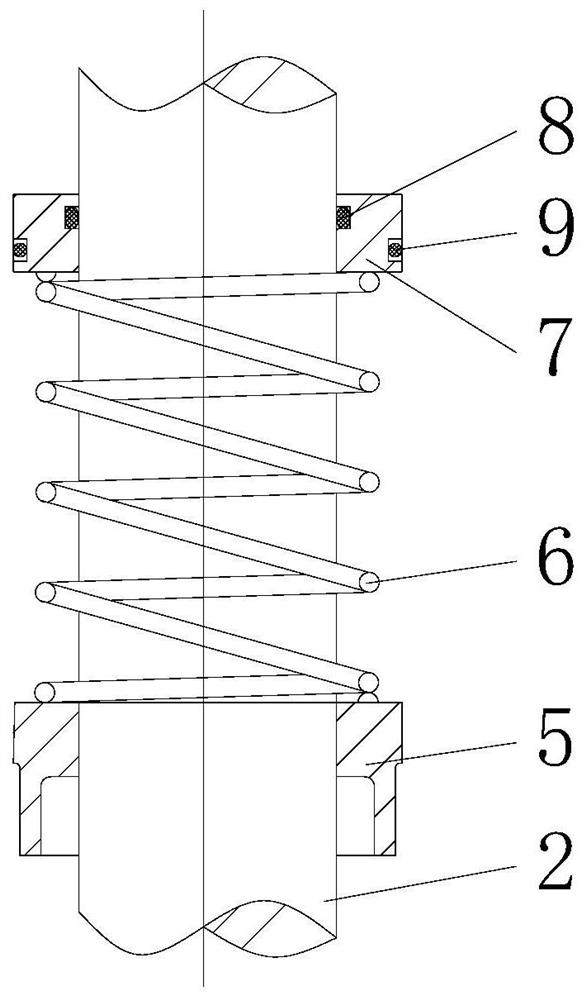

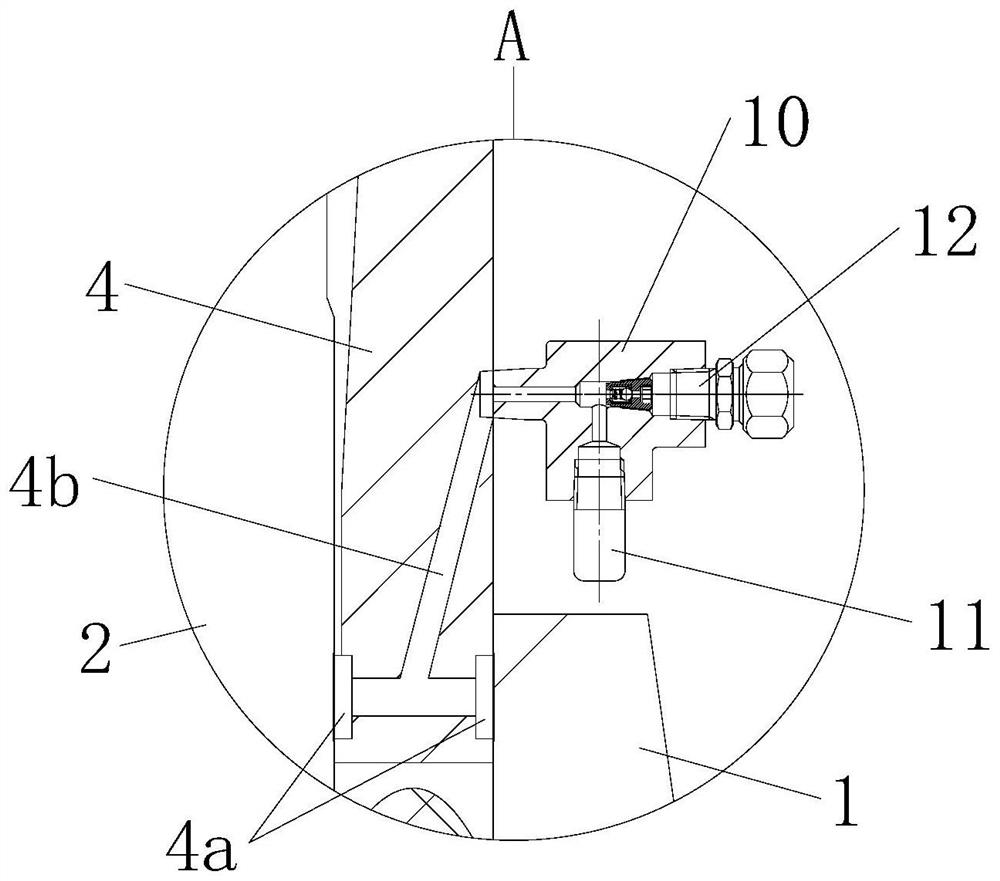

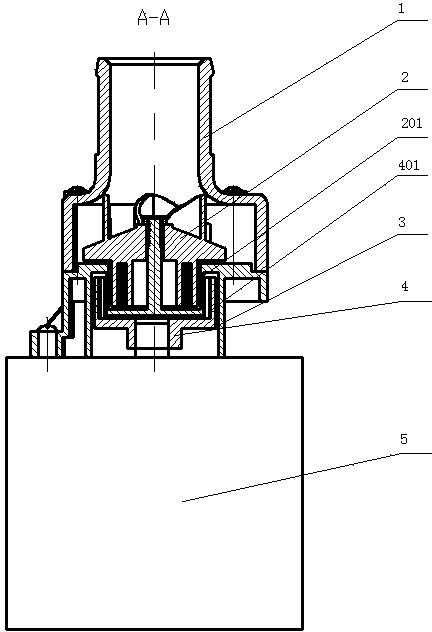

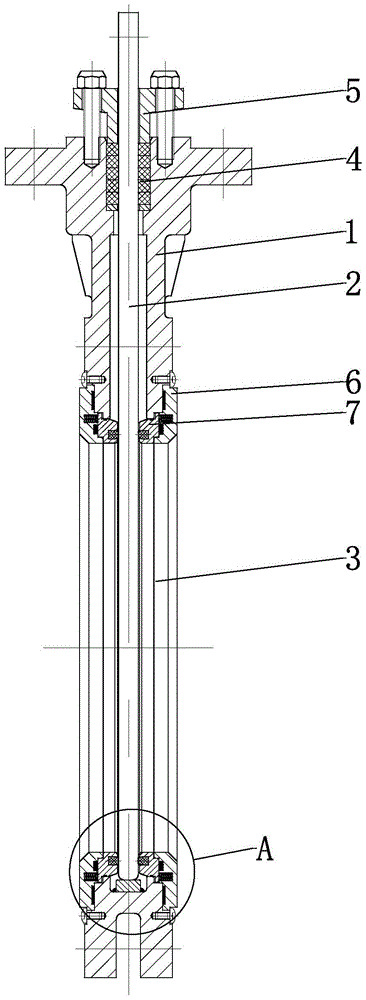

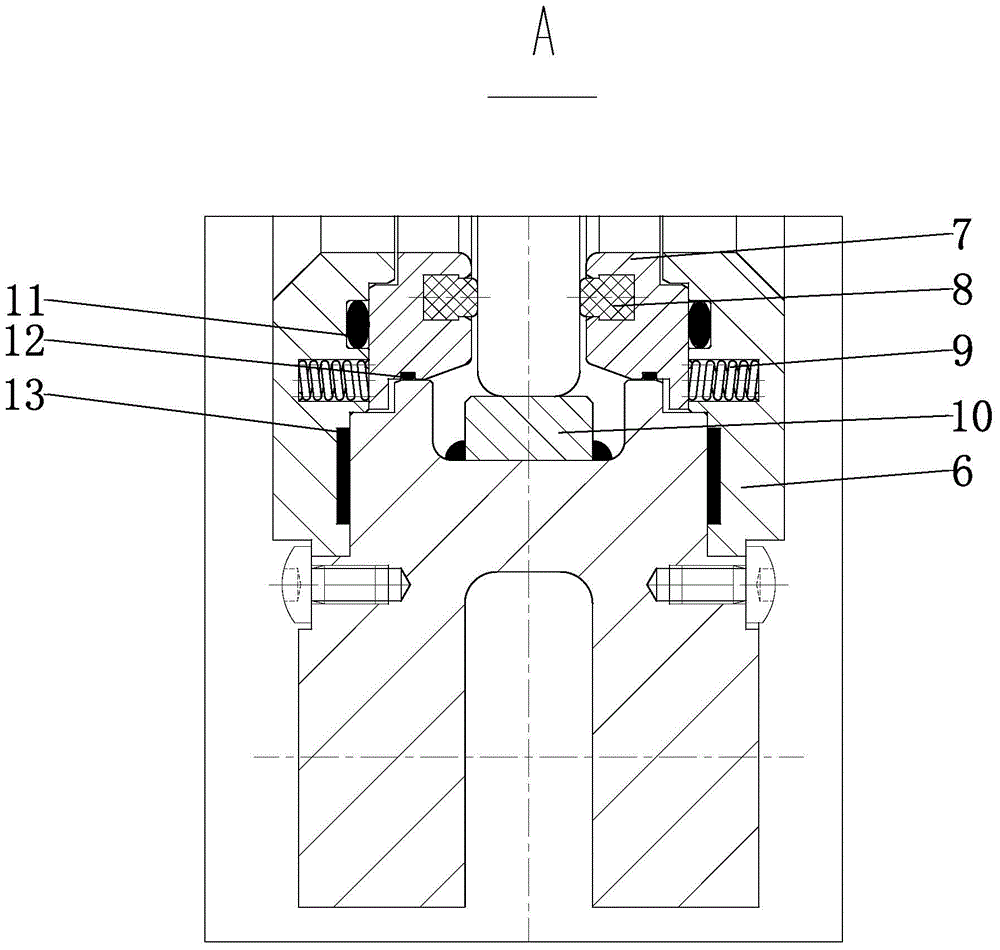

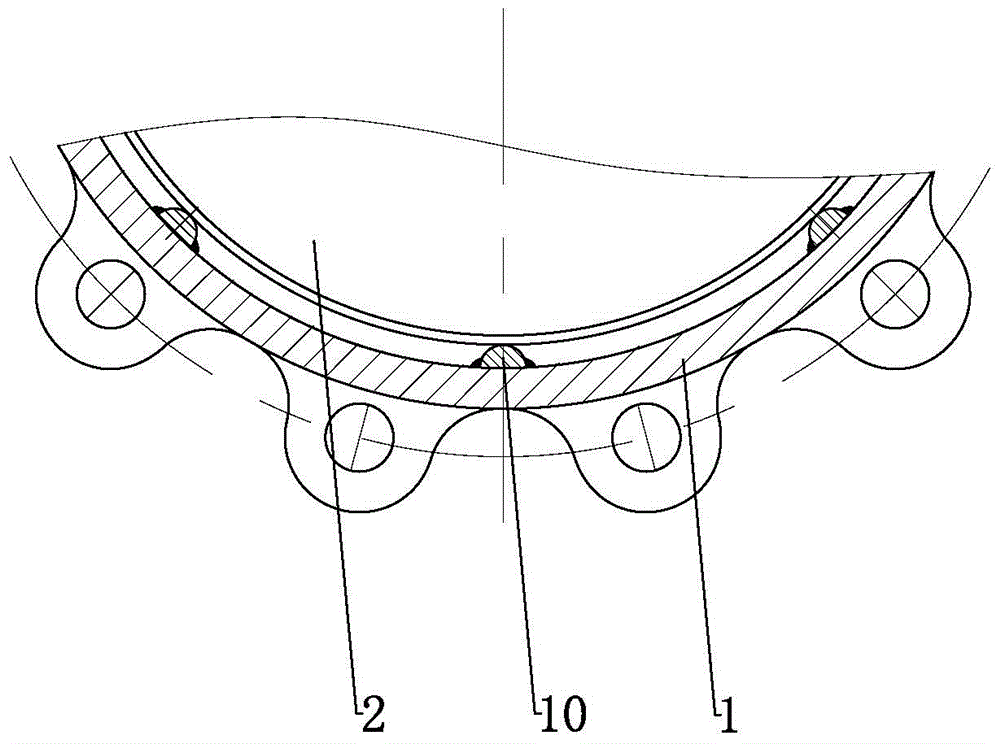

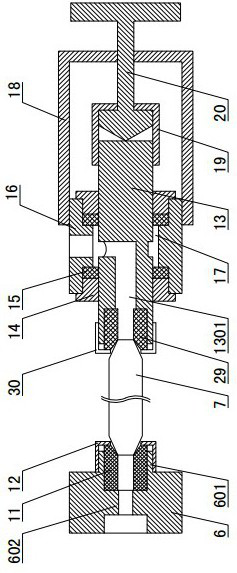

Valve rod sealing structure

The invention relates to a valve rod sealing structure. The valve rod sealing structure comprises a valve cover and a valve rod; the valve rod is arranged in a stuffing box hole of the valve cover in a partially penetrating mode; an elasticity assembly, V-shaped stuffing and a pressing sleeve are sequentially arranged between the valve rod and the stuffing box hole from bottom to top; the extension direction of the elasticity assembly is consistent with the axis direction of the valve rod; a leak detection and blocking assembly is arranged at the bottom of the pressing sleeve; and a pre-tightening assembly connected with the valve cover is arranged at the top of the pressing sleeve. The valve rod sealing structure can meet the sealing requirements under high-pressure and low-pressure working conditions and is good in compatibility; and whether sealing of the valve rod fails or not can be detected, blocking measures are provided for temporary sealing, medium leakage is avoided, and the using safety and reliability of a valve are improved.

Owner:DHV VALVE & FOUNDRY

Brushless direct-current magnetic isolation type water pump

InactiveCN104196731AReduce power consumptionImprove efficiencyPump componentsPump installationsImpellerElectrical polarity

The invention discloses a brushless direct-current magnetic isolation type water pump which comprises a motor body, a pump head and a pump base. The pump head is installed on the pump base. The pump base and an outer magnet rotor are arranged on the motor body. The outer magnet rotor is installed between the motor body and the pump base and completely sealed in the pump base. A plurality of pieces of outer rotor magnetic steel are pasted in the outer magnet rotor in the N-S sequence. An impeller is installed on the pump base and provided with inner rotor magnetic steel with the polarity distributed in the N-S sequence. The number of the pieces of the outer rotor magnetic steel is eight. The brushless direct-current magnetic isolation type water pump is simple in structure, reasonable in manufacturing, amphibious and high in effect, and the leakage problem can be effectively solved.

Owner:JIANGSU CHAOLI ELECTRIC

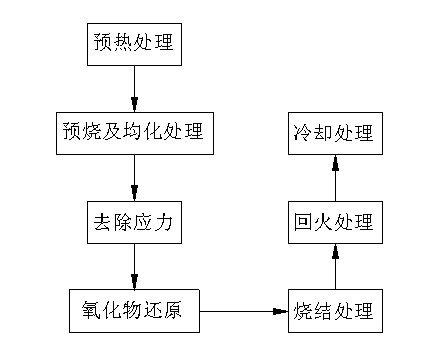

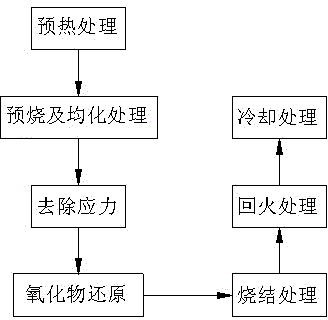

Integrated high-finish traceless injection molding die core and thermal treatment process thereof

The invention belongs to the field of injection molding dies, and in particular relates to an integrated high-finish traceless injection molding die core. The integrated high-finish traceless injection molding die core is characterized in that: the upper surface of the die core is provided with a square sunken groove, two pentagonal following water passages are arranged in the die core and positioned at the bottom of the sunken structure, and protruding structural blocks on two sides of the die core and a die core body form a T-shaped structure. A thermal treatment process of the die core comprises the following steps of: pre-heating treatment, pre-sintering and homogenizing treatment, stress removal, oxide reduction, sintering treatment, tempering treatment and cooling treatment. Compared with the prior art, formation of the integrated traceless injection molding die core can be realized, the sealing problem is avoided, medium leakage caused by improper sealing is avoided, and the following water passages of the integrated die core are closer to the surface of a die cavity so that hot and cold media can exchange heat with the surface of the die cavity more fully and quickly.

Owner:上海德奎久保田模具有限公司

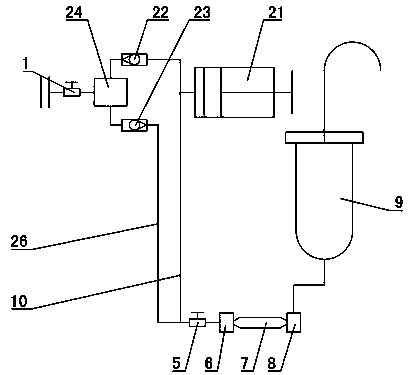

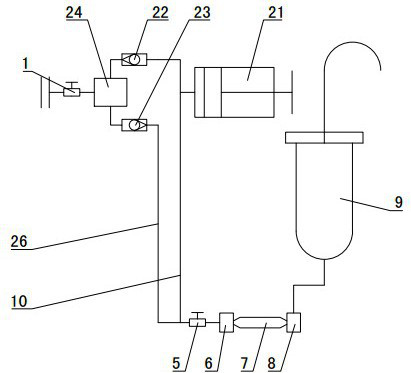

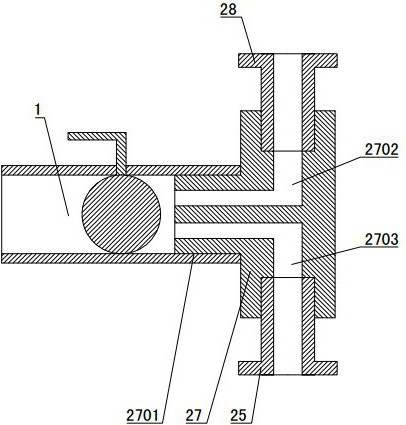

Single-point sampling detection system with micro pressure

InactiveCN109297764ARepresentativeAvoid pollutionWithdrawing sample devicesColor/spectral properties measurementsInlet valveEngineering

The invention discloses a single-point sampling detection system with micro pressure, which belongs to the technical filed of sampling device. The detection system is characterized in that: the inletend of a conveying tube (10) is communicated with the outlet end of the conveying tube, and the outlet end of the conveying tube (10) is connected in series with a color-comparison tube (7) and is communicated with an adsorption tank (9). The inlet end of a return tube (26) is communicated with the outlet end of the conveying tube (10), and the outlet end of the return tube (26) is communicated with an inlet tube. A sampling check valve (22) is provided between the conveying tube (10) and the inlet tube. A return check valve (23) is provided on the return tube (26). A sampling valve (5) is provided between the conveying tube (10) and the color-comparison tube (7). The inlet tube is provided with an inlet valve (1). A pressure boosting device is provided between the conveying tube (10) andthe inlet tube. According to the single-point sampling detection system with the micro pressure, samples taken by the single-point sampling detection system with the micro pressure are representativeand easy to operate during sampling; and medium leakage during sampling and pollution to the environment are avoided, thereby having a wide application range.

Owner:淄博绿丁环保设备技术有限公司 +1

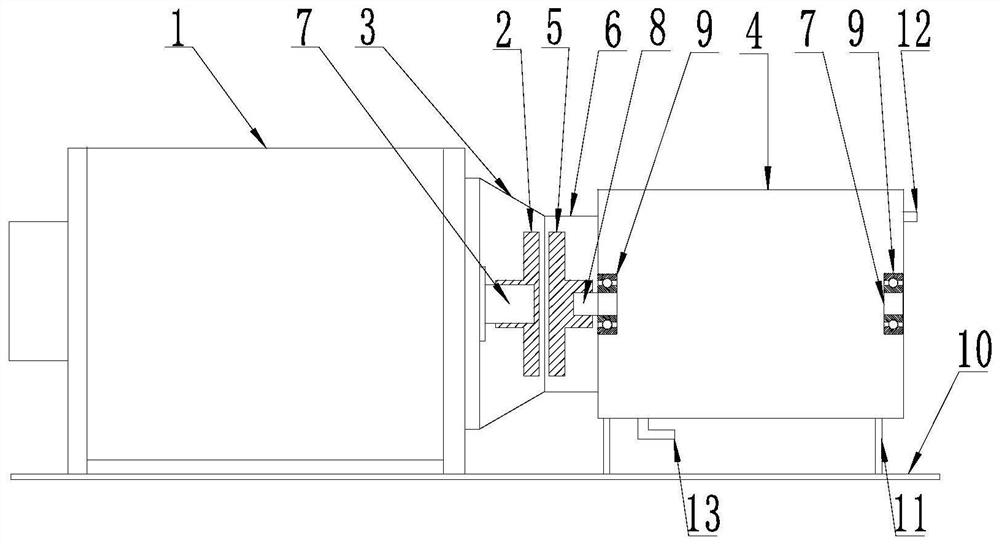

Compressor system adopting non-contact type coupling

PendingCN111927738APrevent media leakageResolve media leaksPositive displacement pump componentsPiston pumpsPhysicsDrive motor

The invention relates to a compressor system adopting a non-contact type coupling. The compressor system comprises a drive motor, a non-contact type coupling driving end, a driving end protective cover, a compressor, a non-contact type coupling driven end and a driven end sealing cover; the non-contact type coupling driving end and the non-contact type coupling driven end are made of permanent magnetic materials; a motor shaft is arranged in the drive motor; the end of the motor shaft is fixedly connected with the non-contact type coupling driving end; a compressor spindle is arranged in the compressor and is connected with the compressor through a bearing; and one end of the compressor spindle is fixedly connected with the non-contact type coupling driven end. The compressor system adoptsa non-contact type driving manner, effectively avoids leakage of media especially a flammable and explosive medium or a toxic or corrosive medium, can improve the safety performance of the compressorsystem, does not need lubricating oil for lubrication, avoids oil utilization and prevents the oil leaking problem.

Owner:山东凯格森能源科技有限公司

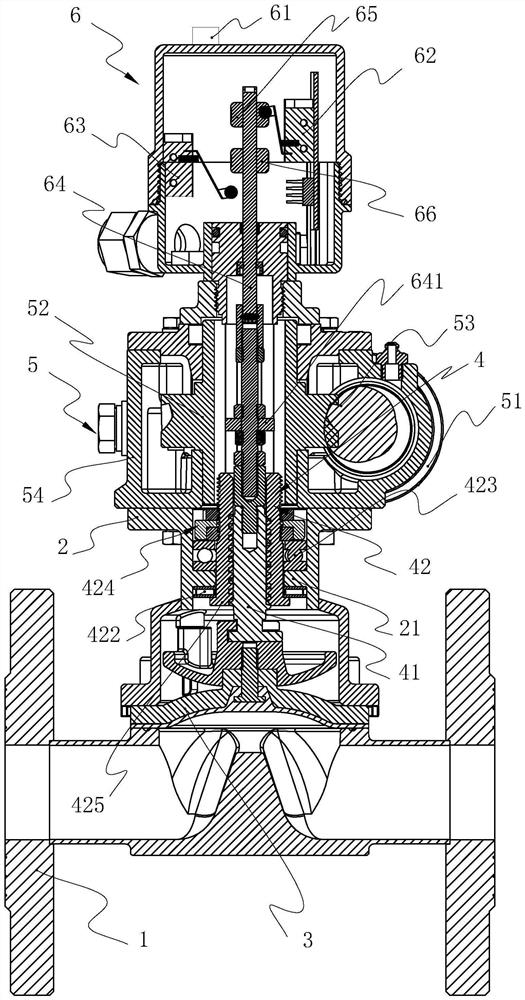

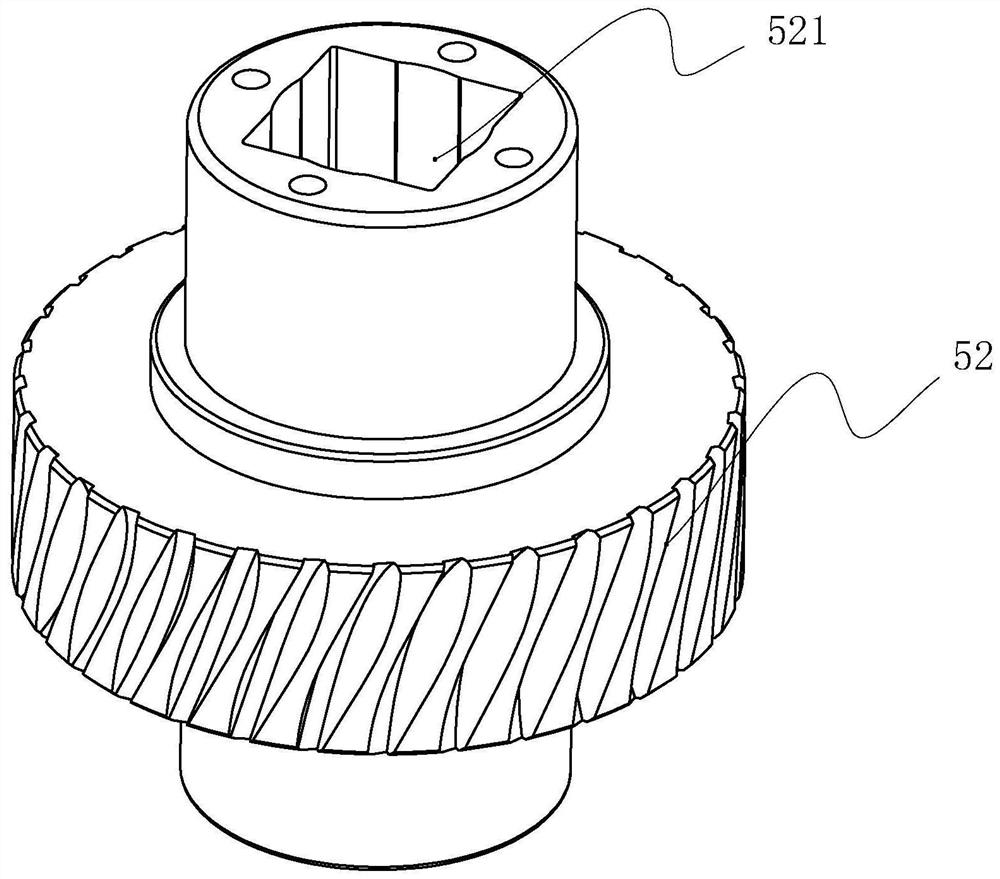

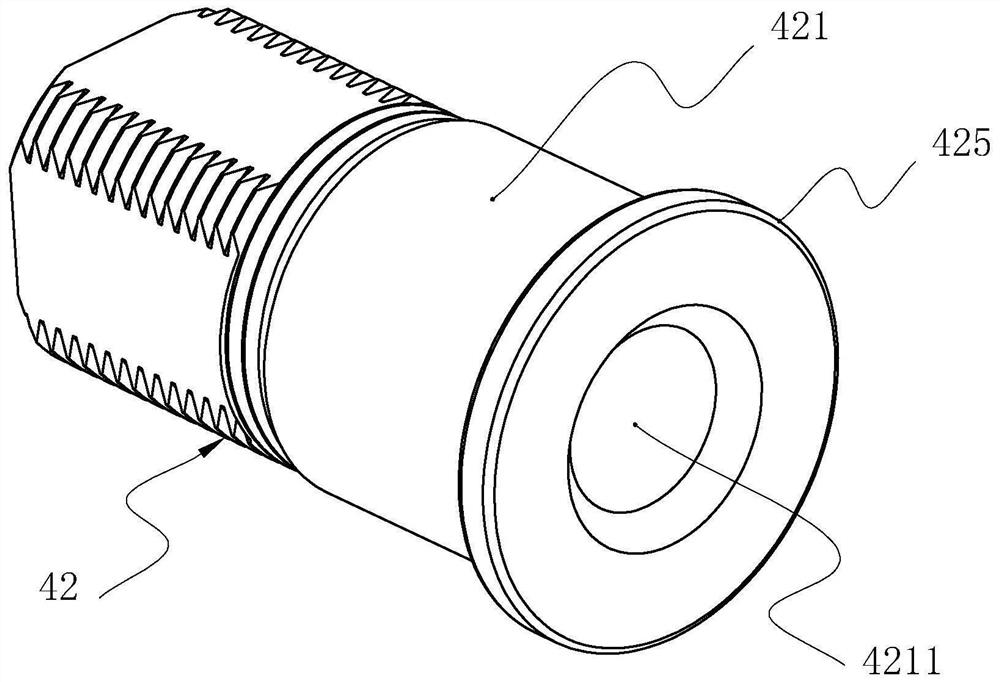

Electrically opened and closed threaded gate valve

PendingCN108825806APrevent tamperingReduce frictionOperating means/releasing devices for valvesJoints with sealing surfacesEngineeringVALVE PORT

The invention discloses an electrically opened and closed threaded gate valve. The threaded gate valve comprises a valve body; the left side of the valve body is connected with a water outlet, and theright side of the valve body is connected with a water inlet; the water outlet and the water inlet are both in through connection with the valve body; the top part of the valve body is provided witha motor case; a motor is arranged in the motor case; the output end of the motor is provided with a worm; the upper end of the worm is provided with a worm gear matched with the worm; the center of the worm gear is provided with a revolving shaft; a pipe casing nut sheathes each of the water inlet and the water outlet; the pipe casing nuts are capable of enabling the water inlet and the water outlet to connect with the ports of other pipelines, and thereby, the valve body is connected into a working pipeline; check rings are capable of increasing matching area when the water inlet and the water outlet are connected with the ports of the other pipelines, thereby realizing sealing better and enhancing installing and fixing strength; moreover, a sealing washer arranged on the rear side face of each check ring is capable of sealing the check ring and the corresponding pipe casing nut, and thereby, medium leakage is avoided; and when not in use, the pipe casing nut can freely move on the water inlet or water outlet so as to prevent the pipe casing nuts from being lost. The threaded gate valve is more reasonable in structural design and convenient to use, and is conducive to being popularized and used.

Owner:CHIZHOU XINJIA VALVE MFG CO LTD

Nuclear secondary tight-sealing high-temperature medium combined gate

InactiveCN109210220ADoes not affect downstream processesGuaranteed tightnessSlide valveHigh heatElectrical and Electronics engineering

Owner:LANZHOU HIGH PRESSURE VALVE

Stable anti-leakage lubricating gate valve

The invention discloses a stable anti-leakage lubricating gate valve which comprises a shell, valve covers and a spherical valve rod. The valve covers are fixedly connected to the shell through bolts. The spherical valve rod is arranged in the shell, and the two ends of the spherical valve rod extend out of the valve covers respectively. Locking rings are arranged at the positions, at the extending ends of the spherical valve rod, of the valve covers. The part, in the shell, of the spherical valve rod is provided with reinforcing rings. The parts, arranged at the inner end of the shell, of the valve covers are provided with sealing rings. A stable cover is arranged outside the middle of the part, arranged in the shell, of the spherical valve rod. A stable spring is arranged in the stable cover. An oil guide pipe is arranged on the shell. One end of the oil guide pipe stretches into the shell, and the other end of the oil guide pipe stretches out of the shell and is sealed by a sealing cover. According to the scheme, stability during running is provided, the service life is greatly prolonged, and the leakage of the gate valve is effectively avoided.

Owner:SUZHOU SONGSHUN HARDWARE

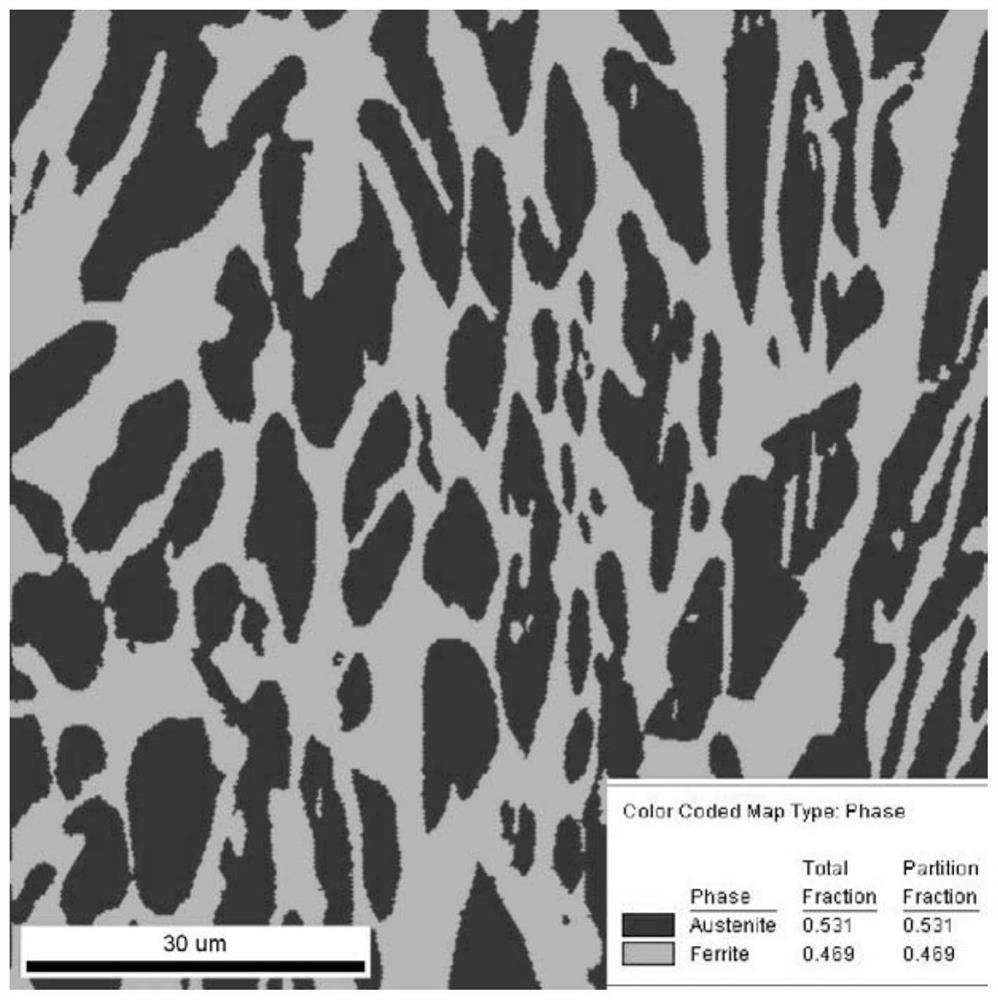

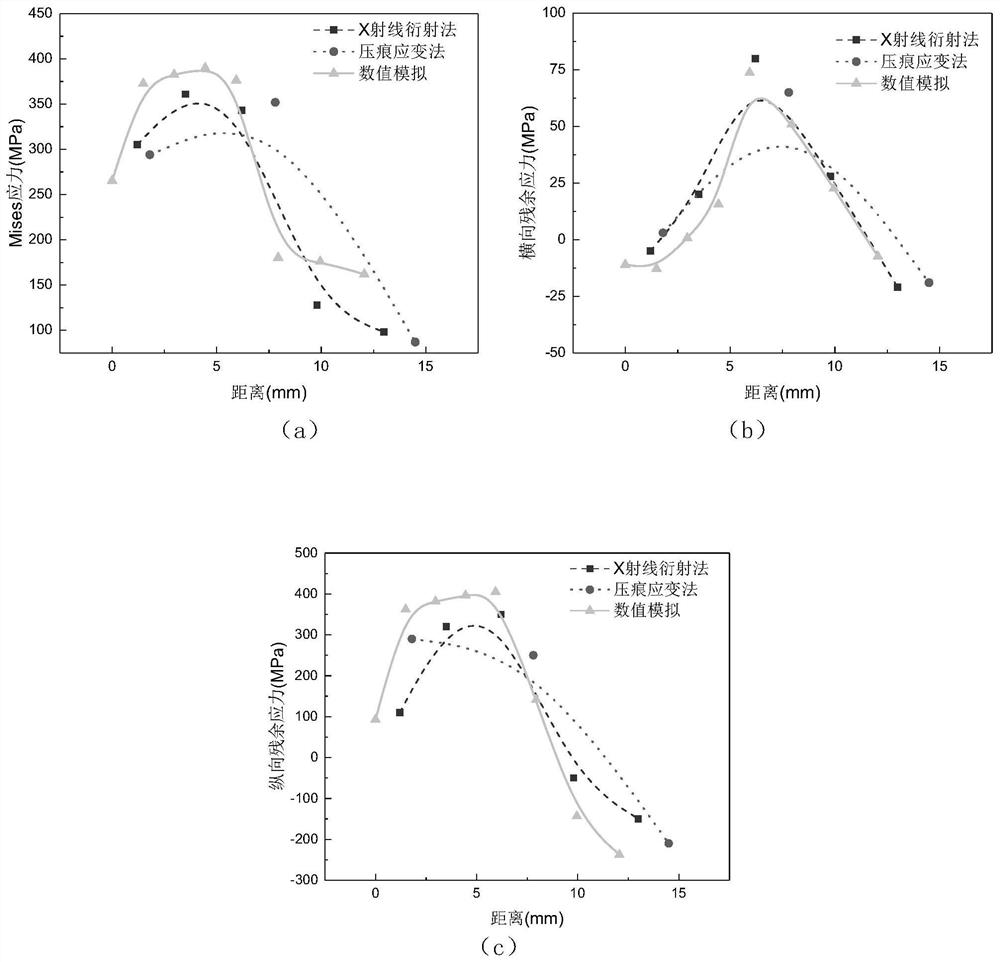

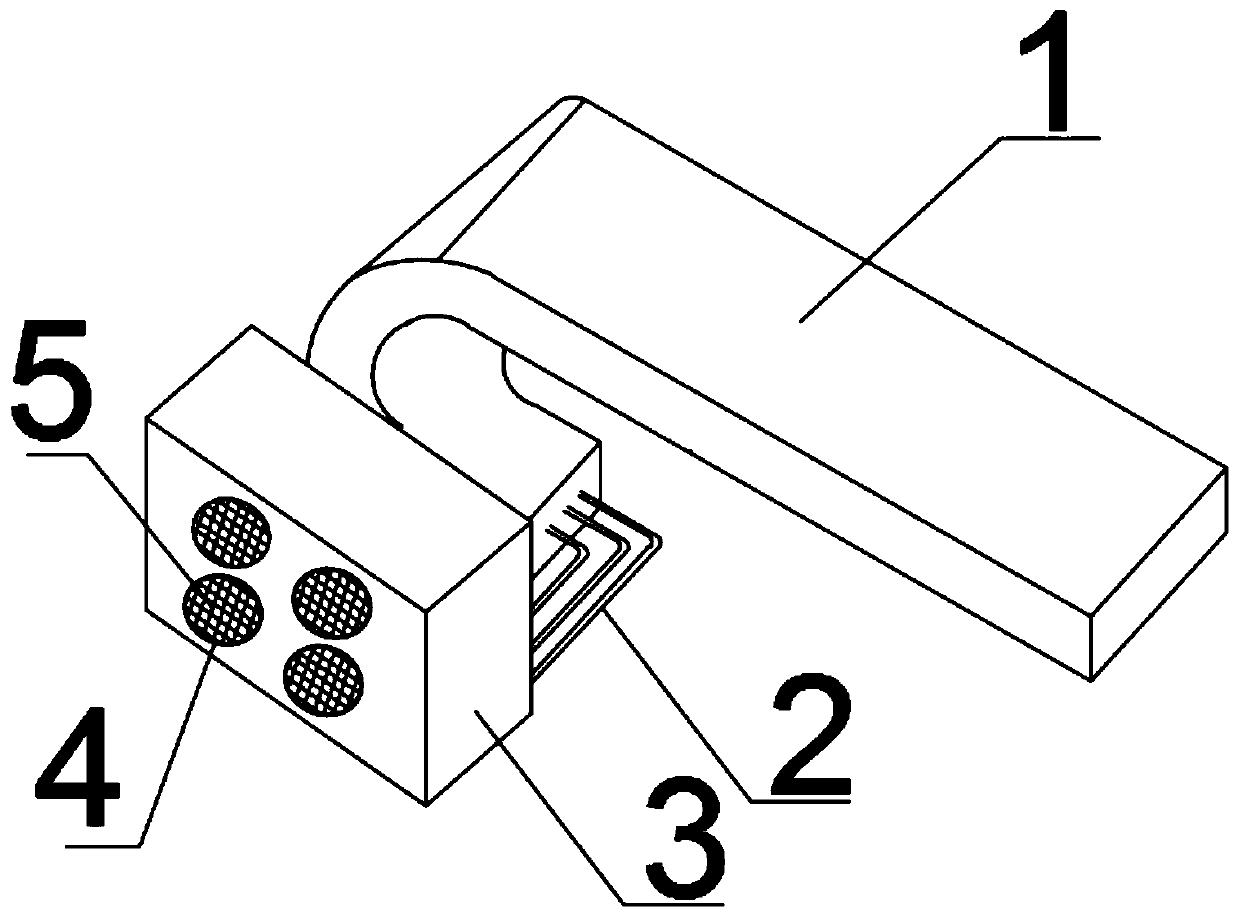

A hybrid welding method for duplex stainless steel heat exchange plates based on residual stress control

ActiveCN110405372BImprove mechanical propertiesEnhanced resistance to stress corrosion crackingWelding apparatusWelding residual stressSS - Stainless steel

The invention relates to the technical field of plate and shell heat exchangers, and provides a composite welding method for duplex stainless steel heat exchange plates based on residual stress regulation. Welding residual stress of the heat exchanger core, and adjust the dual-phase ratio of the duplex stainless steel welded joints to avoid the precipitation of brittle phases and improve the resistance to pitting corrosion; the hybrid welding method of resistance welding and argon arc welding can effectively reduce the residual stress, To control the deformation of the plate, the second argon arc welding is performed after the first resistance welding, in addition to the role of double sealing, the sealing effect is better, and the medium leakage caused by the failure of one welding seam is avoided; argon arc welding The heat input can also effectively play a metallurgical role, promote the precipitation of austenite phase, reduce the ferrite content, optimize the ratio of the two phases, improve the mechanical properties of the welded joint, and enhance the stress corrosion cracking resistance of the welded joint.

Owner:JIANGSU GELAN ENVIRONMENTAL TECH CO LTD

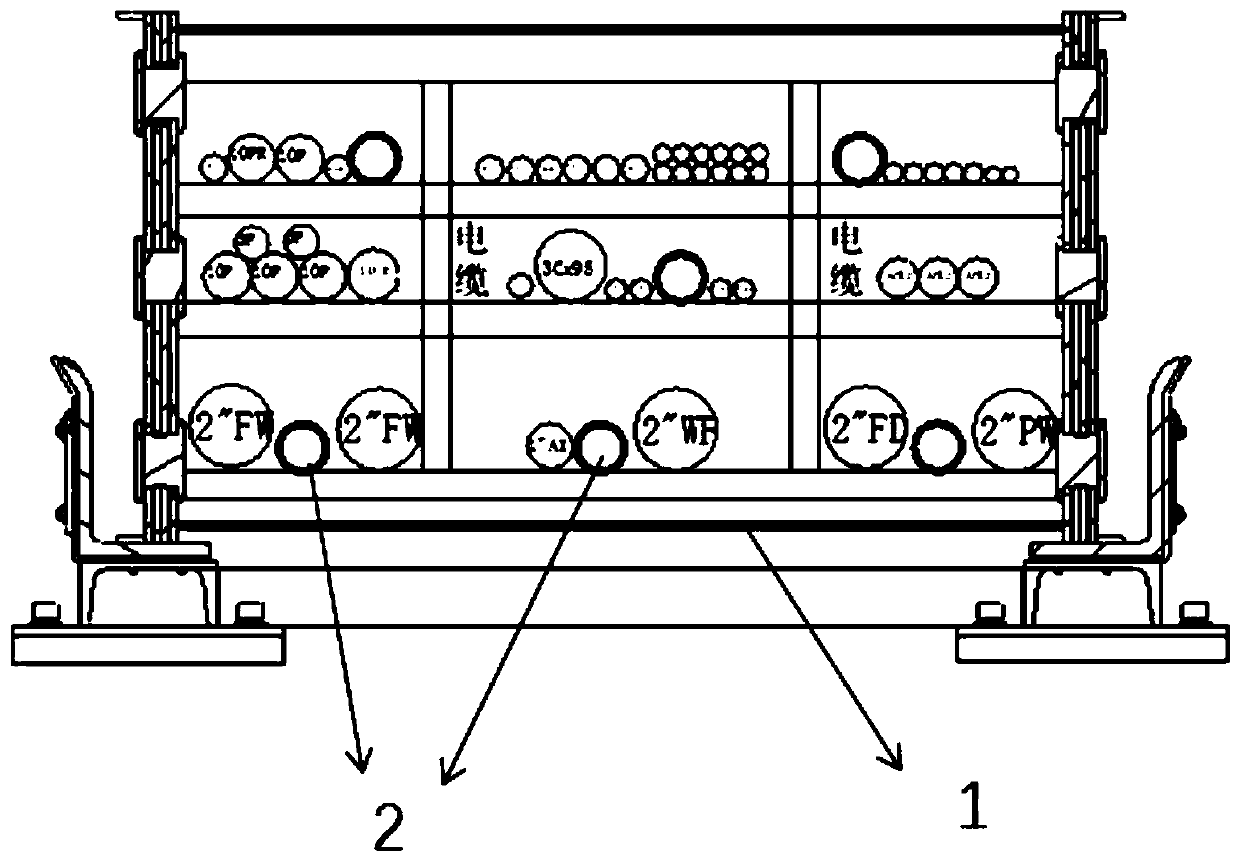

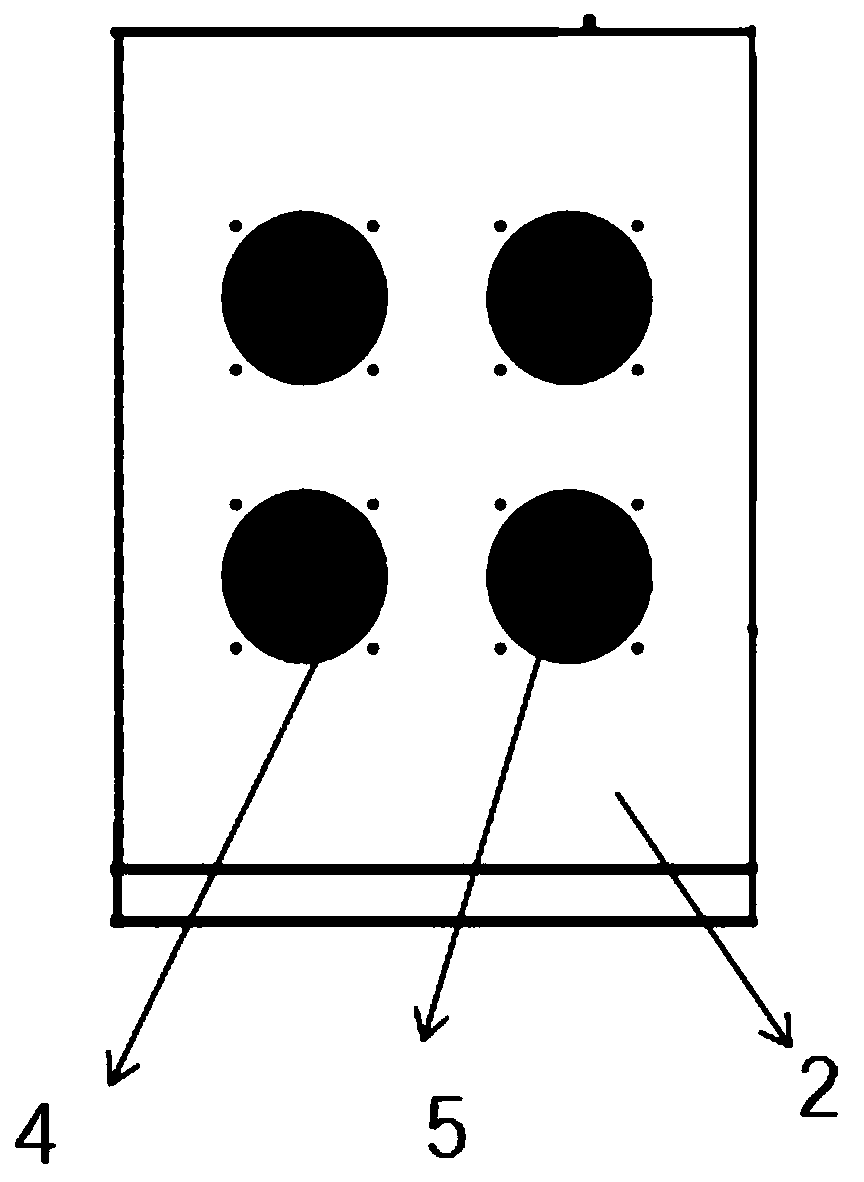

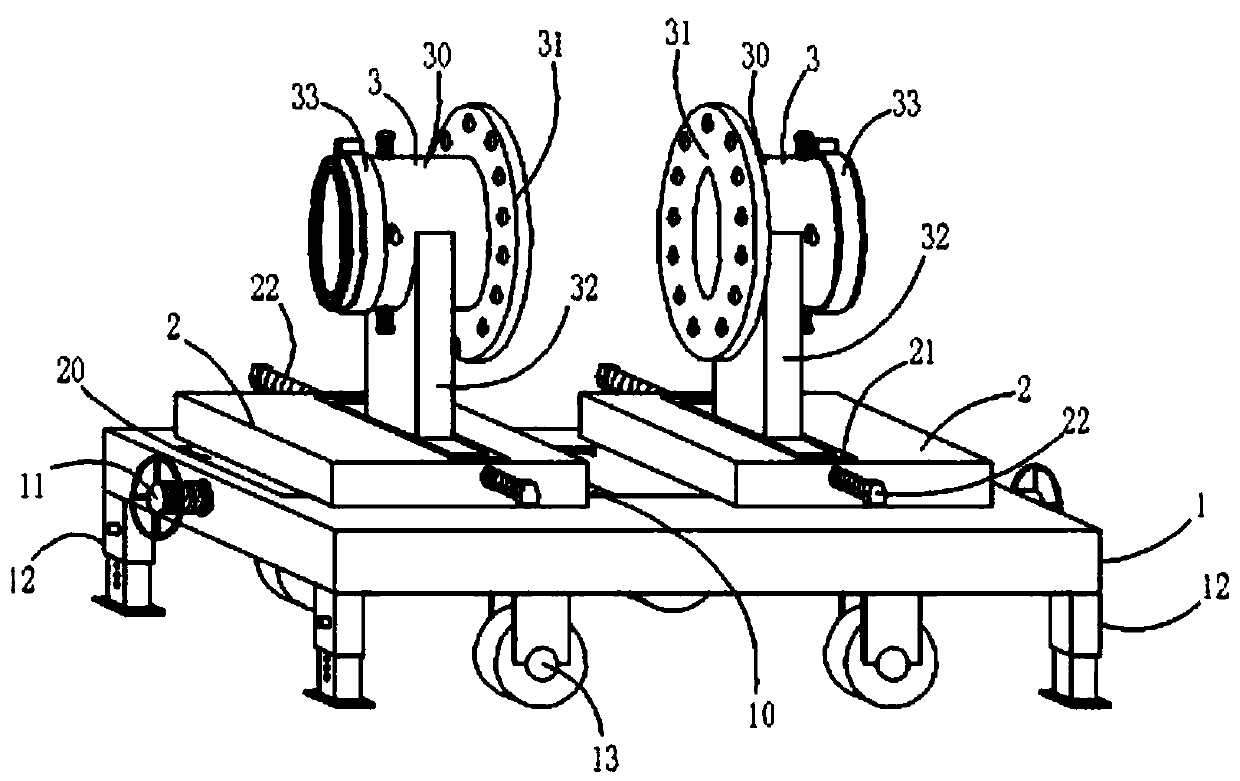

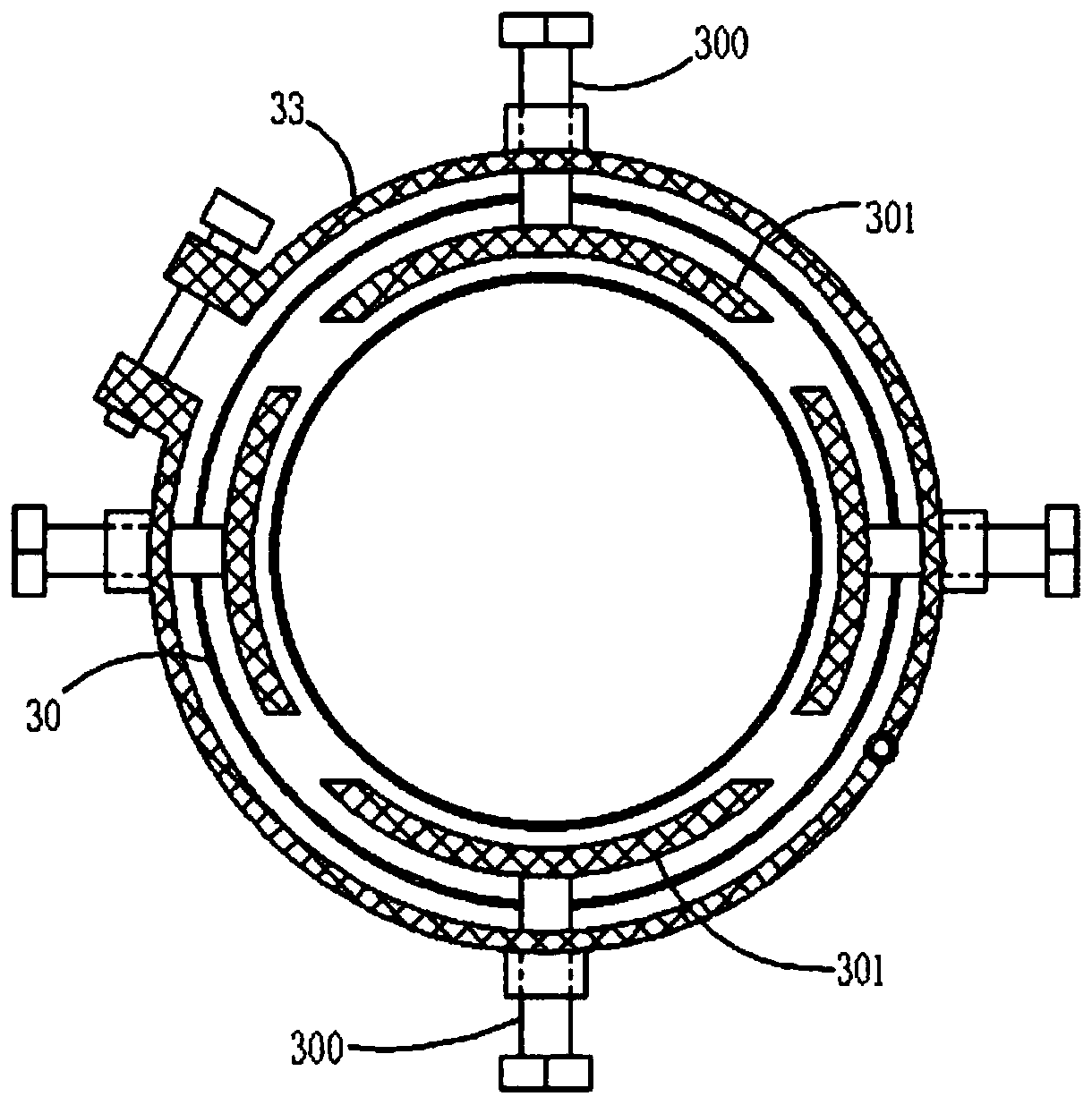

Heating device and method for closed type towing chain heat preservation

PendingCN111577835AReduce freezingGuaranteed liquidityHauling chainsHoisting chainsThermodynamicsLiquid medium

The invention provides a heating device and method for closed type towing chain heat preservation. The heating device comprises an air heater. A fan and an electric heater are arranged in the air heater and connected with a power source. Air inlets are formed in the air inlet side of the air heater, and air outlets are formed in the air outlet side of the air heater and connected with heating pipes. The heating pipes penetrate through a closed type heat preservation towing chain, and heat dissipation holes are formed in the heating pipes. The heating device and method for closed type towing chain heat preservation can solve the problem that liquid media in pipelines in towing chains are frozen in winter, guarantee normal operation of well drilling and well repair and prevent cables againstfrost cracks.

Owner:CNOOC ENERGY DEV EQUIP TECH

A steel-sheathed steel steam direct-buried thermal insulation pipe and its quick connection device

ActiveCN109282109BEven insulationHigh temperature resistantFlanged jointsThermal insulationSteel jacketInsulation layer

The invention discloses a steel jacket steel steam buried insulated pipe and a fast connecting device thereof. The insulated pipe comprises an inner work pipe, an insulating layer and an outer protection pipe. The outer protection pipe is arranged on the outer portion of the inner work pipe in a sleeving manner. The insulating layer is arranged between the inner work pipe and the outer protectionpipe. The outer wall of the inner work pipe is coated with an anti-corrosion material, and centrifugal glass wool serves as the material of the insulating layer. The fast connecting device comprises amounting plate, movement blocks and butt-joint assemblies. A sliding groove is formed in the mounting plate, the left side and the right side of the mounting plate are in threaded connection with lead screws, the movement blocks are used for adjusting the positions of insulated pipes at the two ends, and the butt-joint assemblies are used for connecting the insulated pipes at the two ends. The insulated pipe has high corrosion resistance and the heat retaining property, the two segments of the insulated pipe can be firmly connected without welding, and the heating power transmission efficiency is improved.

Owner:JIANGSU TIANRUN PIPE CO LTD

Hydraulic cylinder self-locking mechanical mechanism for cleaning container and self-locking method of hydraulic cylinder self-locking mechanical mechanism

ActiveCN108757641APrevent leakageGuaranteed coaxial movementHollow article cleaningFluid-pressure actuatorsHydraulic cylinderSelf locking

The invention relates to a hydraulic cylinder self-locking mechanical mechanism for cleaning a container and a self-locking method of the hydraulic cylinder self-locking mechanical mechanism. The hydraulic cylinder self-locking mechanical mechanism comprises a hydraulic cylinder body and a piston, wherein the piston is arranged inside the hydraulic cylinder body. The hydraulic cylinder self-locking mechanical mechanism is characterized in that the hydraulic cylinder self-locking mechanical mechanism comprises a plug pin groove, a self-locking pin, a driving assembly, a closed type filling mechanism and filler, wherein the plug pin groove is formed in the piston; one end of the self-locking pin penetrates into the hydraulic cylinder body and can penetrate into the plug pin groove; the driving assembly is used for driving the self-locking pin to slide in the plug pin groove in the axial direction; the closed type filling mechanism is arranged on the driving assembly; and the filler is arranged in the closed type filling mechanism. When the closed type filling mechanism works, the filler enters a gap formed between the self-locking pin and the hydraulic cylinder body and / or a gap formed between the closed type filling mechanism and the driving assembly, so that sealing of the hydraulic cylinder body is completed. The self-locking method of the hydraulic cylinder self-locking mechanical mechanism comprises the steps of 1, self-locking; 2, sealing; and 3, reset. The hydraulic cylinder self-locking mechanical mechanism and the self-locking method thereof have the beneficial effects that the structure is simple, sealing performance is great, and safety performance is high.

Owner:ZHEJIANG JUHUA EQUIP MFG CO LTD

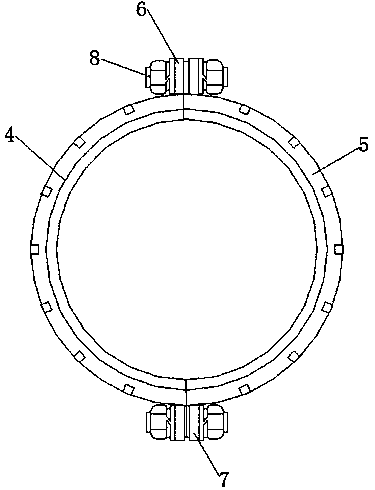

Production method of pipeline compensator

InactiveCN107869626AGood sealing performancePrevent media leakageEngine sealsPipe elementsCoalPower station

The invention provides a production method of a pipeline compensator comprising a circular lantern ring body with a circular groove which is internally provided with a sealing ring. The circular lantern ring body is composed of a first circular arc chuck ring and a second circular arc chuck ring. According to the production method provided by the invention, the self-tightening force of the rubbersealing ring and medium pressure are used for sealing, and the sealing performance is good; the leakage of media is prevented, and the service life of the compensator is prolonged effectively; and themaintenance cost of a pipeline is reduced. In addition, the pipeline compensator is compact and rational in structure and wide in application scope, and can meet the compensation requirements of pulverized coal pipelines of large power station boilers and other multidimensional deformation compensation requirements.

Owner:合肥果成科技有限公司

Anti-seismic structure for inner tank of double-hull cryogenic tank

ActiveCN108861170BAvoid the problem of low temperature damageAvoid lift-off damageLarge containersEarthquake resistant structuresGeotechnical engineering

The invention provides an aseismic structure in a double-shell low-temperature in-tank tank. The aseismic structure comprises an anchor belt box, a cover body and an anchor belt, wherein the anchor belt box is arranged in a bearing table foundation, the top end is exposed out of the upper surface of the bearing table foundation and penetrates through an outer tank base plate to be in sealed welding to the outer tank base plate, the cover body is exposed out of the lower surface of the bearing table foundation and seals the bottom end of the anchor belt box, the lower end of the anchor belt penetrates the anchor belt box to be connected with the cover body, and the upper end of the anchor belt is movably connected with an inner tank wall. According to the aseismic structure, the anchor beltpenetrates the anchor belt box in the concrete bearing table foundation to be connected with the exposed cover body, the anchor belt is not in contact with the anchor belt box and is not in contact with the outer tank base plate, and the problem of low-temperature damage of the outer tank and the bearing table foundation due to the fact that cold of a low-temperature inner tank is transmitted toan outer tank and the bearing table foundation is solved; tearing force damage caused by the anchor belt to the outer tank base plate during an earthquake is avoided; the inner tank wall is movably connected to the upper end of the anchor belt, additional tension generated by the anchor belt to the inner tank wall can be avoided, the low-temperature inner tank is fixed during the earthquake, the earthquake force of a tank body is directly transmitted to a pressure bearing platform, and lift-off damage is prevented from being generated on the low-temperature inner tank during the earthquake.

Owner:SINOPEC ENG +1

Ceramic sealing type rotational steam valve

InactiveCN105909813APrevent media leakageNo leakageSlide valveValve housingsScrew threadSteam system

The invention provides a ceramic sealing type rotational steam valve, relates to a steam valve. The ceramic sealing type rotational steam valve is of a non-external-leakage structure which is manufactured from a ceramic sealing material and in a rotating sealing manner; the ceramic sealing type rotational steam valve is applicable to a steam system and a high-temperature condensation water condition. The ceramic sealing type rotational steam valve is provided with a valve body, a lower sealing ring, an upper sealing cover, a compressing nut, an adjusting gasket, an operating rod and limiting columns, wherein the lower sealing ring is mounted to the bottom part of an inner chamber of the valve body and is integrally connected with the valve body; the upper sealing cover is arranged at the upper part of the lower sealing ring; a cross boss is arranged at the lower end of the operating rod; a cross groove is formed in the top part of the upper sealing cover; the cross boss is sleeved with a cross concave platform; the operating rod can drive the upper sealing cover to rotate; an inner hole of the compressing nut is provided with a concave platform; outer threads are formed in an outer circle of the compressing nut; the adjusting gasket is mounted into the concave platform at the inner hole of the compressing nut; the operating rod is sleeved with the inner hole of the compressing nut and inner hole of the adjusting gasket; the outer threads in the outer circles of the compressing nut are screwed into an inner chamber of the valve body and are screwed and compressed with the inner threads in the upper part; the two limiting columns are arranged on the upper end surface of the valve body and used for limiting a switch valve.

Owner:YINGQIAO MACHINERY MFG

Integral high-gloss non-marking injection mold core and its heat treatment process

ActiveCN102179904BFully rapid heat exchangeNo sealing issuesNuclear engineeringInjection molding machine

The invention belongs to the field of injection molding dies, and in particular relates to an integrated high-finish traceless injection molding die core. The integrated high-finish traceless injection molding die core is characterized in that: the upper surface of the die core is provided with a square sunken groove, two pentagonal following water passages are arranged in the die core and positioned at the bottom of the sunken structure, and protruding structural blocks on two sides of the die core and a die core body form a T-shaped structure. A thermal treatment process of the die core comprises the following steps of: pre-heating treatment, pre-sintering and homogenizing treatment, stress removal, oxide reduction, sintering treatment, tempering treatment and cooling treatment. Compared with the prior art, formation of the integrated traceless injection molding die core can be realized, the sealing problem is avoided, medium leakage caused by improper sealing is avoided, and the following water passages of the integrated die core are closer to the surface of a die cavity so that hot and cold media can exchange heat with the surface of the die cavity more fully and quickly.

Owner:上海德奎久保田模具有限公司

Low-torque diaphragm valve with opening and closing indicating device

PendingCN114263760AReduce operating torqueHigh output torqueDiaphragm valvesOperating means/releasing devices for valvesPhysicsEngineering

The invention relates to a low-torque diaphragm valve with an opening and closing indicating device, which is characterized in that a valve rod comprises a lifting valve rod and a rotating rod sleeve, one end of the rotating rod sleeve is in linkage connection with an operating mechanism, and the other end of the rotating rod sleeve is rotatably fixed with a valve cover; and the other end of the lifting valve rod is arranged in the rotating rod sleeve, is connected with the signal feedback device and is in threaded connection with the rotating rod sleeve. The invention has the beneficial effects that the valve rod is split to form the lifting valve rod and the rotating rod sleeve, and the traditional hard driving is changed into rotating spiral driving, so that the operation torque of an operation mechanism can be reduced to the greatest extent; secondly, when the rotating rod sleeve spirally ascends or descends, the signal feedback device synchronously sends out an opening or closing signal, and an operator is reminded in real time to avoid insufficient medium flow or medium leakage caused by insufficient opening or untight closing of the diaphragm valve and damage of the diaphragm piece due to excessive pressure; the use safety of the diaphragm is ensured; and the service life of the diaphragm is prolonged.

Owner:温州诺盟科技有限公司

Dry gas sealing device of nuclear fuel circulating pump

PendingCN112268112AImprove reliabilityPrevent media leakageEngine sealsNuclear energy generationPhysicsDry gas seal

The invention discloses a dry gas sealing device of a nuclear fuel circulating pump. The dry gas sealing device comprises a shaft sleeve, a spring seat, a safety sealing ring and a sealing cavity body, wherein the shaft sleeve is arranged on a rotating shaft in a sleeving mode. The shaft sleeve penetrates through an end cover, the spring seat and the sealing cavity body. The sealing cavity body internally comprises a movable ring and static rings. An annular protrusion is arranged on the outer side of the shaft sleeve. The static rings and the movable ring are symmetrically arranged relative to the annular protrusion. The static rings are arranged on the two sides of the movable ring. The movable ring is fixedly connected with the shaft sleeve. The spring seat is arranged at one end of each static ring. The dry gas sealing device has the advantages that on one hand, medium leakage is eradicated, and on the other hand, the reliability of the sealing ring is enhanced; and the sealing ring is assisted by selecting a nuclear-radiation-resistant and high-temperature-resistant material, so that the sealing ring can stably and safely operate for a long time under the working conditions ofnuclear radiation and high temperature of the nuclear fuel circulating pump completely, and the advantages of being incomparable with conventional sealing under the working conditions, good in durability, long in service life and higher in reliability and safety are achieved.

Owner:CHENGDU YITONG SEAL

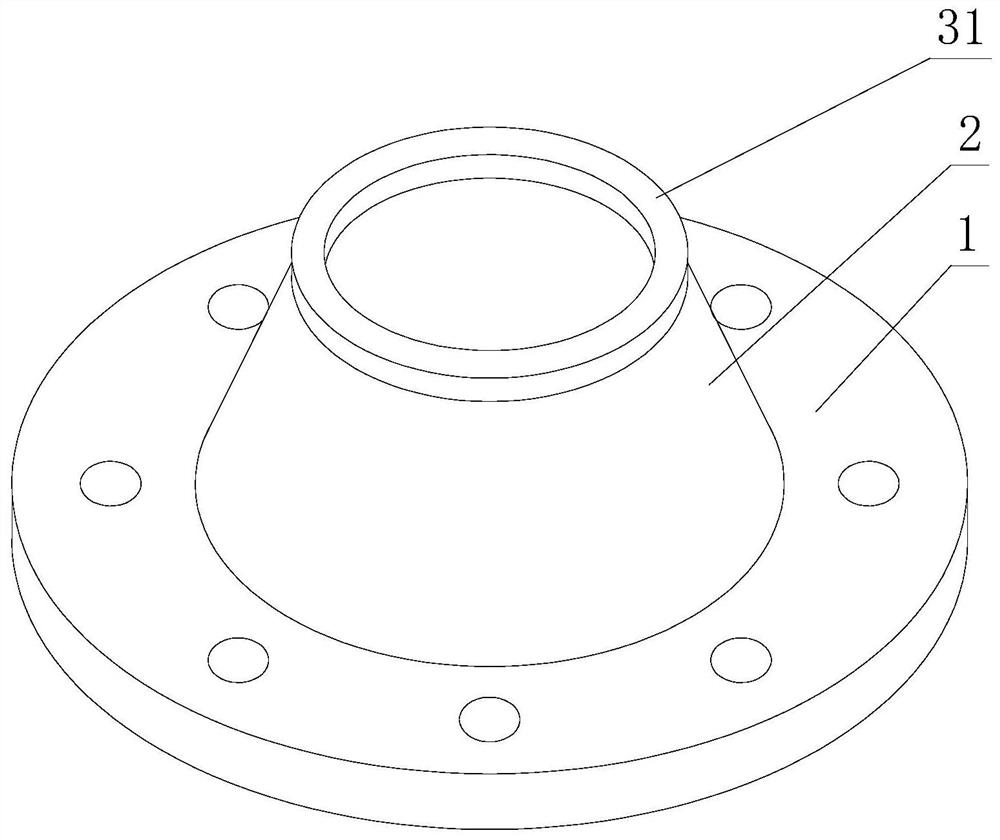

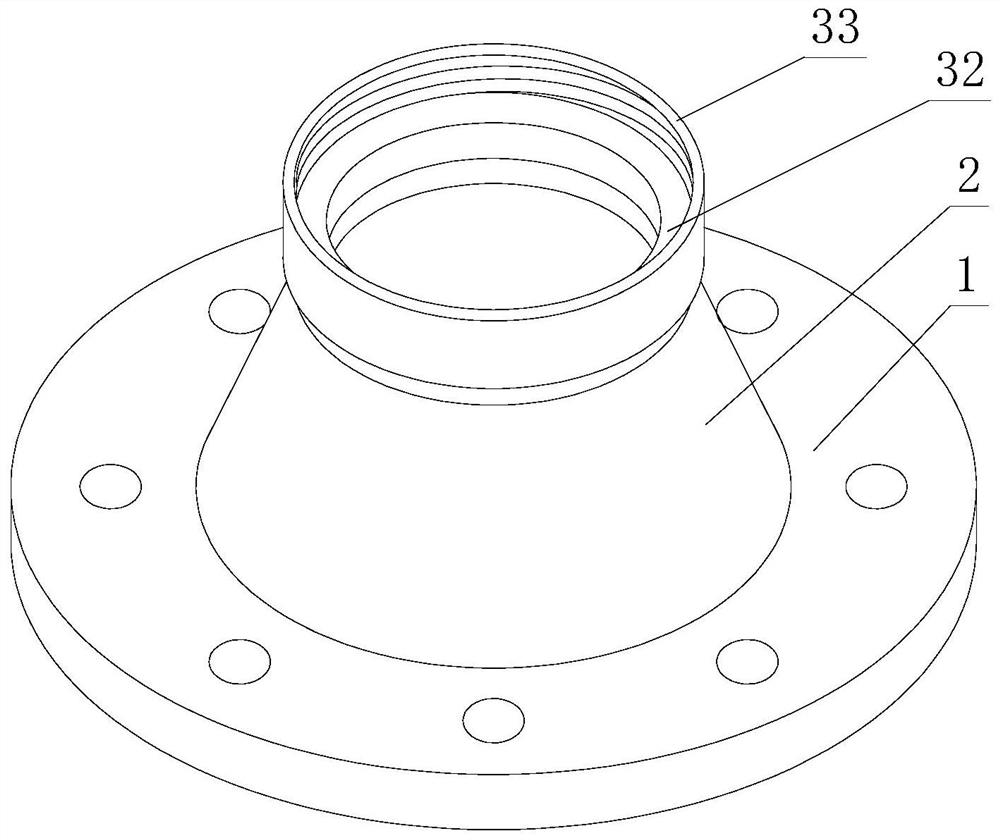

Welding neck flange with assembling ring preset at neck opening and implementation method of welding neck flange

InactiveCN113606403APrevent media leakageEasy to disassembleFlanged jointsStress concentrationIndustrial engineering

The invention discloses a welding neck flange with an assembling ring preset at a neck opening and an implementation method of the welding neck flange. The outer wall of a middle ring is in contact with an upper ring, a deformation block is mounted in a gap between the upper ring and the middle ring, the upper ring and the middle ring are both in contact with a basic welding ring, specifically, the deformation block with the cross section in a transverse X shape has certain elasticity in the assembly process, the corner of the deformation block is rounded to reduce the stress concentration phenomenon, a sealing ring can prevent external impurities such as dust and water from invading and guarantee cleanliness, a retaining ring section is buckled in the gap between the bottom ring and the middle ring, a protruding section is connected with the basic welding ring in a threaded fit mode, and therefore the upper ring installation process is simple and convenient; and meanwhile, according to the implementation method of the welding neck flange with the assembling ring preset at the neck opening, the bottom ring and the upper ring are installed firstly, then the deformation block and the middle ring are installed, finally the upper ring is aligned with the basic welding ring, the outer wall of the upper ring is rotated, the upper ring is in threaded fit with the basic welding ring, the whole assembling process is simple and convenient, and meanwhile the welding neck flange is easy to disassemble and assemble and good in practicability.

Owner:ANHUI TONGSHENG RING

Two-way sealing knife gate valve with self-sealing and elastic compensating seat

The invention relates to a knife gate valve, in particular to a two-way sealed knife gate valve with self-sealing and elastic compensation valve seats, and belongs to the technical field of the knife gate valve. The knife gate valve comprises a valve body, the two sides of a through cavity of the valve body are provided with pressing rings, bases are arranged in the pressing rings and springs used for pressing the bases are arranged between the bases and the pressing rings; the sides, facing a knife board, of the bases are provided with T-shaped valve seat slots in which T-shaped valve seats are connected, and the inner sides of the valve seats can be closely in contact with the knife board by pressing the springs. According to the knife gate valve provided by the invention, the valve seat can be enabled to press to the knife board all the time due to the poor stressed area of the valve seat; furthermore, the valve can be sealed well at the low pressure working station by additionally installing the compression springs; in addition, the compression springs can be effectively isolated by the spring isolation structure, therefore the compression springs can be prevented from being locked because compression spring mounting holes are blocked by a sizing agent, non-pure mediums containing particulates and the like.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

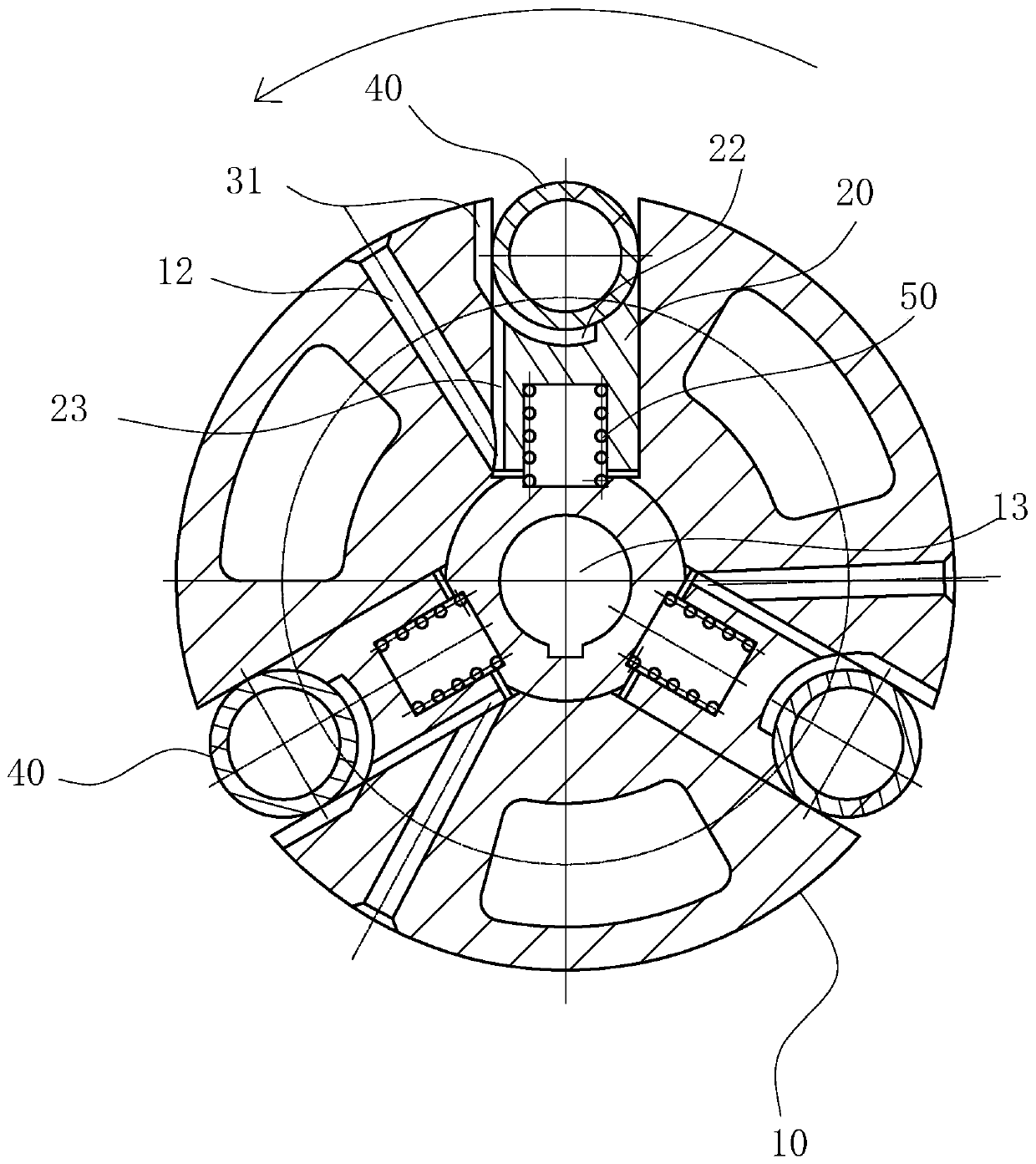

Rolling type sliding vane pump rotor

PendingCN110131161APrevent media leakageReduce volume lossRotary piston pumpsRotary piston liquid enginesVolume lossAxial length

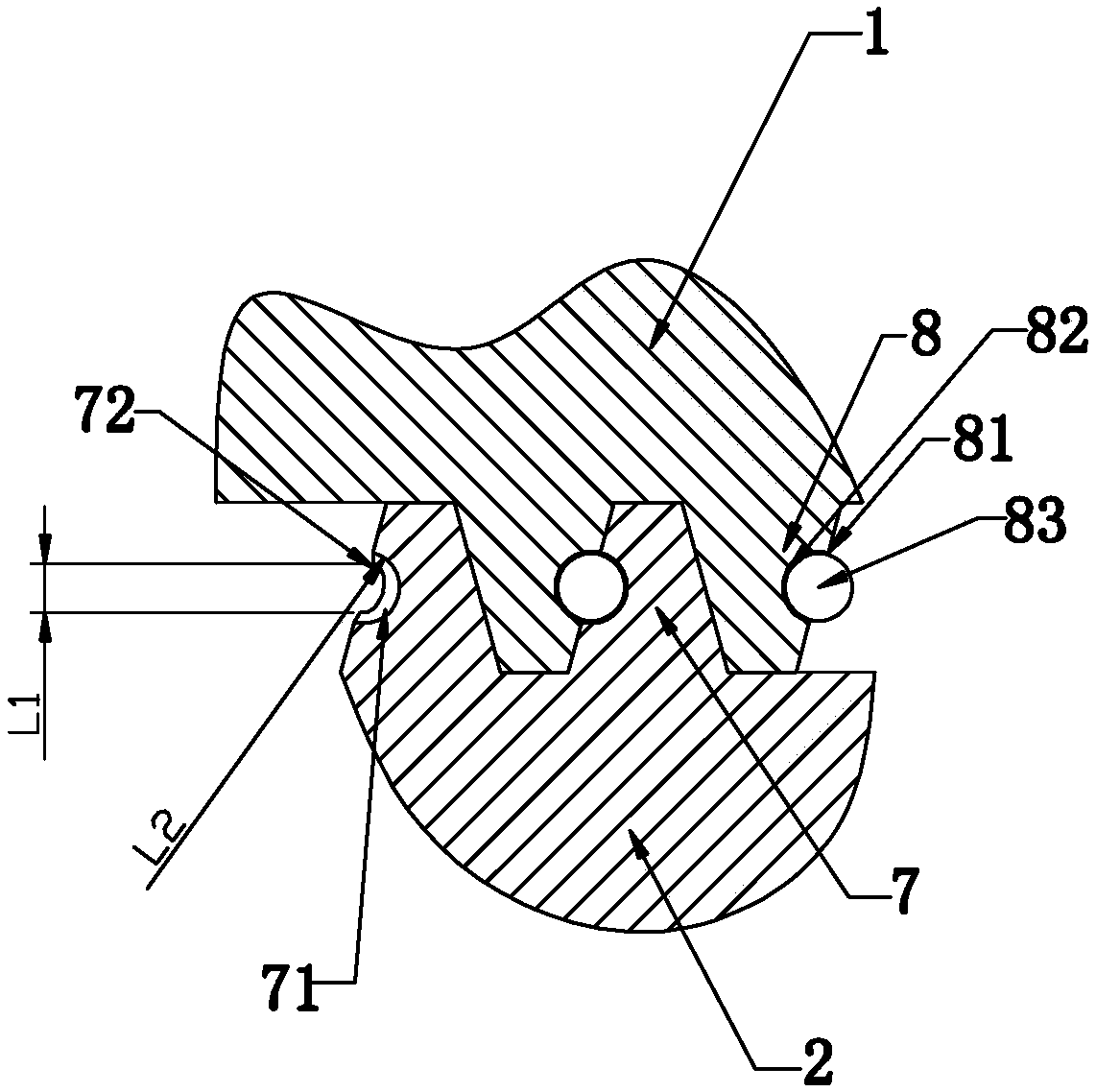

The invention relates to a rolling type sliding vane pump rotor comprising a rotor body and a plurality of sliding vane bodies. The rotor body is sequentially provided with a plurality of sliding grooves in the circumferential direction of the rotor body, and the sliding vane bodies are arranged in the corresponding sliding grooves in a manner of being capable of sliding in the radial direction; the rolling type sliding vane pump rotor further comprises pin rollers rotationally arranged at the tops of the sliding vane bodies in a matched manner, and the tops of the sliding vane bodies are provided with arc pin roller grooves being capable of containing the pin rollers and being in sealing contact with the outer circles of the pin rollers; and each sliding groove extends in the axial direction of the rotor body and penetrates to the two ends of the rotor body in the axial direction, and the axial length of the pin rollers and the axial length of the sliding vane bodies are both the sameas the axial length of the rotor body. The rolling type sliding vane pump rotor effectively avoids the volume loss caused by components such as pin roller seats in the prior art, greatly improves theefficiency of a sliding vane pump and avoids use of connecting members such as bearings, so that the service life is long, and a medium containing impurity particles can be effectively transported.

Owner:NINGBO HELI MECHANICAL PUMP CO LTD

A micro-pressure single-point sampling detection system

InactiveCN109297764BRepresentativeAvoid pollutionWithdrawing sample devicesColor/spectral properties measurementsInlet valveEngineering

The invention discloses a single-point sampling detection system with micro pressure, which belongs to the technical filed of sampling device. The detection system is characterized in that: the inletend of a conveying tube (10) is communicated with the outlet end of the conveying tube, and the outlet end of the conveying tube (10) is connected in series with a color-comparison tube (7) and is communicated with an adsorption tank (9). The inlet end of a return tube (26) is communicated with the outlet end of the conveying tube (10), and the outlet end of the return tube (26) is communicated with an inlet tube. A sampling check valve (22) is provided between the conveying tube (10) and the inlet tube. A return check valve (23) is provided on the return tube (26). A sampling valve (5) is provided between the conveying tube (10) and the color-comparison tube (7). The inlet tube is provided with an inlet valve (1). A pressure boosting device is provided between the conveying tube (10) andthe inlet tube. According to the single-point sampling detection system with the micro pressure, samples taken by the single-point sampling detection system with the micro pressure are representativeand easy to operate during sampling; and medium leakage during sampling and pollution to the environment are avoided, thereby having a wide application range.

Owner:淄博绿丁环保设备技术有限公司 +1

Three-way discharging ball valve

InactiveCN102889401BReduced service lifeReduce in quantityMultiple way valvesUltimate tensile strengthBall valve

Owner:HUNAN ZHONGXIN EQUIP MFG

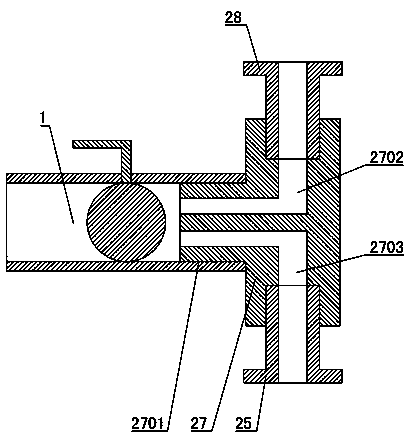

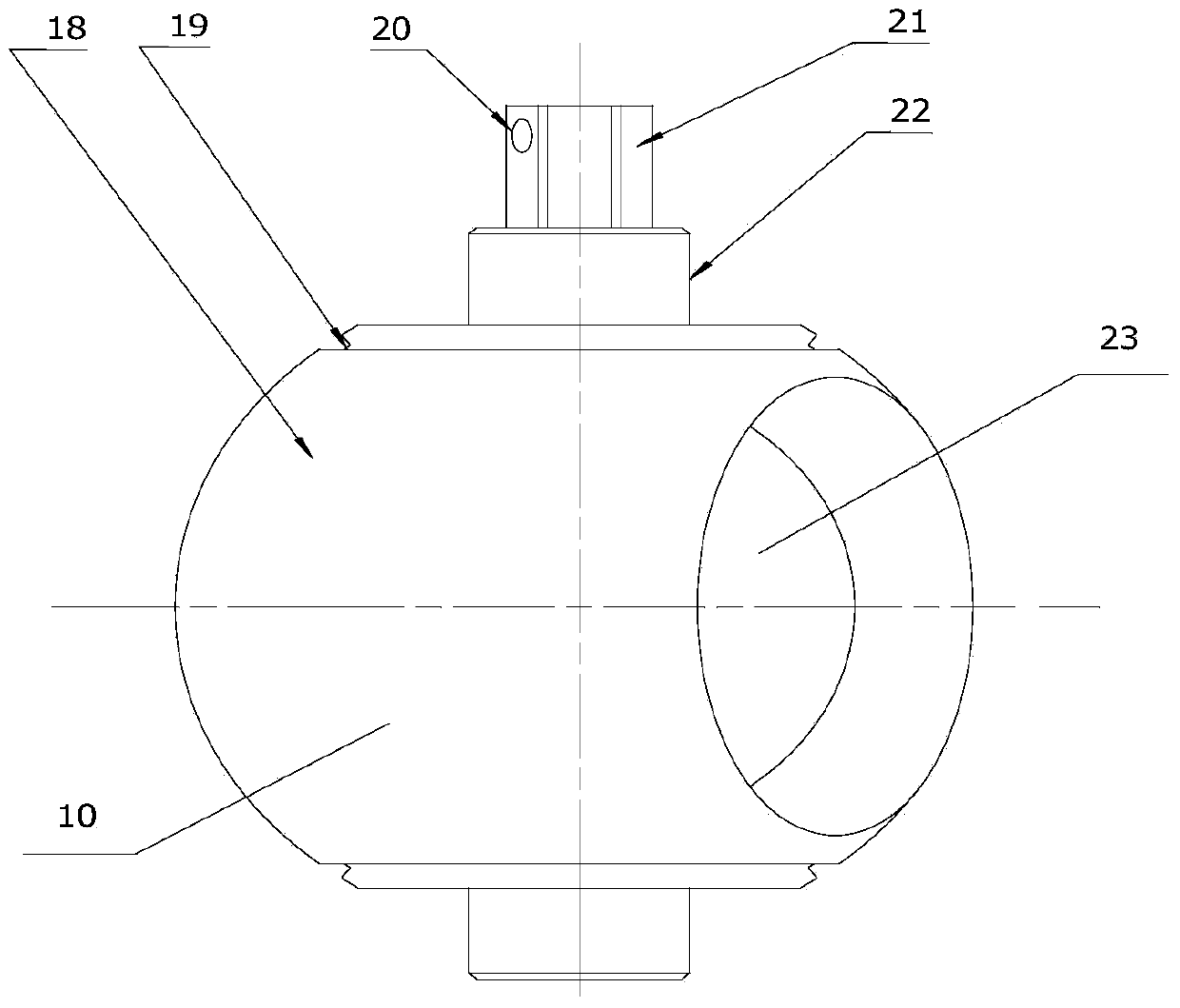

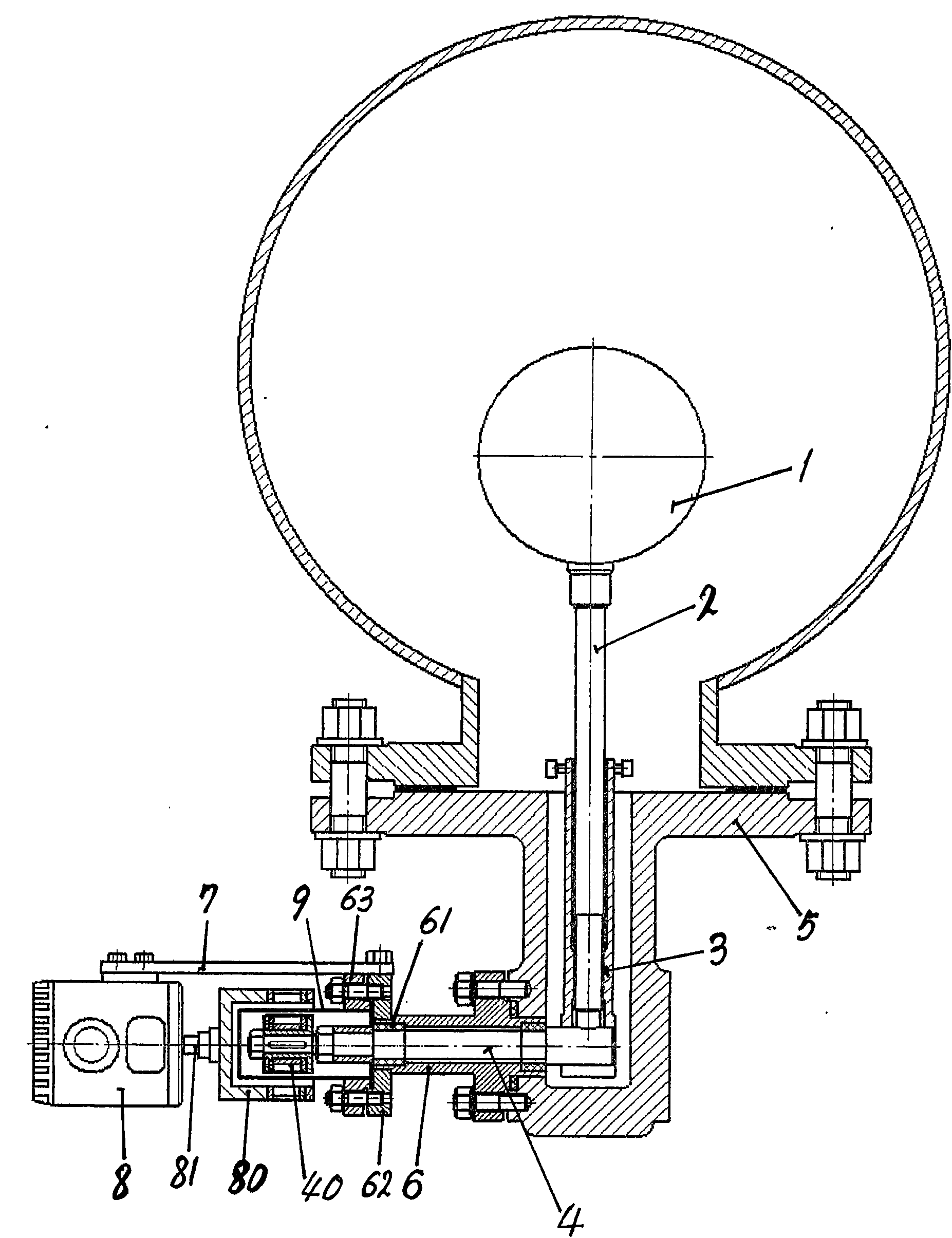

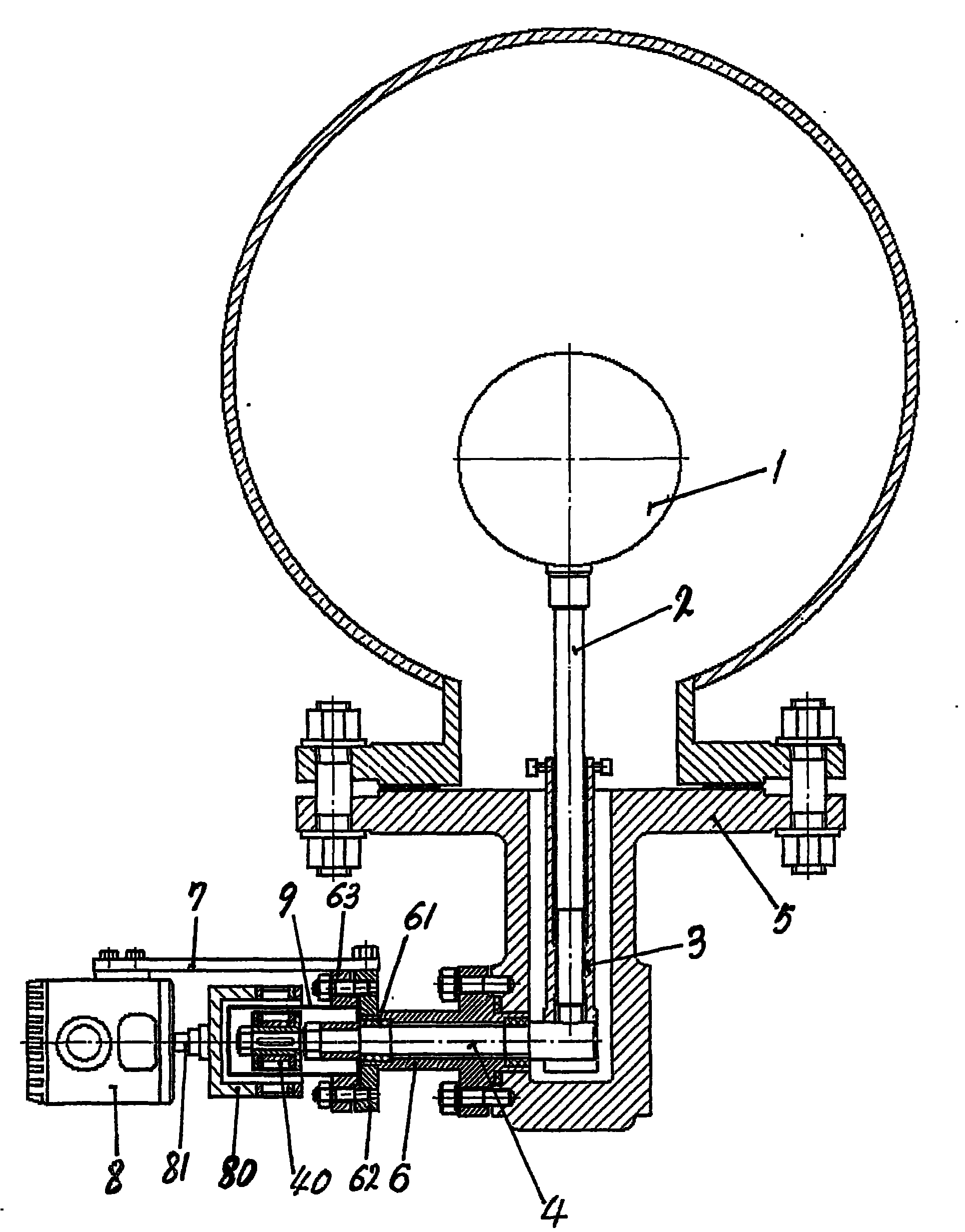

Rotating shaft magnetic coupling type inner float ball level gauge

InactiveCN102003991AGuaranteed rotational flexibilityAvoid the 'locking' phenomenonLevel indicators by floatsCouplingEngineering

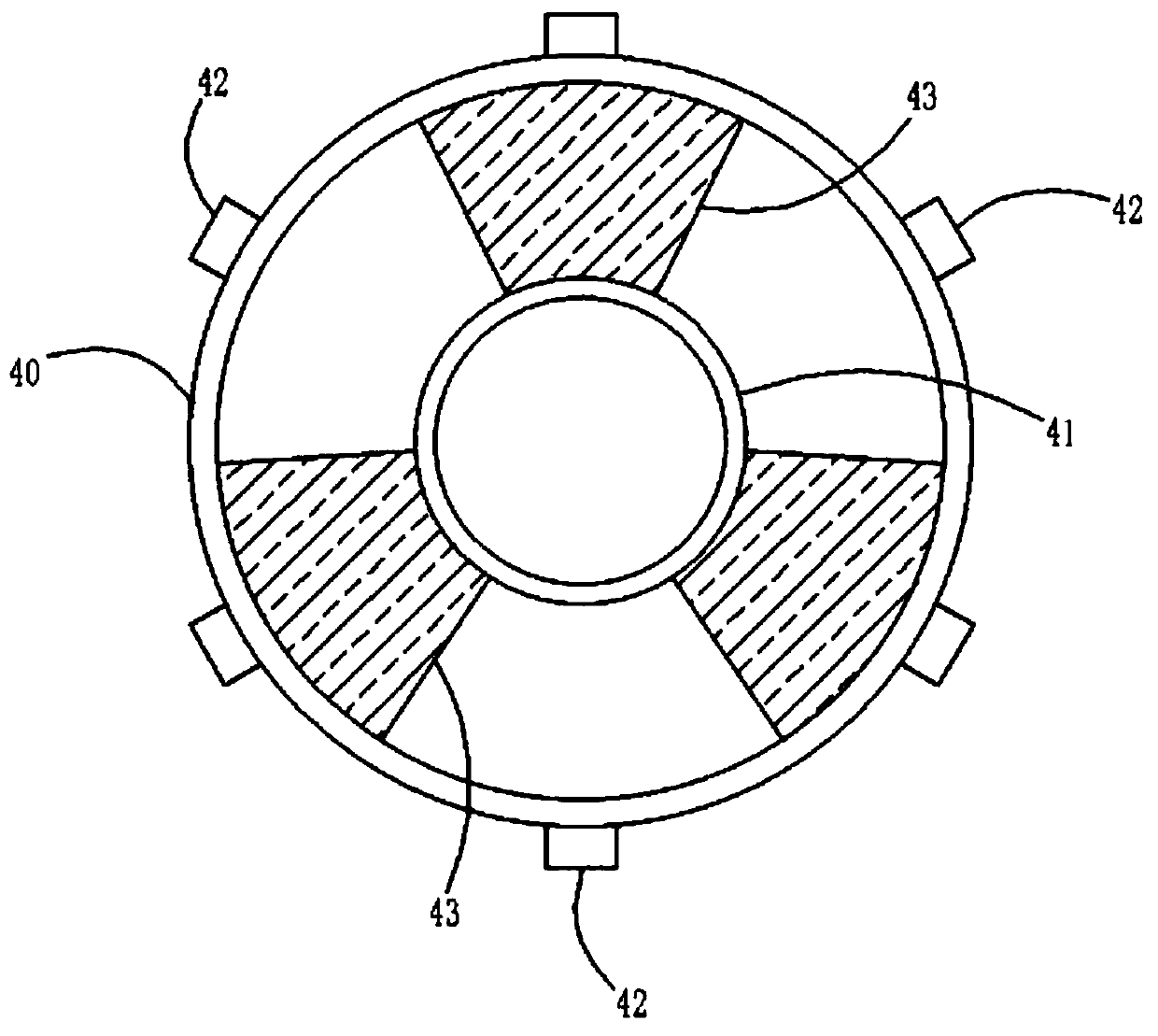

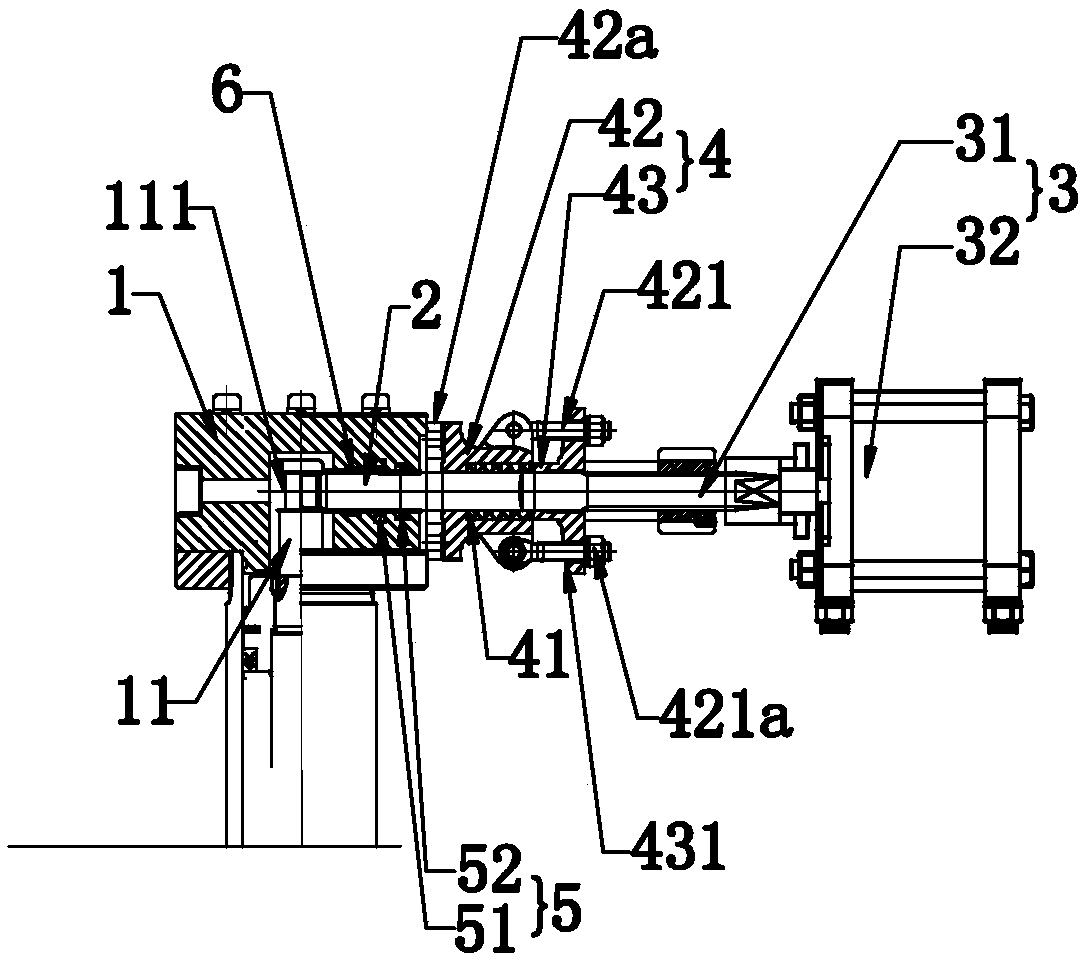

The invention relates to a rotating shaft magnetic coupling type inner float ball level gauge, which comprises a float ball (1), a ball rod (2), a ball rod sleeve (3), a rotating shaft (4), a connecting flange (5), a shaft sleeve (6), a connecting frame (7) and a transmitter (8). The rotating shaft magnetic coupling type inner float ball level gauge is characterized in that an inner magnetic rotor (40) installed on the end of the rotating shaft (4) and an outer magnetic rotor (80) installed on the end of an input shaft of the transmitter rotate in a magnetic coupling type, an isolating sleeve (9) arranged between the inner magnetic rotor (40) and the outer magnetic rotor (80) and an end flange of the shaft sleeve (6) are connected in a sealed and fixed mode. The rotating shaft (4) has flexible rotation and the rotating shaft magnetic coupling type inner float ball level gauge has good sealing performance, good use reliability and good safety and is convenient to install.

Owner:DANDONG TOP ELECTRONICS INSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com