Hydraulic cylinder self-locking mechanical mechanism for cleaning container and self-locking method of hydraulic cylinder self-locking mechanical mechanism

A technology of mechanical mechanism and hydraulic cylinder, applied in the field of self-locking equipment, can solve problems such as poor sealing, and achieve the effects of improving sealing, avoiding leakage and enhancing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

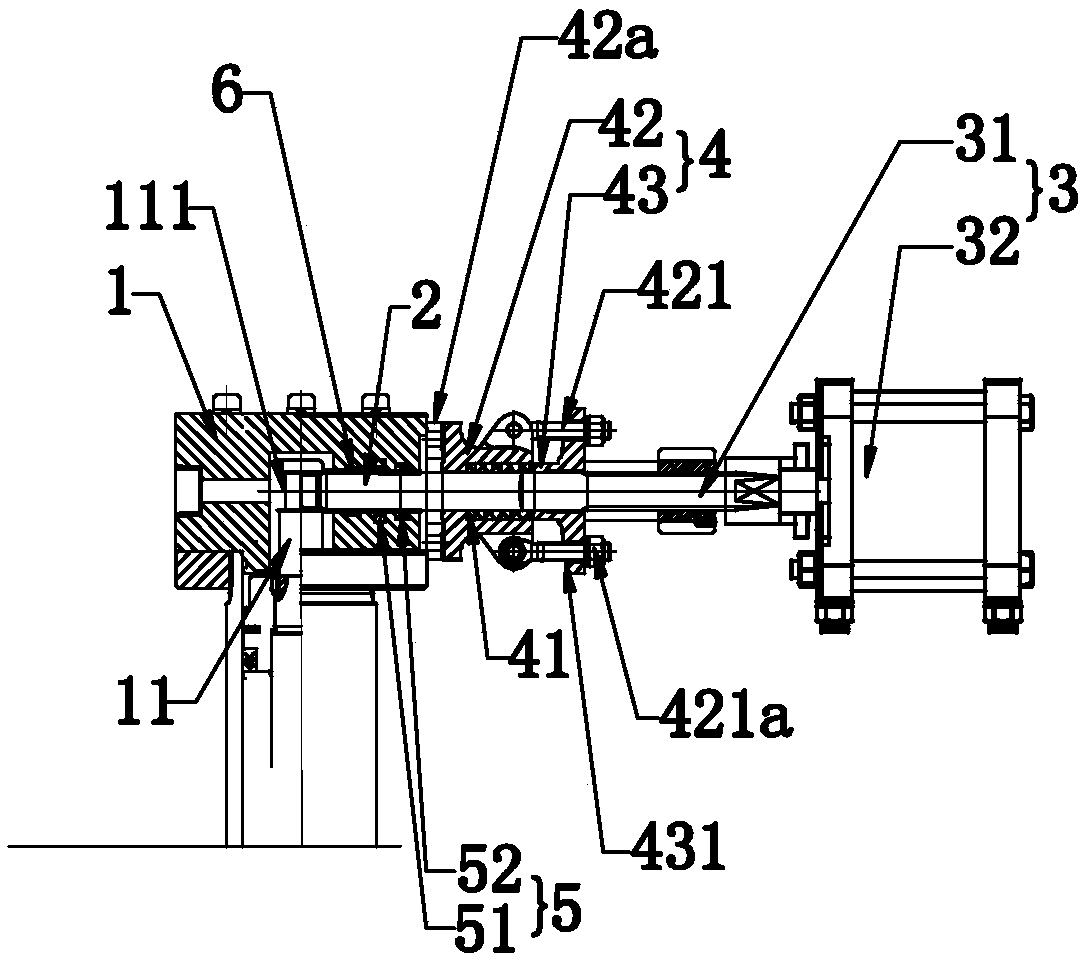

[0025] Such as figure 1 As shown, the present invention discloses a hydraulic cylinder self-locking mechanical mechanism for container cleaning, including a hydraulic cylinder block 1 and a piston 11 arranged inside the hydraulic cylinder block 1, and in a specific embodiment of the present invention, includes a hydraulic cylinder The latch groove 111 on 11, one end penetrates the inside of the hydraulic cylinder block 1 and can penetrate the self-locking pin 2 in the latch groove 111, the driving assembly 3 for driving the self-locking pin 2 to slide axially in the latch groove 111, and The closed packing mechanism 4 on the drive assembly 3 and the packing 41 located in the closed packing mechanism 4; when the closed packing mechanism 4 works, the packing 41 enters the gap between the self-locking pin 2 and the hydraulic cylinder block 1 The gap and / or the gap between the closed packing mechanism 4 and the drive assembly 3 completes the sealing of the hydraulic cylinder block...

Embodiment 2

[0039] Embodiment 2, the difference with embodiment 1 is

[0040] In a specific embodiment of the present invention, the valve stem 31 can be fixedly connected with the packing gland 43 .

[0041] By adopting the above technical scheme: when the cylinder controls the self-locking pin to enter the pin groove through the valve stem, the packing gland can be controlled synchronously to squeeze the packing, and when the self-locking pin completes the self-locking of the piston, the hydraulic cylinder can be completed in time. The sealing of the body, so as to further improve the sealing performance when self-locking, and further avoid leakage when the hydraulic cylinder is self-locking, and enhance the safety during use.

Embodiment 3

[0042] Embodiment 3, the difference with embodiment 1 is

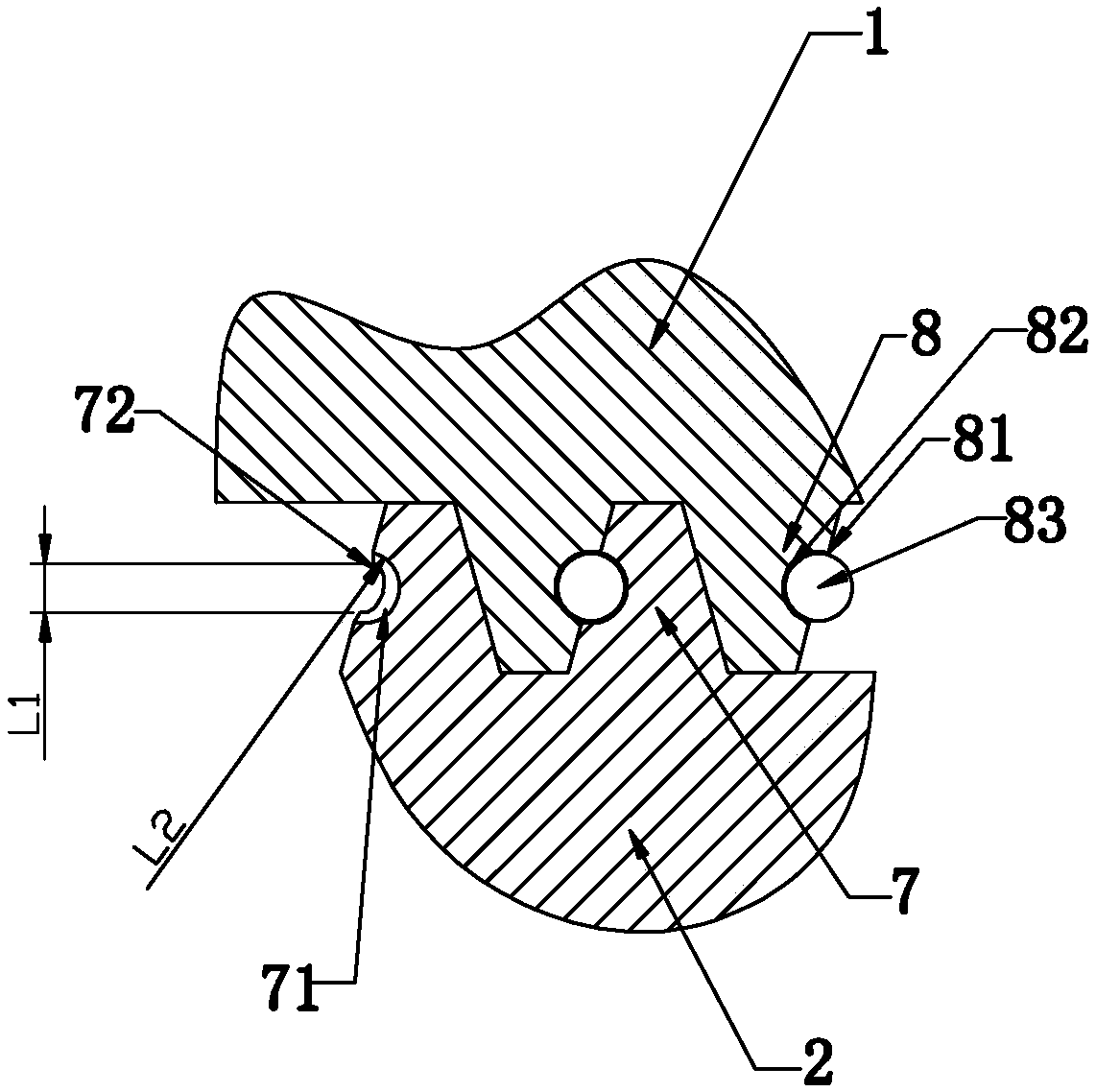

[0043] Such as figure 2 As shown, in a specific embodiment of the present invention, the outer wall of the self-locking pin 2 is provided with an external thread 7, and the contact surface between the hydraulic cylinder body 1 and the self-locking pin 2 is provided with a thread that is compatible with the external thread 7. The internal thread 8 of the internal thread 8 is provided with a plurality of first grooves 81 at intervals on the tooth wall of the thread of the internal thread 8, and the groove bottom of each first groove 81 is fixedly connected with the first groove through a compression element 82 The diameter of the ball 81 matches the ball 83, and the ball 83 is partially exposed outside the first groove 81. The thread of the external thread 7 is provided with a plurality of second grooves 71 that are compatible with each ball 83. The adjacent second grooves 71 communicate with each other through the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com