Production method of pipeline compensator

A technology of pipeline compensator and production method, which is applied in the direction of pipe components, engine seals, pipes/pipe joints/pipe fittings, etc., which can solve the problems of reducing the service life of compensators, increasing pipeline maintenance costs, and lack of elasticity, so as to improve the use of Longer service life, avoid medium leakage, and reduce maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

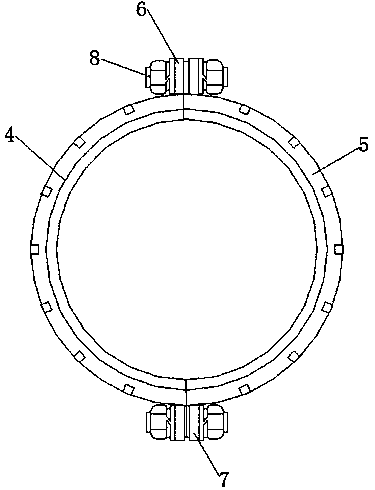

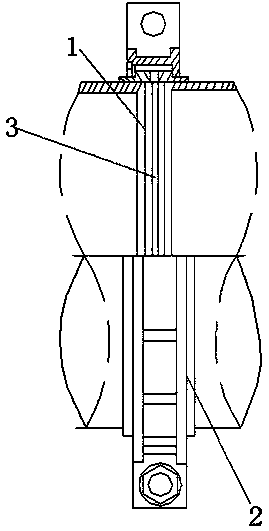

[0011] As shown in Figure 1 and Figure 2, a production method of a pipeline compensator includes a circular collar body 2 with a circular groove 1, a sealing ring 3 is arranged in the circular groove 1, and the circular The collar body 2 is composed of a first arc-shaped pressure ring 4 and a second arc-shaped pressure ring 5; in this embodiment, the compensator is installed in the pipeline, so as to utilize the two The telescopic tube at the end makes axial displacement and angular displacement to absorb multi-dimensional deformation. Among them, the self-tightening force of the sealing ring and the medium force are used for sealing to improve the sealing performance and avoid leakage.

[0012] The upper connection seat 6 and the lower connection seat 7 are respectively provided at the joints of the first arc-shaped pressure ring 4 and the two ends of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com