Heating device and method for closed type towing chain heat preservation

A heating device and heating method technology, applied in tow chains, heat storage heaters, fluid heaters, etc., can solve the hidden dangers of cable power consumption, platform equipment and personnel safety, affect the emergency flushing use of on-site operators, and affect drilling and repairing. Well operation efficiency and other issues, to avoid medium leakage, avoid local overheating or subcooling, and avoid drilling downtime for maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further elaborated below according to specific embodiments.

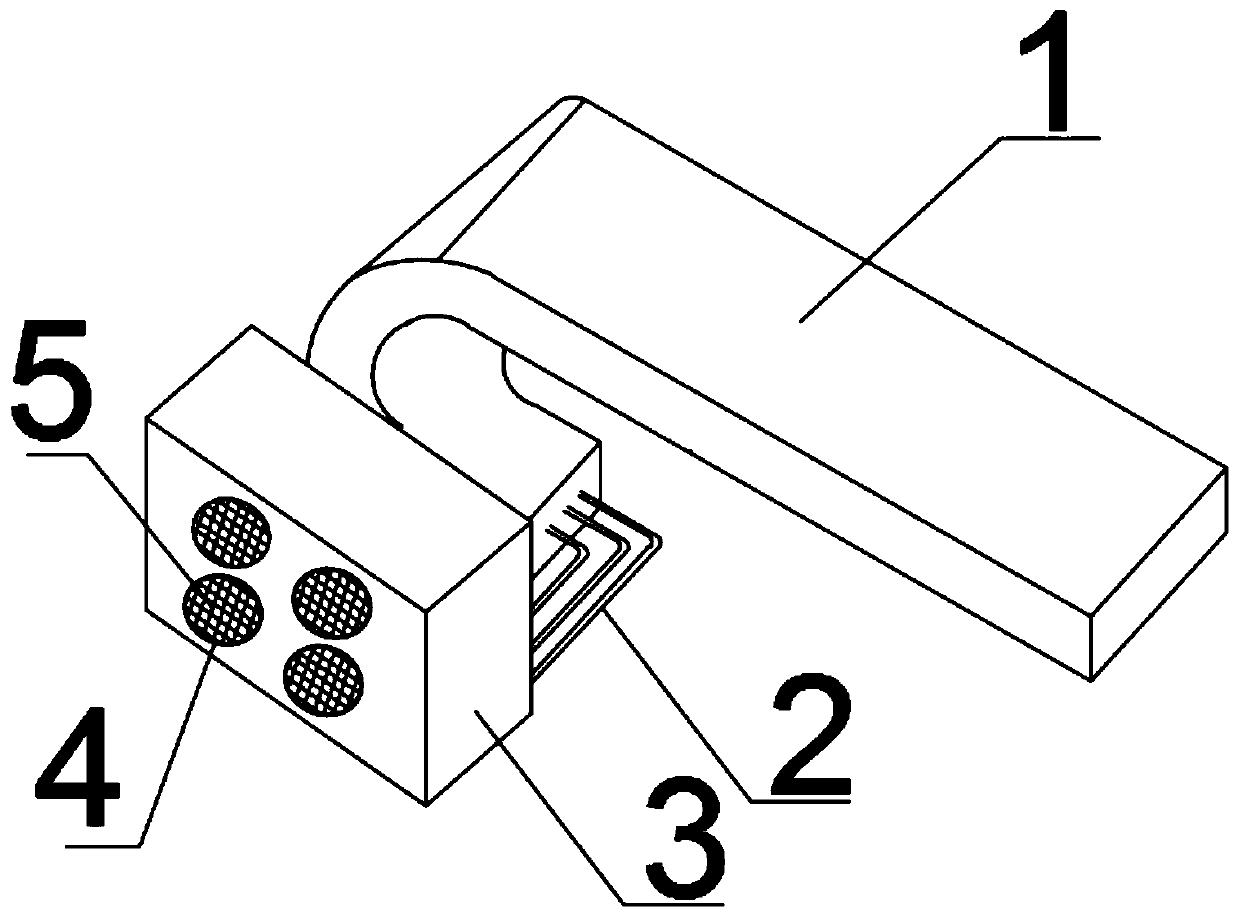

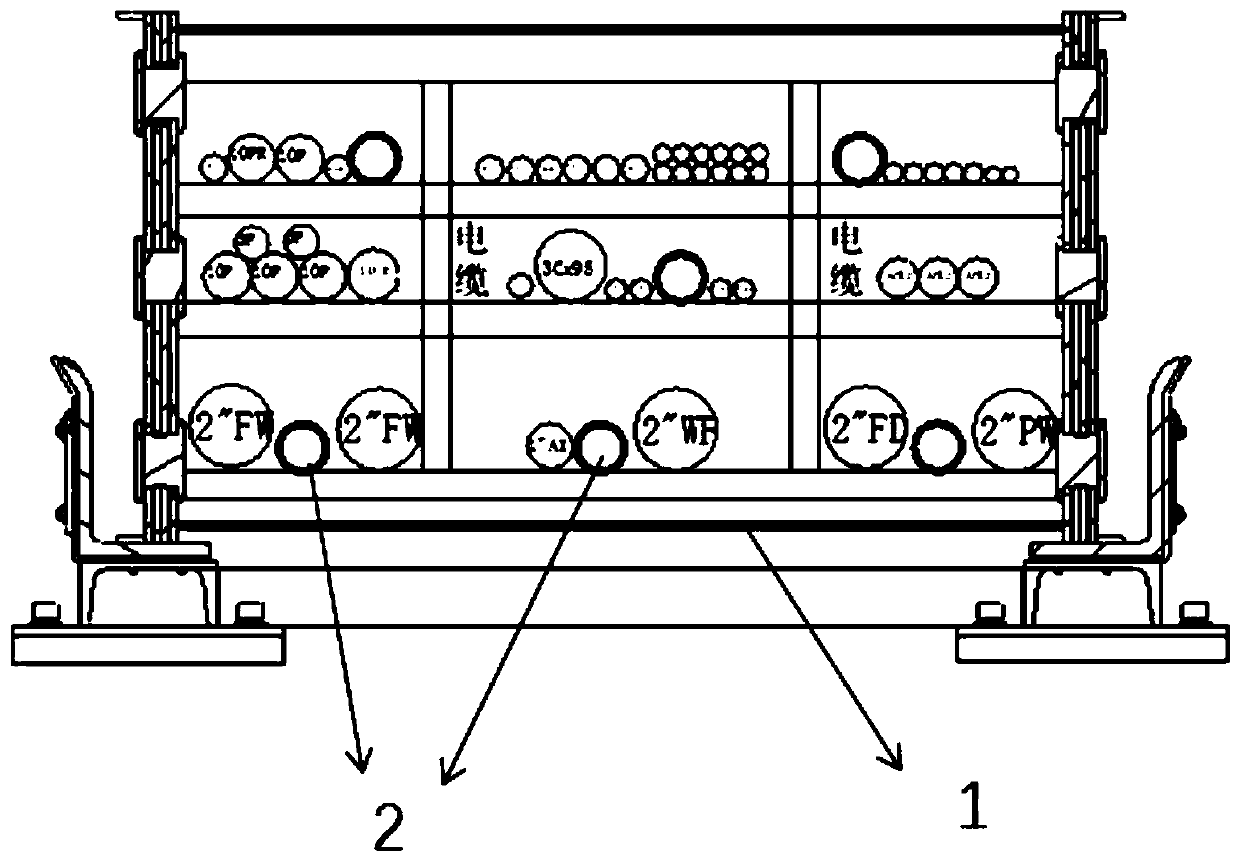

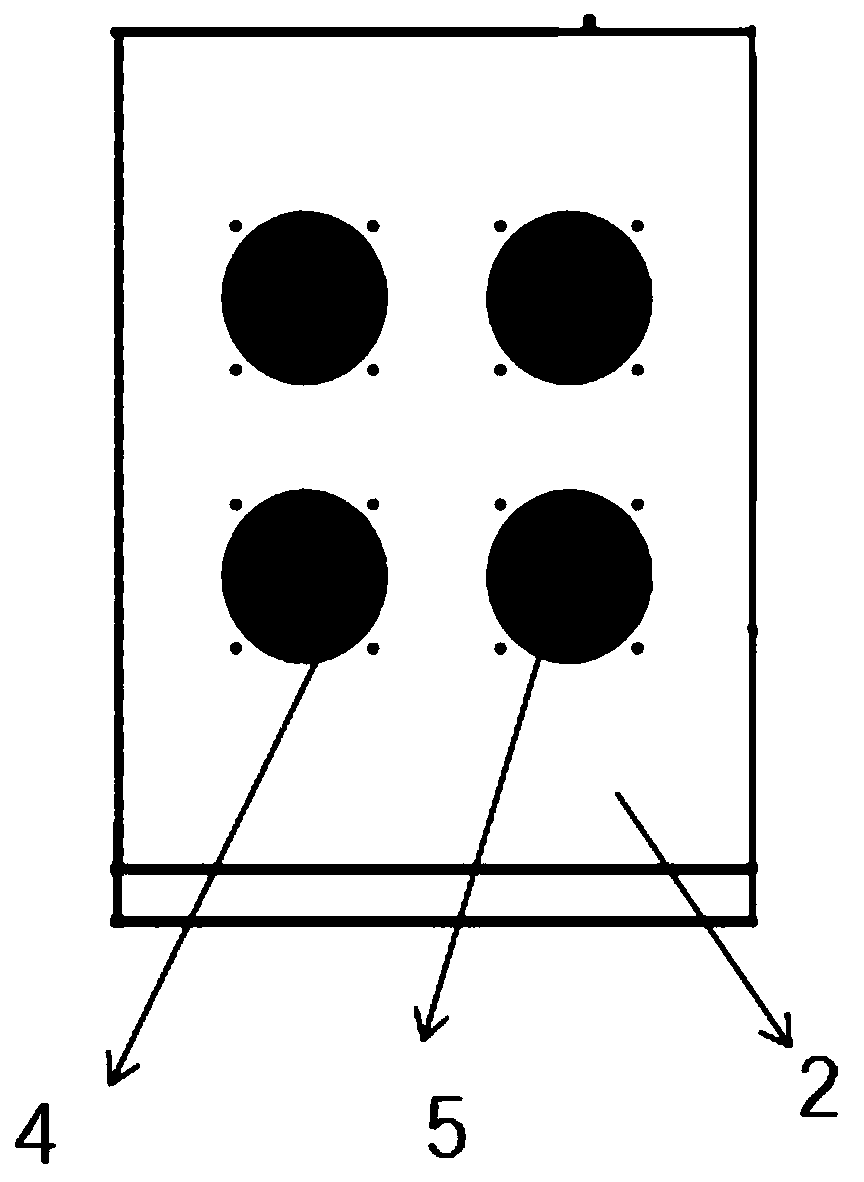

[0033] Such as Figure 1-4 The shown heating device for closed drag chain insulation includes a heater 3, a fan connected to a power supply and an electric heater are arranged in the heater 3, and an air inlet 4 is arranged on the air inlet side of the heater 3, The air inlet 4 is provided with a guard net 5 . The air outlet side of the heater 3 is provided with an air outlet 6, and the air outlet 6 is connected with a heating pipe 2, and the end of the air outlet pipe 7 is sealed and connected with the inlet end of the heating pipe 2, and the heating pipe 2 runs through the closed thermal insulation drag chain, and the heating pipe 2 is provided with cooling holes. The cooling holes are arranged at equal intervals on the heating tube 2 . In this embodiment, the number of air inlets 4 is four, and the positions of the four air inlets 4 form four corners of a rectangle; the num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com