A micro-pressure single-point sampling detection system

A detection system, single-point technology, applied in the direction of sampling device, color/spectral characteristic measurement, etc., can solve the problems of physical health violations of sampling employees, difficulty in guaranteeing the samples taken, and non-representative samples, etc., to achieve convenient operation, Easy to install, easy to press and fix the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

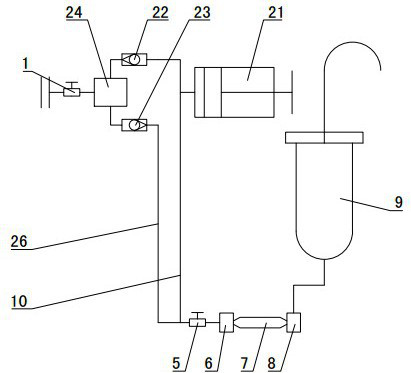

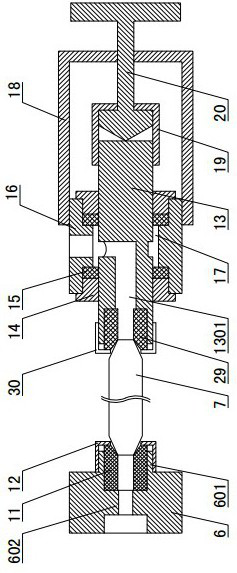

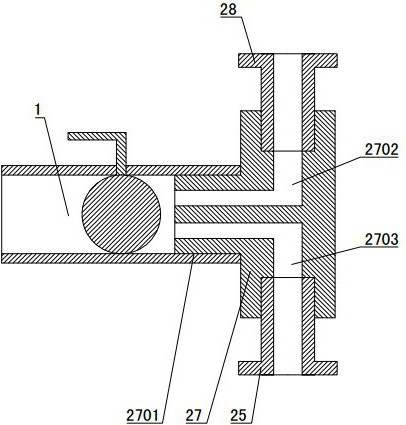

[0032] Such as figure 1 As shown: the output end of the input pipe is connected with a medium communication block 24 . In this embodiment, the pressurization device is a manual pump 21, and the pressurization device may also be a delivery pump. The manual pump 21 communicates with the input pipe through a medium communication block 24 , and a sampling check valve 22 is provided between the manual pump 21 and the medium communication block 24 to allow the medium to flow to the manual pump 21 . The delivery pipe 10 is connected to the output end of the manual pump 21 , and the input end of the delivery pipe 10 is communicated with the manual pump 21 . The output end of delivery pipe 10 is connected with colorimetric tube 7 through support block 6, is provided with sampling valve 5 between the output end of delivery pipe 10 and support block 6, and the output end of delivery pipe 10 is also connected with return pipe 26, and return pipe 26 The input end of the return pipe 10 is...

Embodiment 2

[0047] Such as Figure 4 Shown: the difference between embodiment 2 and embodiment 1 is: the differential pressure sampling detection system includes quantitative tank 2, colorimetric tube 7 and adsorption tank 9, the input end of quantitative tank 2 is connected with input valve 1, colorimetric tube 7 The input end of the colorimetric tube 7 is connected with the output end of the quantitative tank 2, the output end of the colorimetric tube 7 is connected with the adsorption tank 9, a sampling valve 5 is arranged between the colorimetric tube 7 and the quantitative tank 2, and the output end of the quantitative tank 2 is also connected There is an output valve 4, the two ends of the colorimetric tube 7 are respectively provided with a support block 6 and a fastening block 8, the colorimetric tube 7 is arranged between the support block 6 and the fastening block 8, and the fastening block 8 is connected with a push fastening Block 8 compresses the pressing mechanism of colorim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com