Welding neck flange with assembling ring preset at neck opening and implementation method of welding neck flange

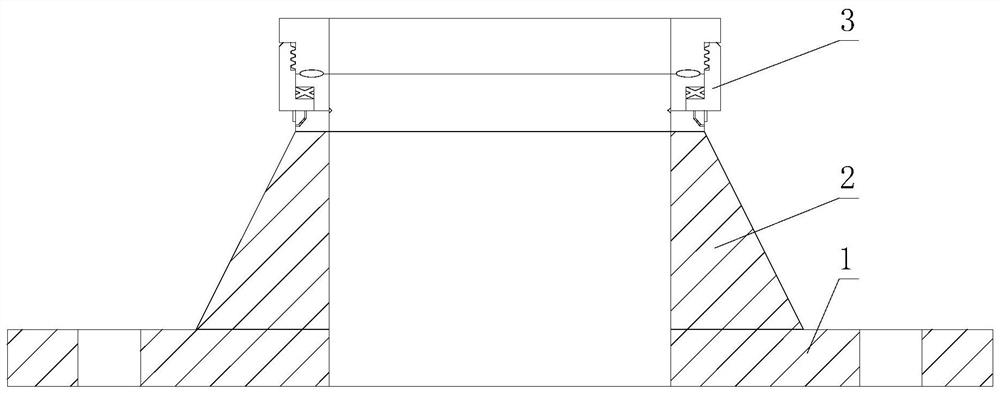

A technology for assembling rings and welding flanges. It is used in flange connections, mechanical equipment, pipes/pipe joints/fittings, etc., and can solve problems that affect practicality, fail to solve disassembly and assembly, and difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] A method for implementing a butt welding flange with a preset assembly ring at the neck, comprising the following steps:

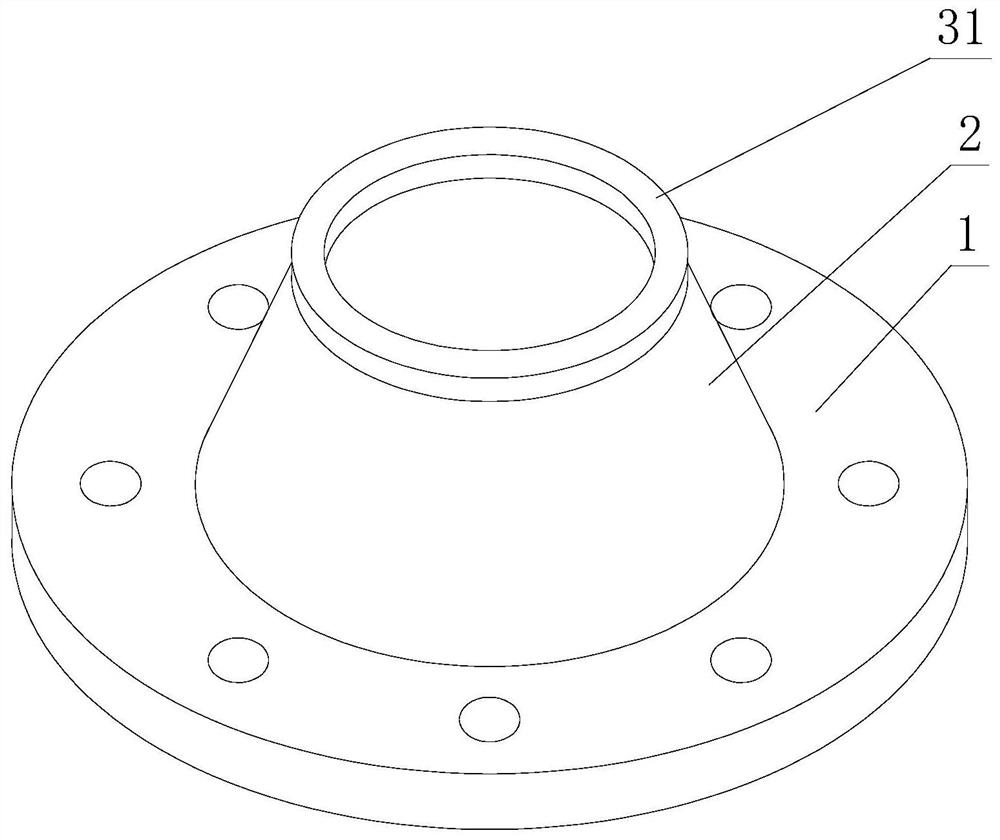

[0038] Step 1: first weld and fix the bottom ring 31 on the top of the flange neck 2, wherein the flange neck 2 has been connected with the flange main body 1;

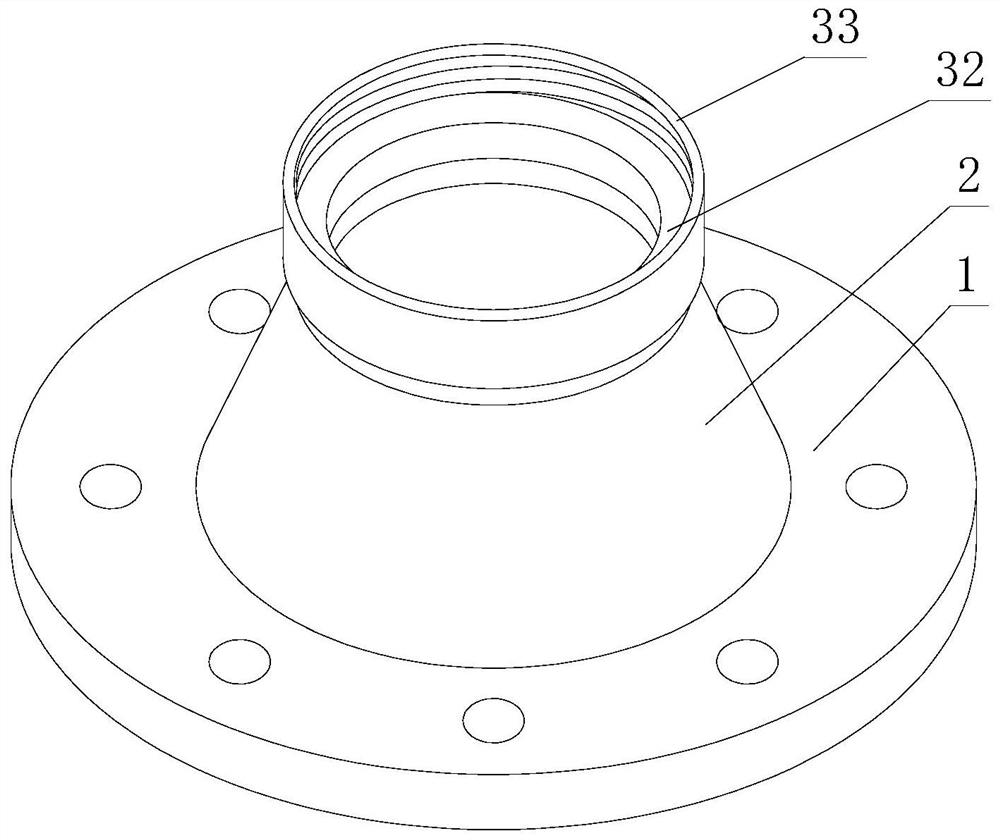

[0039] Second step: then put the upper ring 33 on the outer edge of the upper surface of the bottom ring 31, and then evenly arrange the deformation block 35 on the edge of the inner cavity of the upper ring 33, at this time, the sealing ring 34 is in contact with the outer wall of the bottom ring 31 snapping, then the middle ring 32 is placed on the inner edge of the upper surface of the bottom ring 31, and the middle ring 32 and the bottom ring 31 are welded together;

[0040] Step 3: align the basic welding ring 36 with the welding position to be connected, and then weld the basic welding ring 36 on the welding position by welding;

[0041] The fourth step: then preset the rubber sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com