Rotating shaft magnetic coupling type inner float ball level gauge

A floating ball liquid level and rotating shaft technology, applied in the direction of buoy liquid level indicator, etc., can solve the problems of unreliability, poor sealing, leakage of medium liquid, etc., to ensure reliability and safety, and ensure flexible rotation performance, to avoid the effect of medium leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

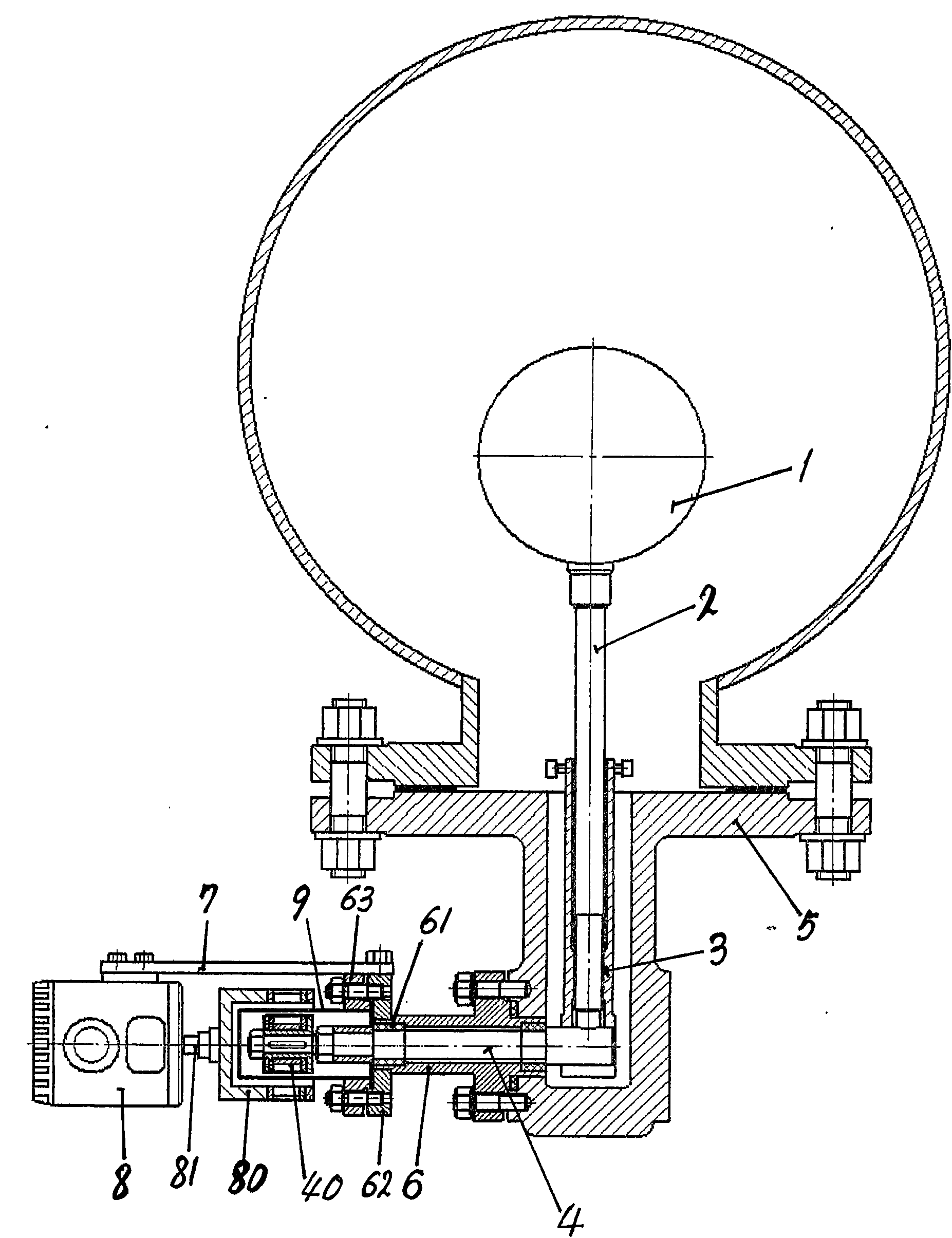

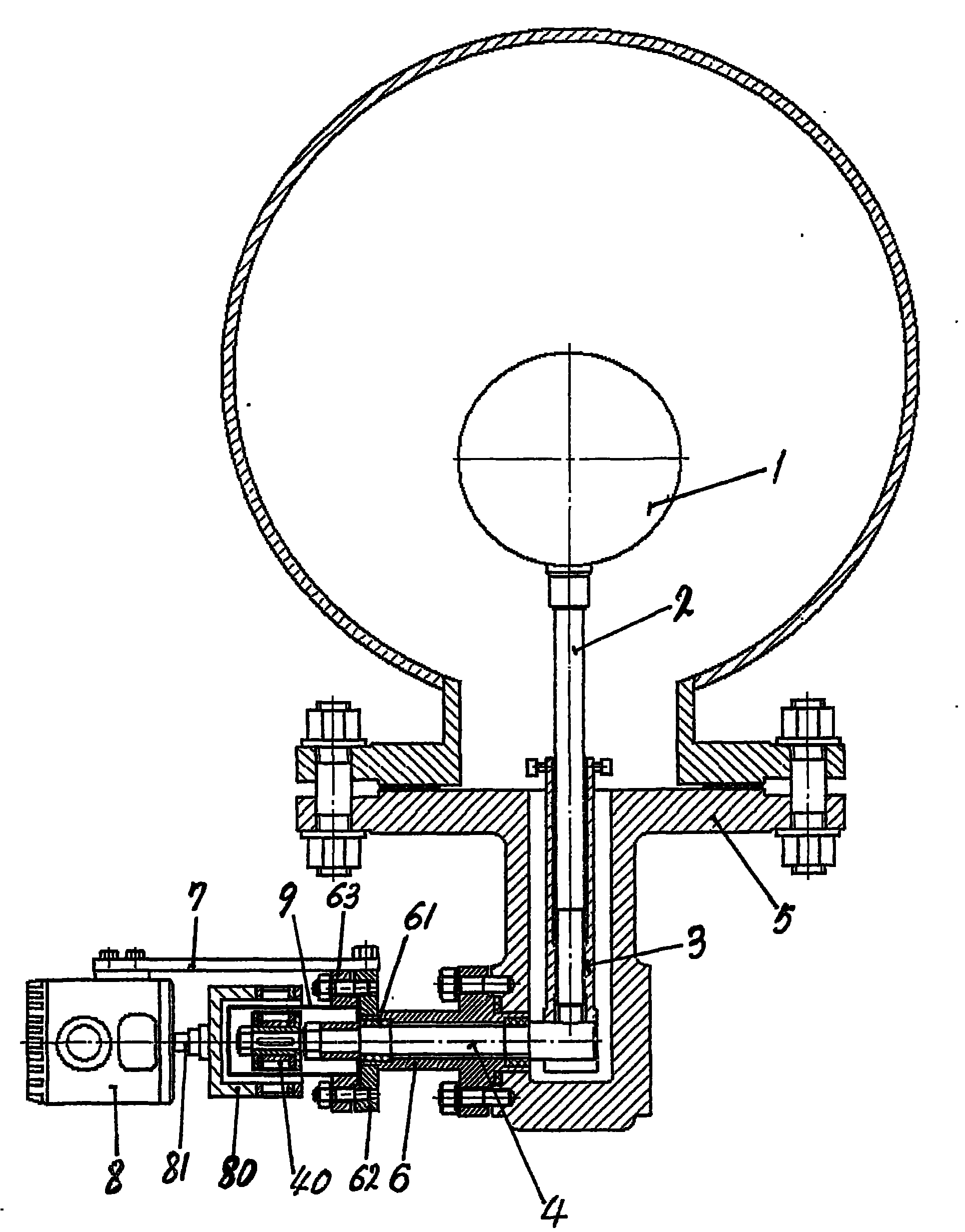

[0007] The present invention includes a float 1, a club 2, a club sleeve 3, a rotating shaft 4, a connecting flange 5, a shaft sleeve 6, a connecting frame 7, and a transmitter 8, and the rotating shaft 4 and the shaft sleeve 6 pass through a sliding bearing 61 Installed in rotation, the inner magnetic rotor 40 is installed on the shaft end of the rotating shaft 4, and the outer magnetic rotor 80 is installed on the shaft end of the input shaft 81 of the transmitter 8. The inner magnetic rotor 40 and the outer magnetic rotor 80 are mutually Cooperating with the magnetic coupling transmission, a spacer 9 is provided between the inner magnetic rotor 40 and the outer magnetic rotor 80, and the spacer 9 and the end flange 62 of the shaft sleeve 6 are sealed and fixedly connected by the pressure plate 63, the gasket and the fastening bolt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com