Three-way discharging ball valve

A material ball and three-way technology, which is applied in the field of three-way unloading ball valves, can solve problems such as poor sealing of ram structure valves, endangering the health of operators, and polluting the operating environment, so as to prevent medium leakage, reduce labor intensity, The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

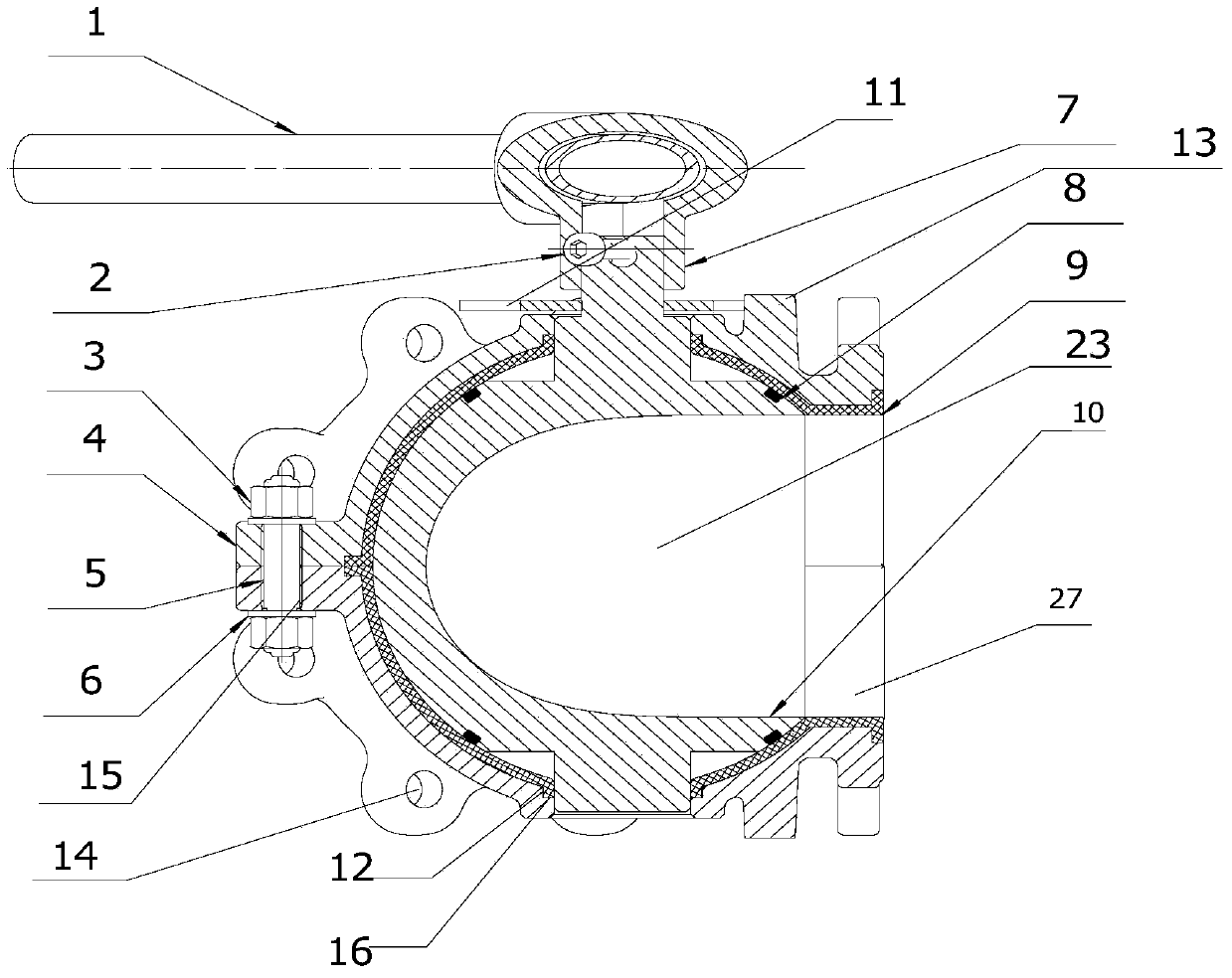

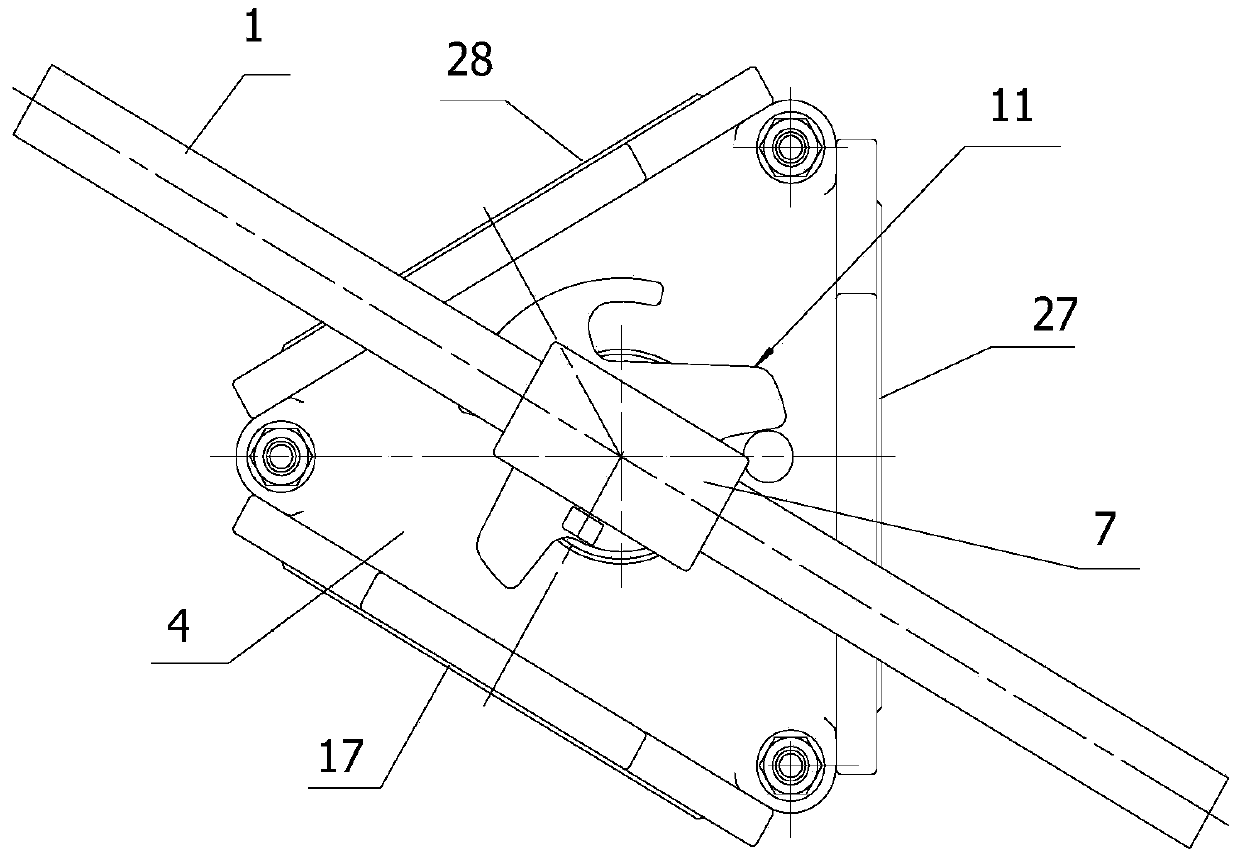

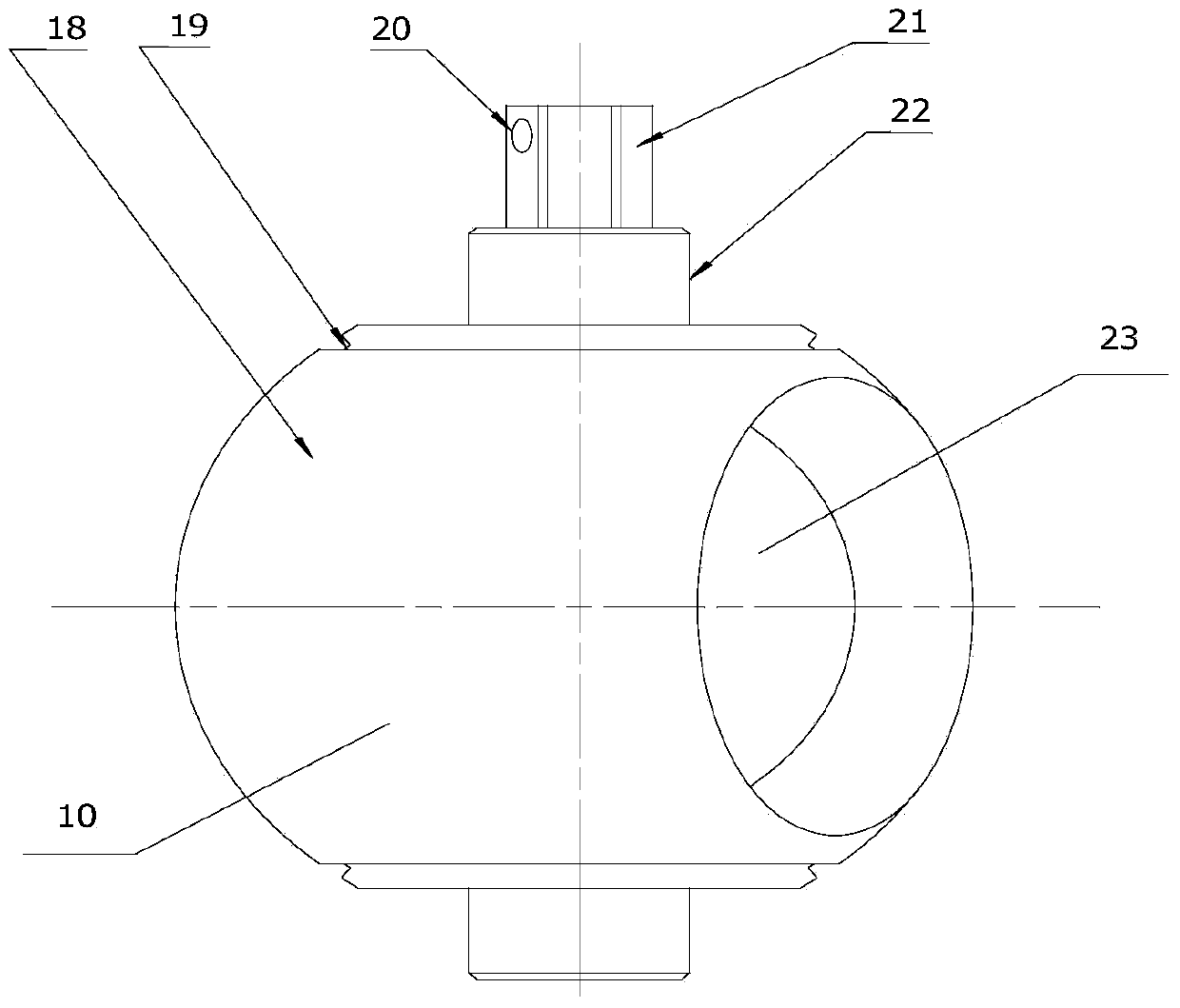

[0027] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 , the valve body 4 is composed of two parts, arranged symmetrically up and down, and cast with metal or high-strength plastic; the screw rod 5 passes through the positioning hole 15 on the valve body 4, and is locked with the nut 3 and the gasket 6 to form a three-way spherical shell , the valve body 4 is provided with an inlet 27, a first outlet 28, and a second outlet 17, the angle between the first outlet 28 and the second outlet 17 is 60 to 180 degrees, the inlet 27 and the first outlet 28, the second The outlet 17 is provided with a quincunx flange, and the quincunx flange is provided with a threaded hole 14, which can be used to connect the valve body 4 with the pipeline; the bushing 9 is composed of two pieces, arranged symmetrically up and down, and the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com