Grinding machine for hard seal copper gaskets of check valves

A hard sealing and grinding machine technology, applied in the field of mechanical grinding devices, can solve the problems of micro-leakage of the medium, the fineness does not meet the standard, and it is not easy to operate, and achieves the effect of preventing the micro-leakage of the medium, improving the grinding fineness and improving the work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

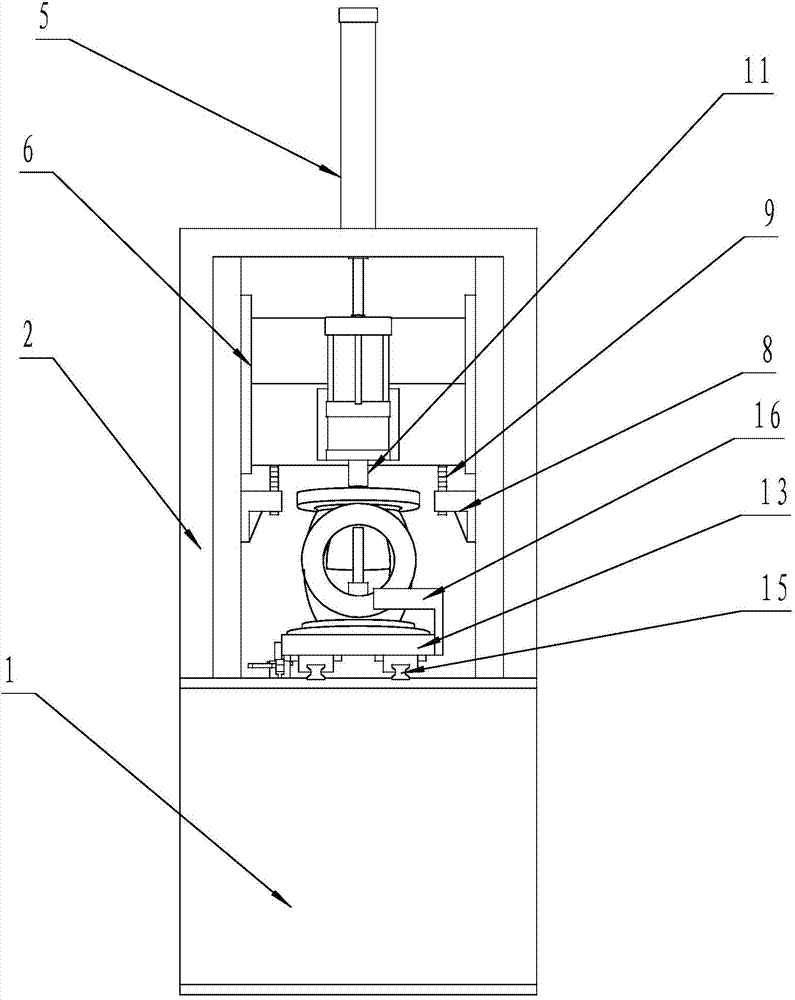

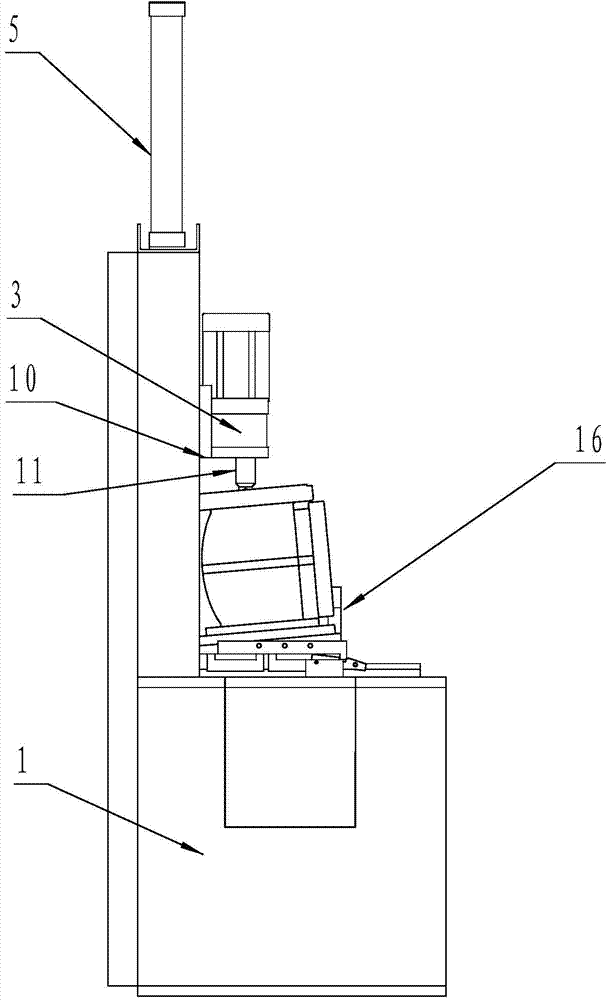

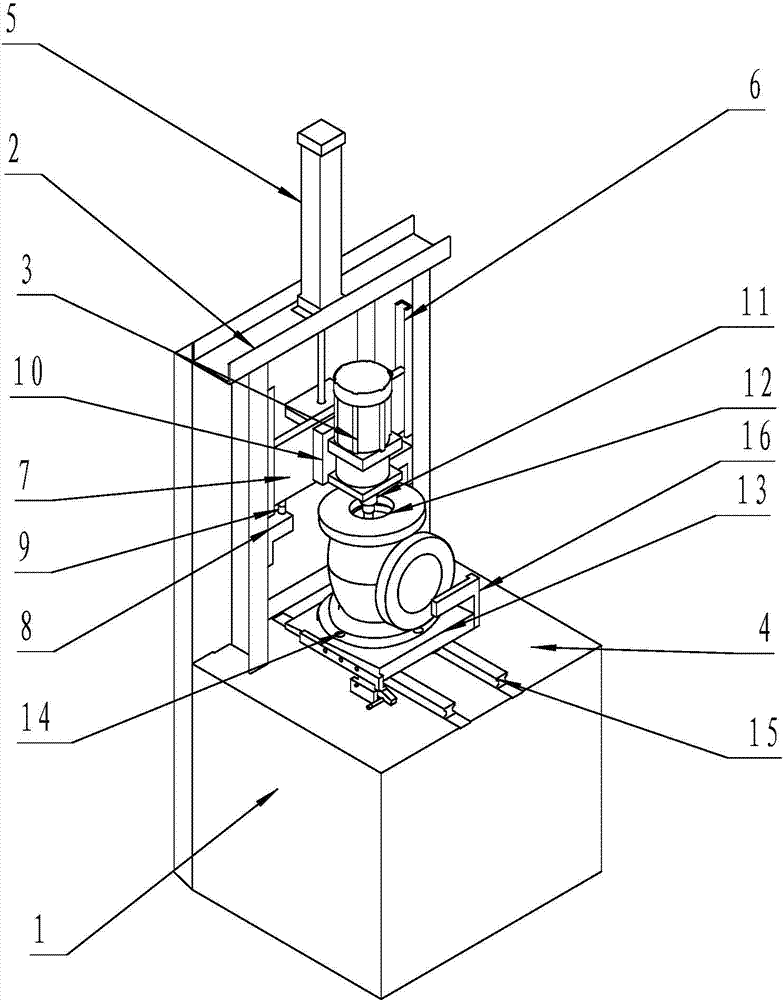

[0021] Such as figure 1 , figure 2 , image 3 As shown, a non-return valve hard-sealed copper pad grinding machine includes a machine base 1, a portal frame 2 composed of columns and beams installed on the machine base 1, and a reducer 3. It is characterized in that it also includes a The hard-sealed copper pad grinding device under the beam of the portal frame 2, the lifting device of the hard-sealed copper pad grinding device and the limit device of the hard-sealed copper pad grinding device, and the check valve installed on the machine base platform 4 of the machine base 1 Body fixing devices and electrical appliances, air pressure control devices;

[0022] The lifting device of the hard-sealed copper pad grinding device includes a telescopic cylinder 5 installed on the crossbeam of the portal frame 2 and a slide rail 6 installed on the column of the portal frame 2, and the push rod of the telescopic cylinder 5 is connected to the speed reducer fixing device , the verti...

Embodiment 2

[0026] Such as figure 1 , figure 2 , image 3 As shown, a non-return valve hard-sealed copper pad grinding machine includes a machine base 1, a portal frame 2 composed of columns and beams installed on the machine base 1, and a reducer 3. It is characterized in that it also includes a The hard-sealed copper pad grinding device under the beam of the portal frame 2, the lifting device of the hard-sealed copper pad grinding device and the limit device of the hard-sealed copper pad grinding device, and the check valve installed on the machine base platform 4 of the machine base 1 Body fixing devices and electrical appliances, air pressure control devices;

[0027] The lifting device of the hard-sealed copper pad grinding device includes a telescopic cylinder 5 installed on the crossbeam of the portal frame 2 and a slide rail 6 installed on the column of the portal frame 2, and the push rod of the telescopic cylinder 5 is connected to the speed reducer fixing device , the verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com