A freeze-drying machine with a plate layer that can be lifted and tilted

A freeze-drying machine and plate layer technology, which is applied in the field of freeze-drying machines, can solve the problems of limited inclination angle of freeze-dried plates, difficult pouring of residual water, complicated transmission structure, etc., so as to reduce friction points of connecting rods and particle pollution. The effect of reducing the risk and simplifying the transmission structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

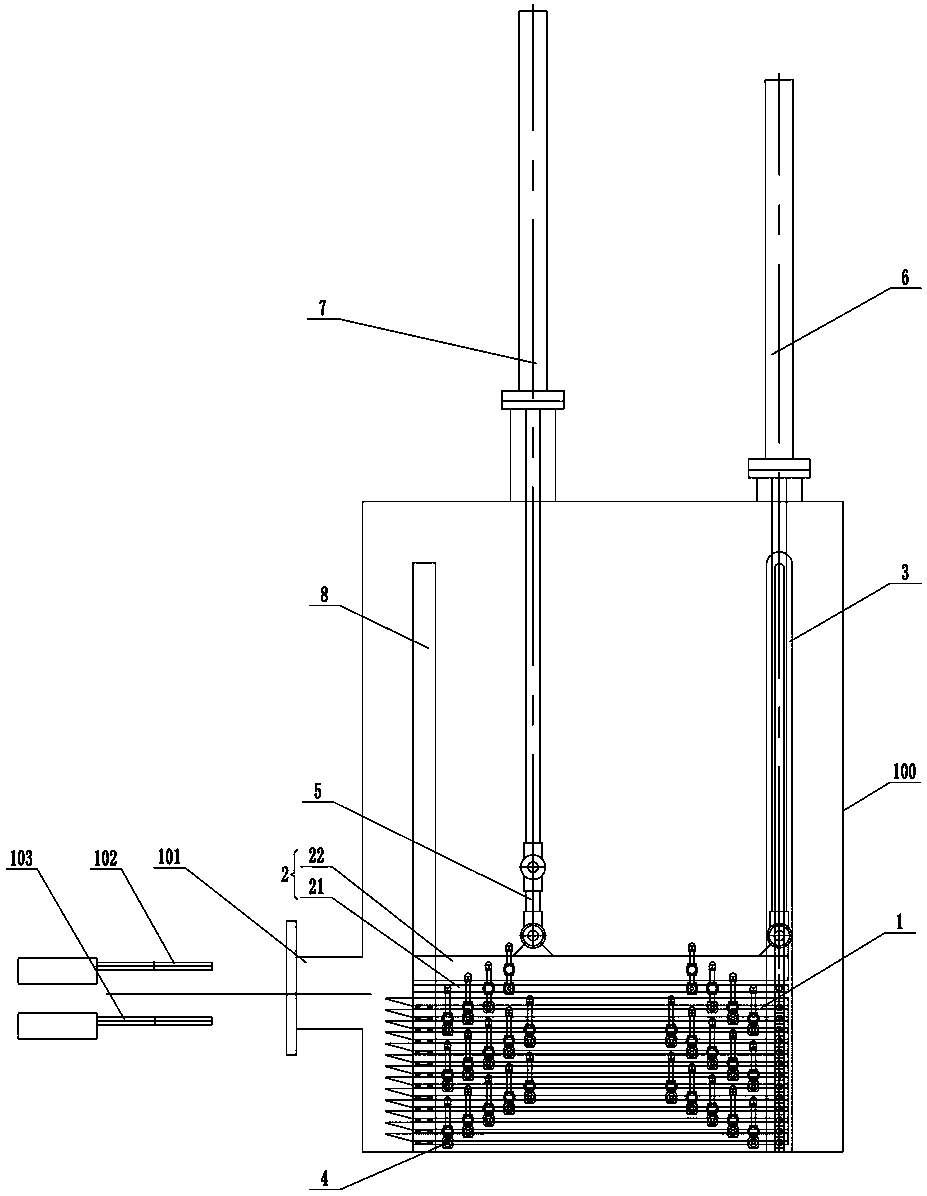

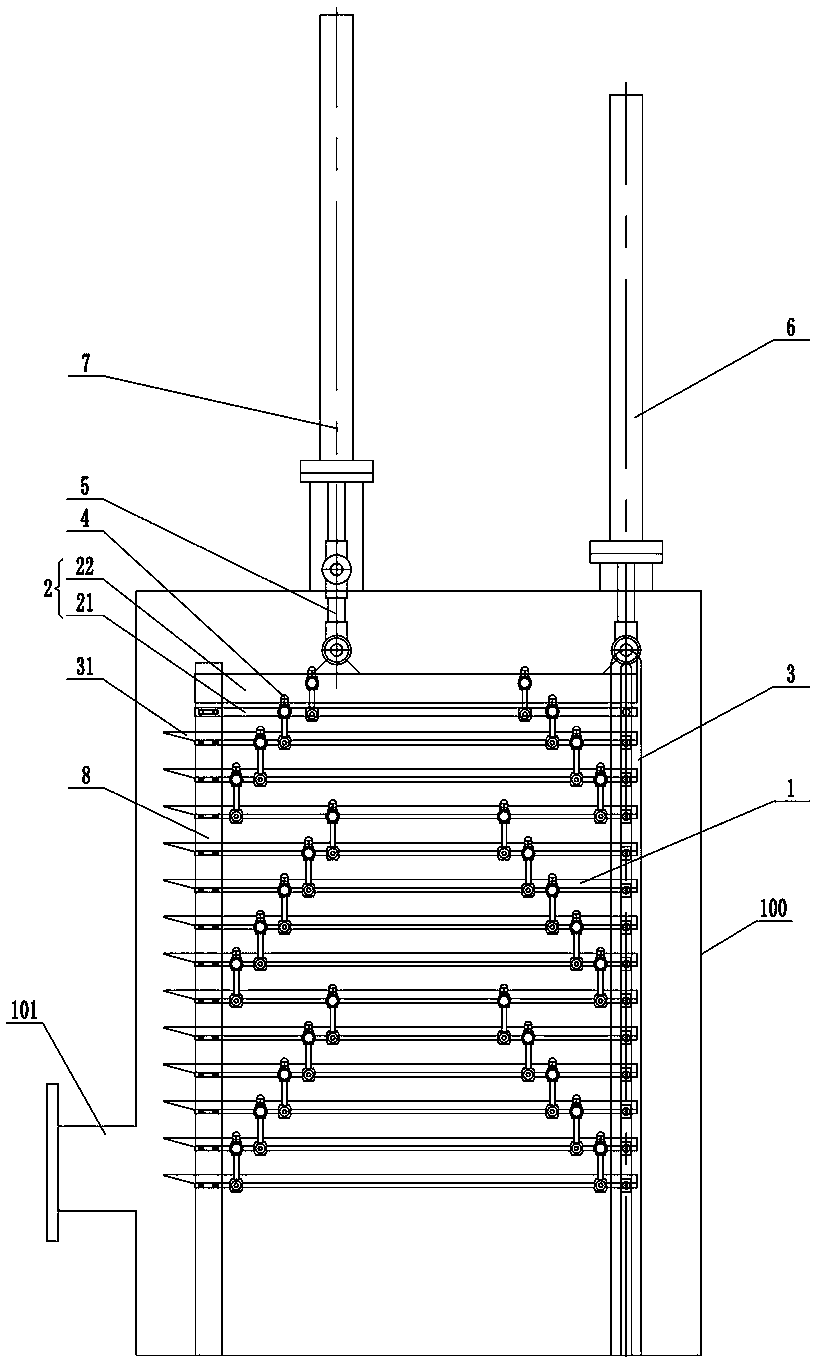

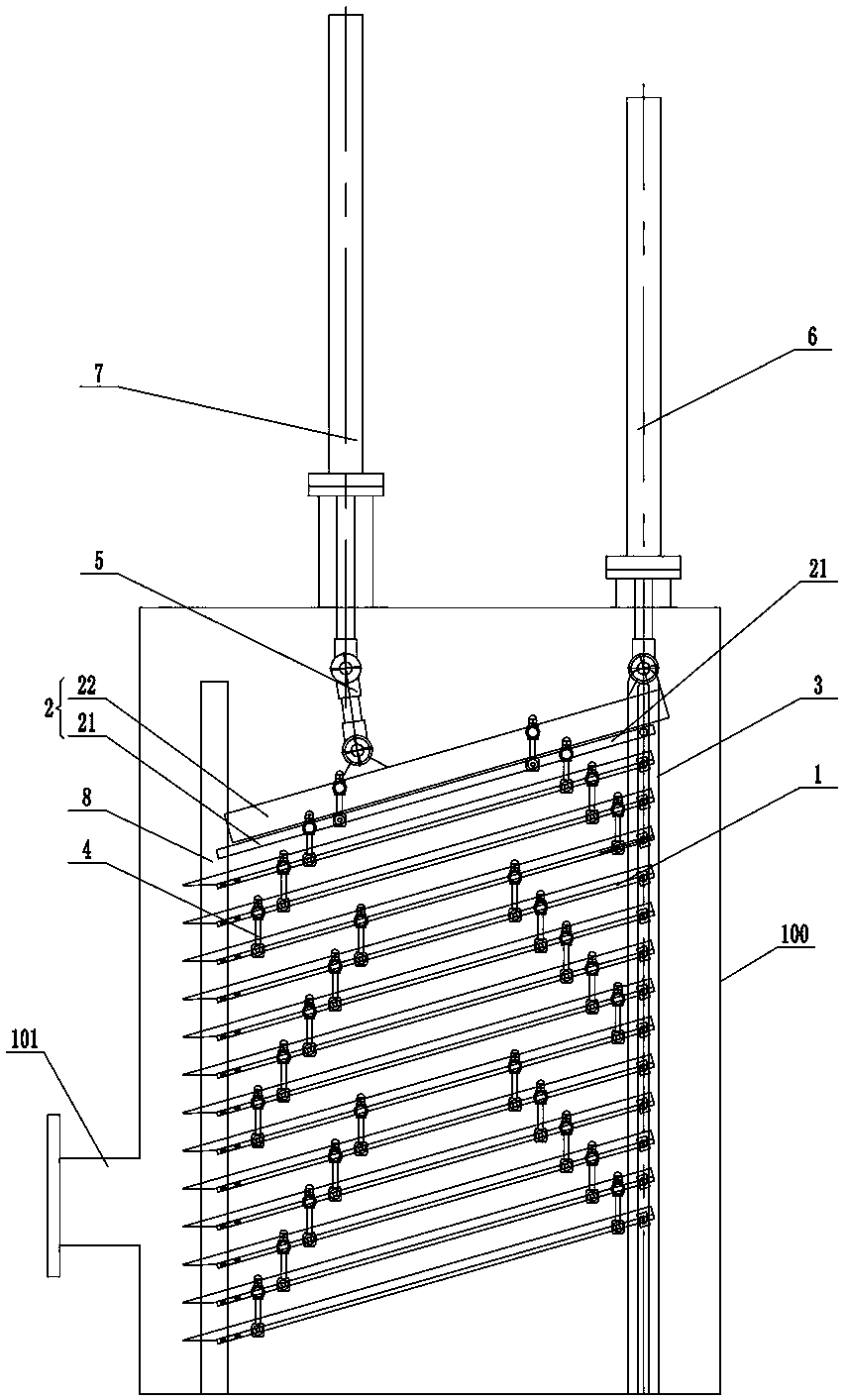

[0030] Figure 1 to Figure 6 It shows the embodiment of the first kind of lyophilizer with liftable and tiltable slabs of the present invention. The lyophilizer includes a slab group, and suspenders 4 are arranged between adjacent slabs of the slab group, and the slabs At least one side of the group is provided with a restraint 3 for restricting the movement of the slabs in the horizontal direction. Each slab can be rotatably connected to the restraint 3 and can be lifted along the restraint 3. The freeze dryer also includes a device for driving the slabs A group of rotating and lifting first driving parts 6 and second driving parts 7, and at least one of the first driving parts 6 and the second driving parts 7 is connected to the plate group through the interme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com