A freeze-drying machine with a plate layer that can be lifted and tilted

A freeze-drying machine and plate technology, applied in the field of freeze-drying machines, can solve the problems of limited inclination angle of freeze-dried plates, difficult pouring of residual moisture, complex transmission structure, etc. The effect of high water efficiency and simplified transmission structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

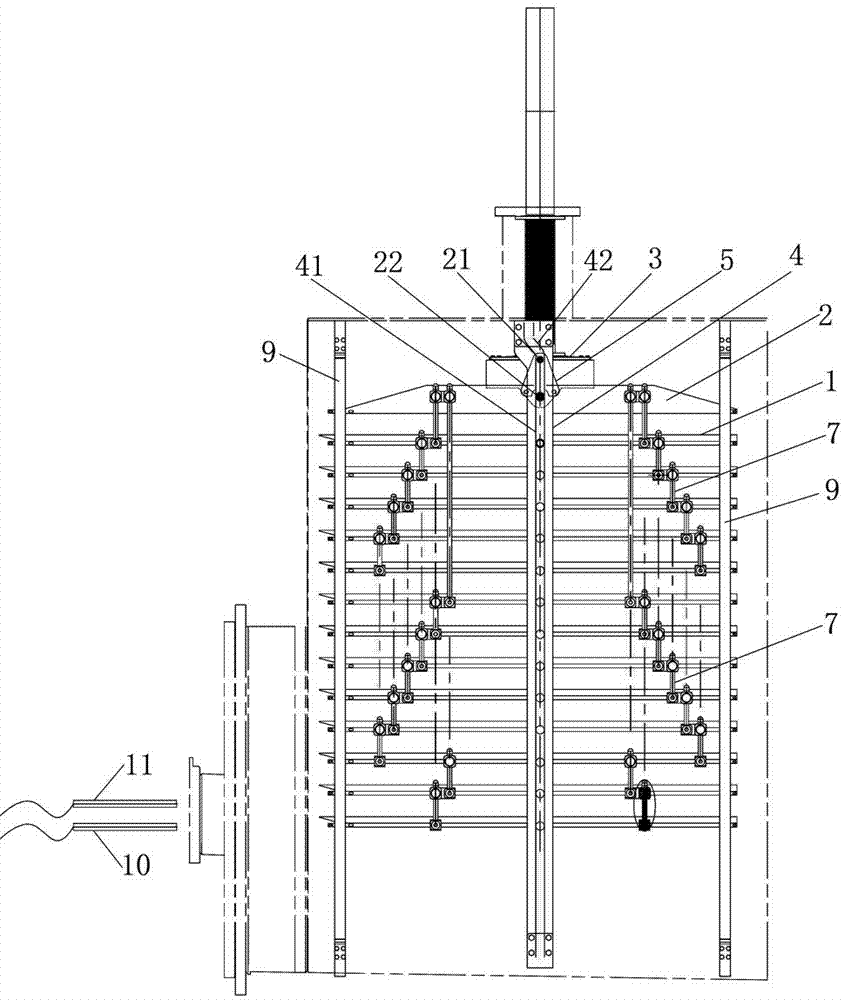

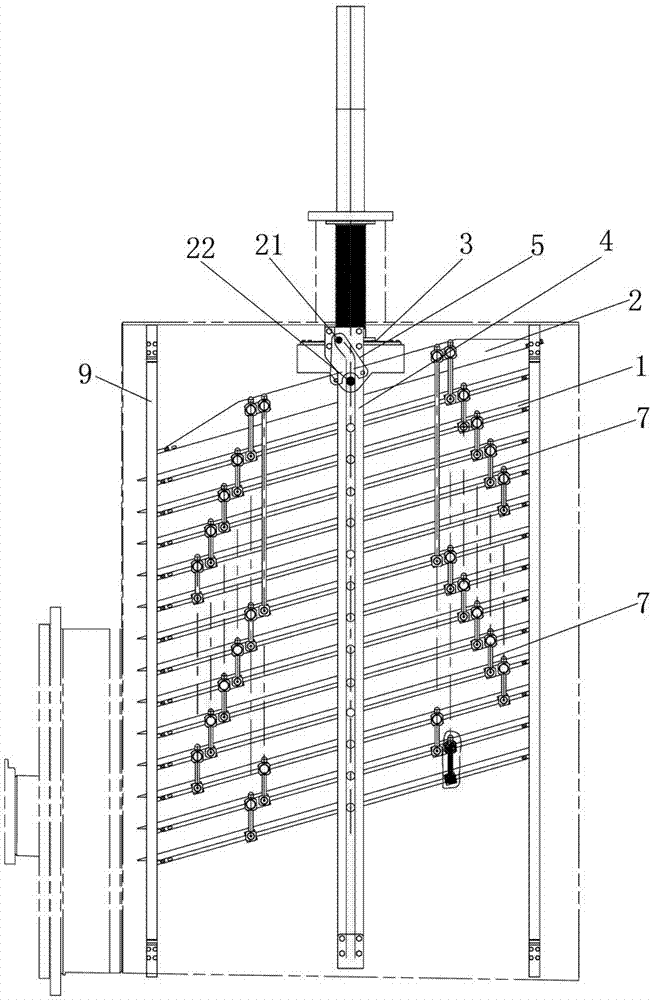

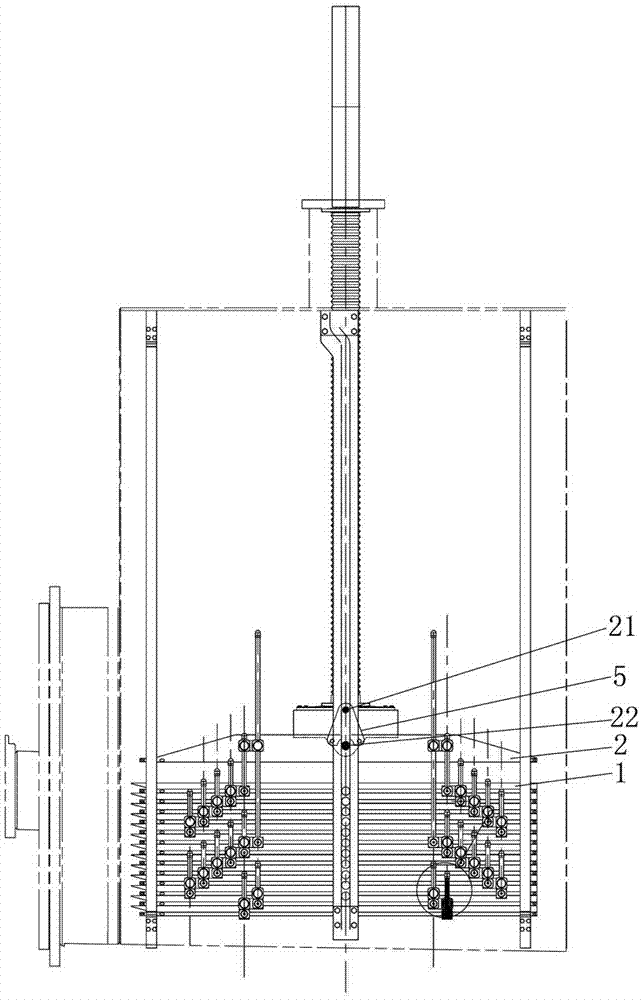

[0028] Such as Figure 1 to Figure 6 As shown, the lyophilizer with liftable and tiltable slabs in this embodiment includes a driving member 3, additional slabs 2 and several lyophilized slabs 1, and several lyophilized slabs 1 are connected below the additional slabs 2, and The movement of the additional plate 2 keeps synchronous linkage. The additional plate 2 is provided with a guide piece 21 and a connecting piece 22. The driving piece 3 and the additional plate 2 are hinged through the connecting piece 22 and drives the additional plate 2 up and down. The additional plate 2 At least one side of 2 is provided with a restraint 4, and the restraint 4 is provided with a vertical guide section 41 that guides the guide 21 and the connecting member 22 to make the additional board layer 2 rise and fall, and guides the guide 21 to make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com