A double-layer groove super wear-resistant high-speed washing machine bearing

A washing machine, ultra-wear-resistant technology, applied in the direction of ball bearings, shafts and bearings, bearing cooling, etc., can solve the problems of low service life of high-speed bearings, and achieve the effects of reducing friction points, high life, and low frictional heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

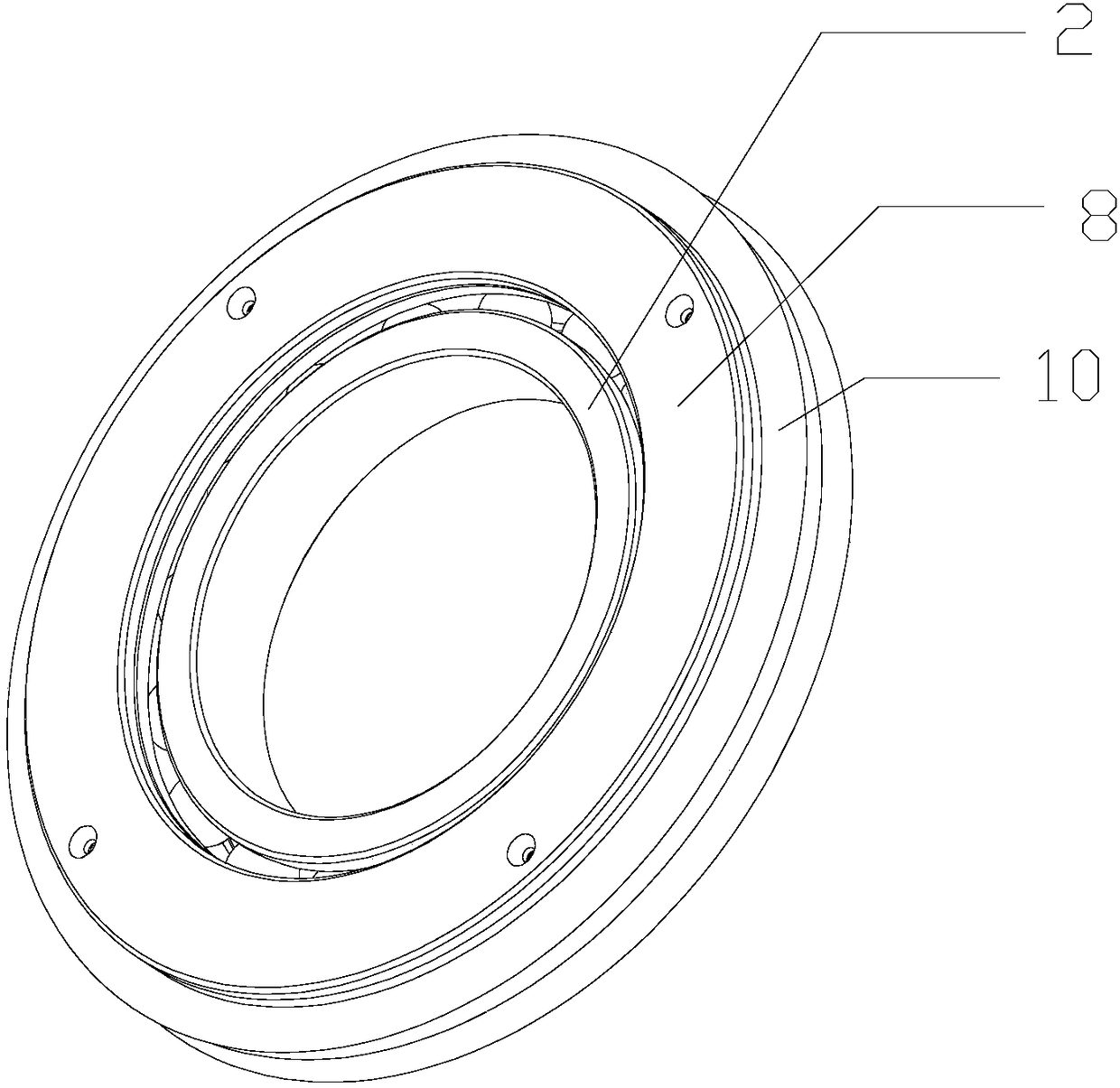

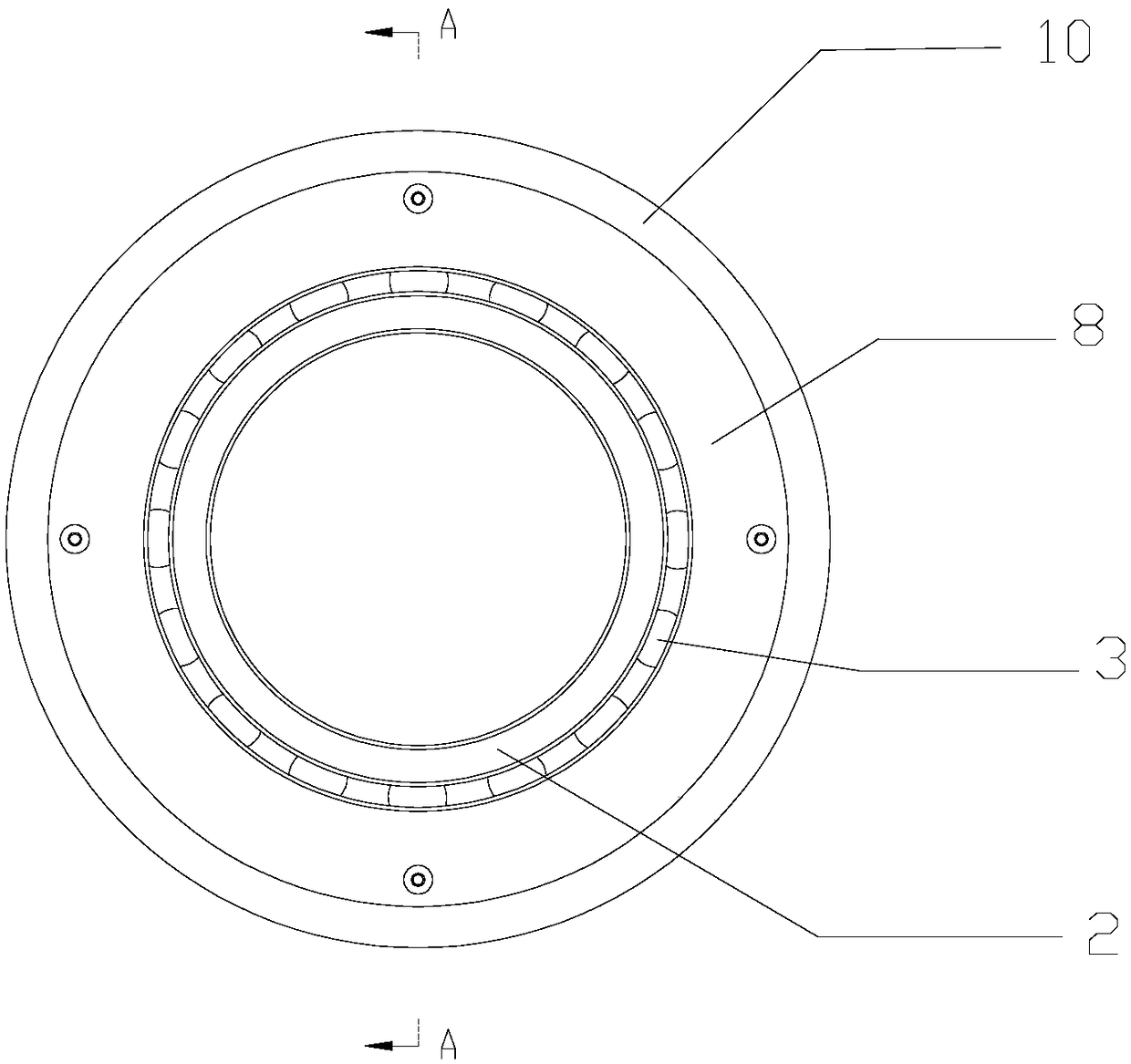

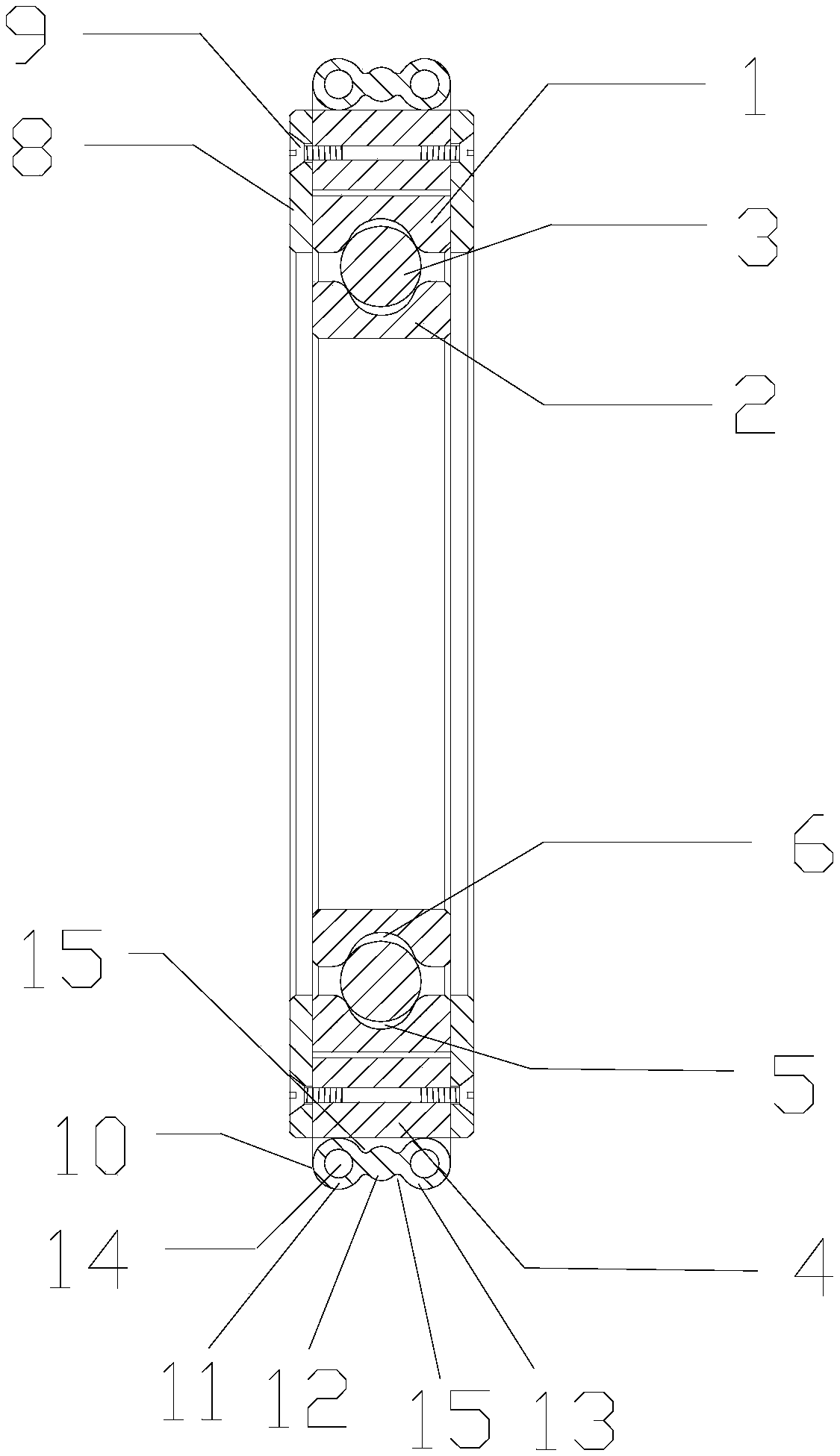

[0026] The structure of the double-layer ditch ultra-wear-resistant high-speed washing machine bearing in the embodiment of the present invention is as follows: Figure 1 to Figure 4 It includes: an outer ring 1 , an inner ring 2 , several rolling elements 3 and an adjustment ring 4 .

[0027] The inner peripheral surface of the outer ring 1 is provided with an outer groove 5, and the outer peripheral surface of the inner ring 2 is provided with an inner groove 6. Several rolling elements 3 are embedded between the outer groove 5 and the inner groove 6, and each Each rolling body 3 is in point contact with the outer groove 5 and the inner groove 6, that is, the contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com