Pressure-bearing underwater mining analog simulation testing device

A technology similar to simulation and test equipment, used in measuring equipment, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of synchronous sinking motion, test distortion, and inability to transmit downwards, and achieve the production process. Simple, high accuracy of pressure regulation, and the effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

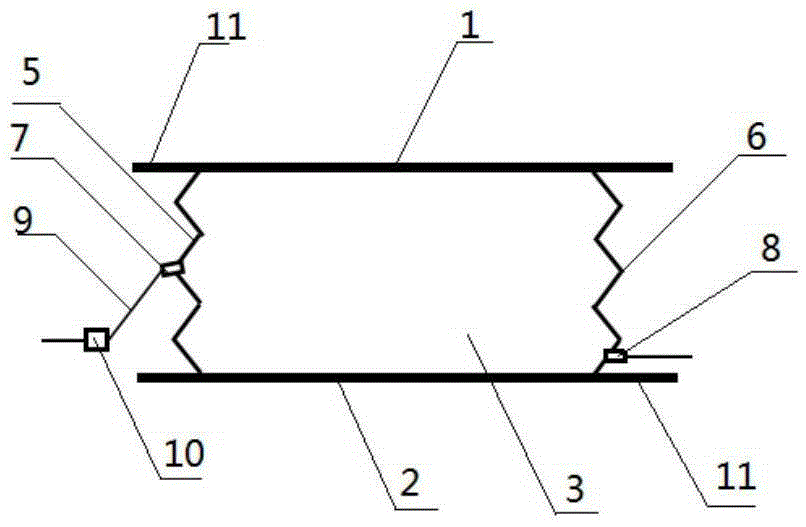

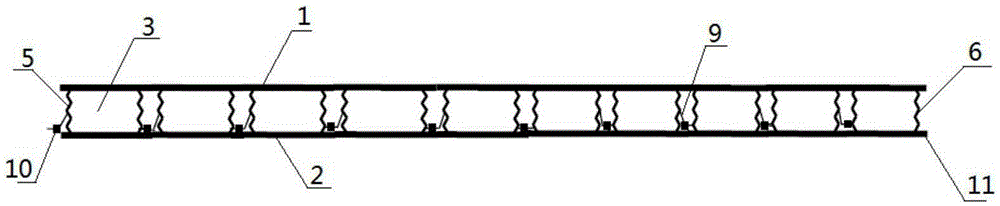

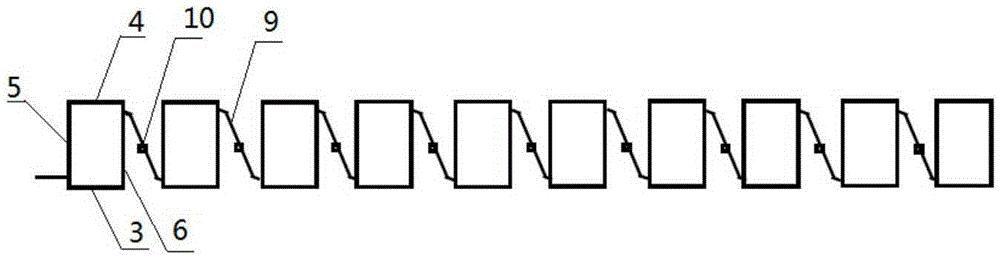

[0040] A similar simulated test device for confined underwater coal mining, including a support frame and a coal seam and a rock formation erected thereon, and a confined aquifer is arranged in the rock formation, such as Figure 1-Figure 4 As shown, the confined aquifer is formed by connecting a plurality of small water bags, and the small water bags are composed of a top plate 1, a bottom plate 2, a front side wall 3, a rear side wall 4, a left side wall 5 and a right side wall 6 enclosed cuboid structure, its inside is a water-filled space, a water inlet 7 is arranged on the left side wall of the small water bag, and a water outlet 8 is arranged on the right side wall, and the latter small water bag The water inlet 7 of the first described small water bag is connected with the water outlet 8 of the previous small water bag through the water delivery pipe 9, the water inlet 7 of the first described small water bag is connected with the water supply device, and the last descri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com