Elastic adhesive fatigue property test structure and manufacturing method thereof

A technology for fatigue performance testing and elastic adhesives, which is applied in the direction of measuring devices, instruments, and mechanical devices, can solve problems such as low work efficiency, affecting the accuracy of test results, and laborious problems, so as to reduce labor intensity and difficulty and shorten sample preparation. Time, the effect of improving sample preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

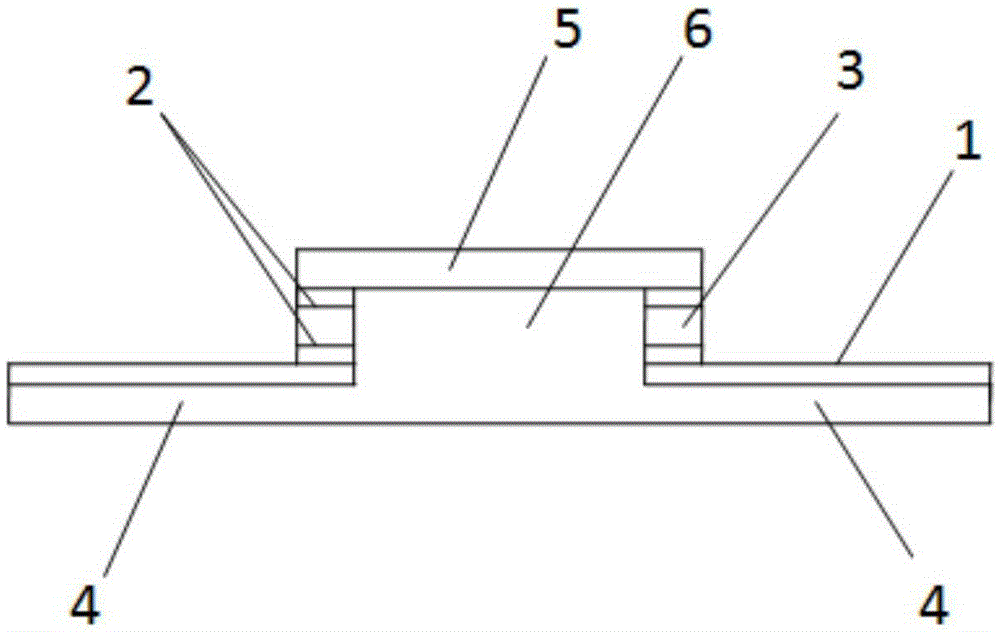

[0029] As a specific embodiment of the present invention, aluminum flakes and glass flakes are used as substrates. Aluminum flake 1 is a cuboid with a size of 100mm*25mm*2mm; glass flake 5 is a cuboid with a size of 100mm*25mm*5mm; aluminum flake, glass The sheet is cleaned with cleaning agent first, and after drying, the surface of the end of the aluminum sheet is treated with primer 2, and the treatment size is 100mm*25mm*12.5mm; the surface of both ends of the glass sheet is treated with primer 2, and the treatment size is 100mm* 25mm*12.5mm. The aluminum sheet 1 is placed on the first operation part of the sample preparation operation platform, and the end treated by the primer 2 is placed close to the second operation part upwards, and a 4 mm thick one-component moisture-curing polyurethane elastic adhesive 3 is coated on it, and the The glass piece 5 is placed on the second operating part of the sample preparation operation platform, and the surface treated by the primer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com