Work state early-warning method and system for high-voltage insulator of electrical railway

A high-voltage insulator, working state technology, applied in the field of electric power, can solve the problem of insulator leakage current and fail to warn the safety of high-voltage insulator running state, and achieve the effect of being accurate and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

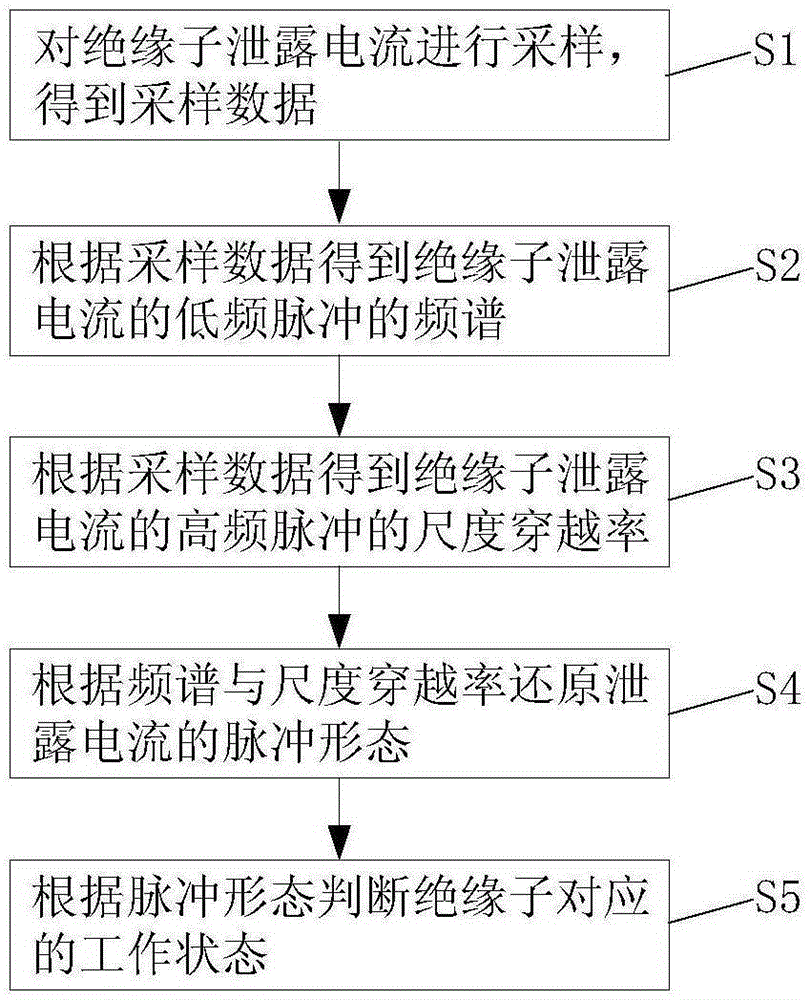

[0051] Such as figure 1 As shown, this embodiment provides a method for early warning of the working state of an electric railway high-voltage insulator, including the following steps:

[0052] S1: Sampling the leakage current of the insulator to obtain the sampling data of the leakage current of the insulator. For example, it can be sampled through the current acquisition loop, and the sampling can take half a cycle of the power frequency (10ms) as a working cycle, and the power frequency waveform can be locked by the phase-locked loop. Before step S1, it may also include collecting the maximum magnitude of the insulator leakage current and judging whether the maximum magnitude exceeds the preset threshold, and if so, proceed to steps S2 and S3, which are equalized by voltage comparators in the prior art. It can be realized, and will not be described in detail here; since the working state of the insulator may start to deteriorate only when the maximum magnitude of the leaka...

Embodiment 2

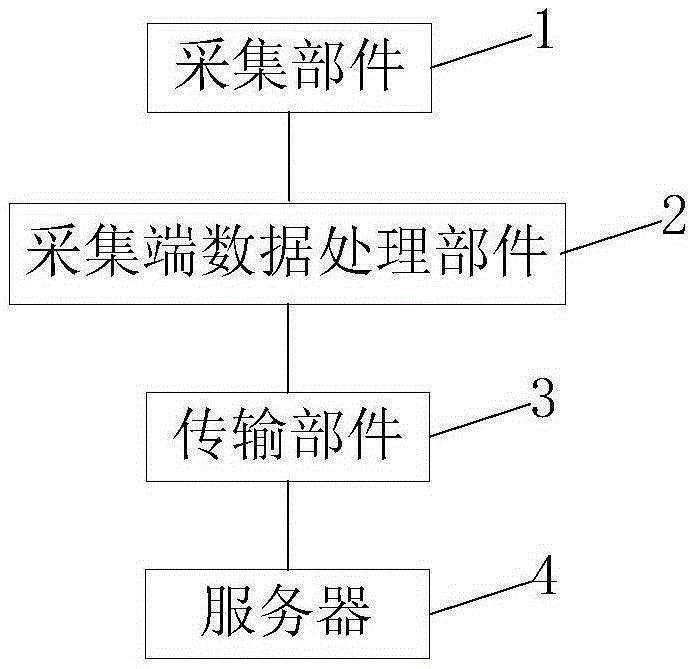

[0066] Such as figure 2 As shown, the present embodiment provides a working state early warning system for electric railway high-voltage insulators, including:

[0067] The collecting part 1 is connected with the insulator and is used for sampling the leakage current of the insulator to obtain the sampling data of the leakage current of the insulator. Specifically, the collection unit 1 can be hung on the leakage line of each string of insulators. Most of the collection components in the prior art realize the sampling of insulator leakage current by passing through the leakage line, but in real life, many insulators are close to the utility poles, at this time the collection components in the prior art will not be able to pass through The purpose of sampling the leakage current of the insulator is achieved by using the leakage line. The collection part mentioned in this embodiment can be designed in a ring shape, which is set on the utility pole to achieve the purpose of sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com