Assembling apparatus and assembling method suitable for assembling square lithium battery pole group

A technology for assembling device and lithium battery, applied in the field of lithium ion battery, can solve problems such as winding core vibration, and achieve the effect of preventing safety failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below.

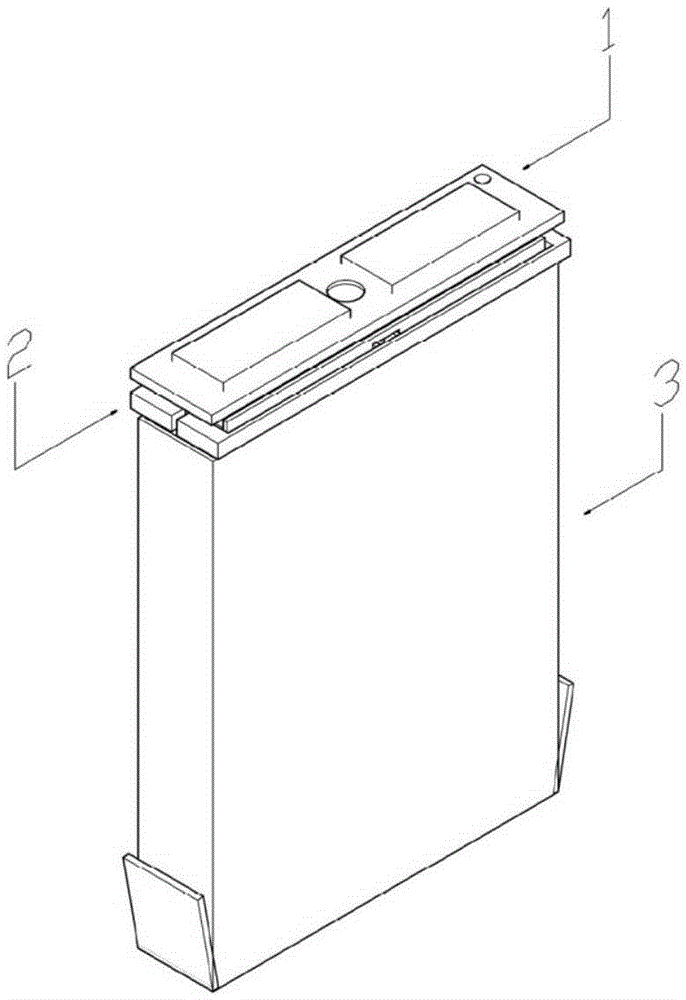

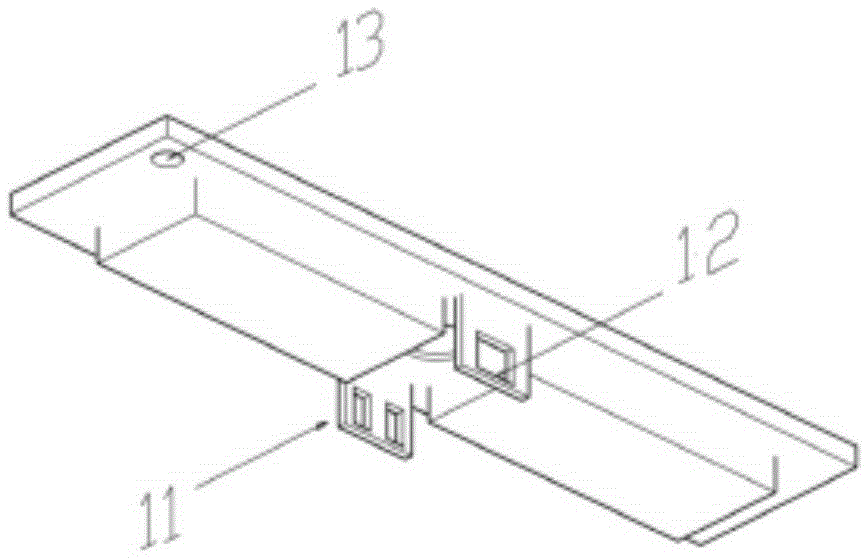

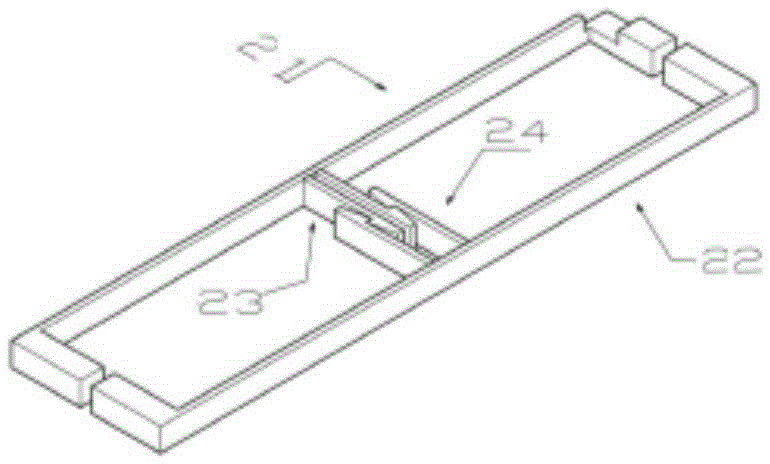

[0025] Such as Figure 1 ~ Figure 4 As shown, the present invention discloses an assembly method and assembly device suitable for assembling a square lithium battery pole group, including a cover plate 1 , an insulating stop frame 2 , and a protective film 3 . During the assembly process of the battery cell, firstly, the pole group is welded to the cover plate 3, and the positive and negative tabs of the pole group are welded to the positive and negative connecting pieces of the cover plate 3 to ensure that there is no false welding or over-welding at the welding point.

[0026] The welded electrode group and the electrode group part of the cover plate are placed in the protective film 3 , and the protective film 3 can completely cover the electrode group part after being folded according to the corresponding creases. After wrapping, ensure that the first hole 31 and the second hole 32 on the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com