Method for measuring sealing performance of seal of cylindrical lithium ion battery

A lithium-ion battery, cylindrical technology, applied in the field of battery sealing measurement, can solve the problems of inaccurate measurement, water splash, easy to hurt people, etc., and achieve the effect of avoiding safety failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

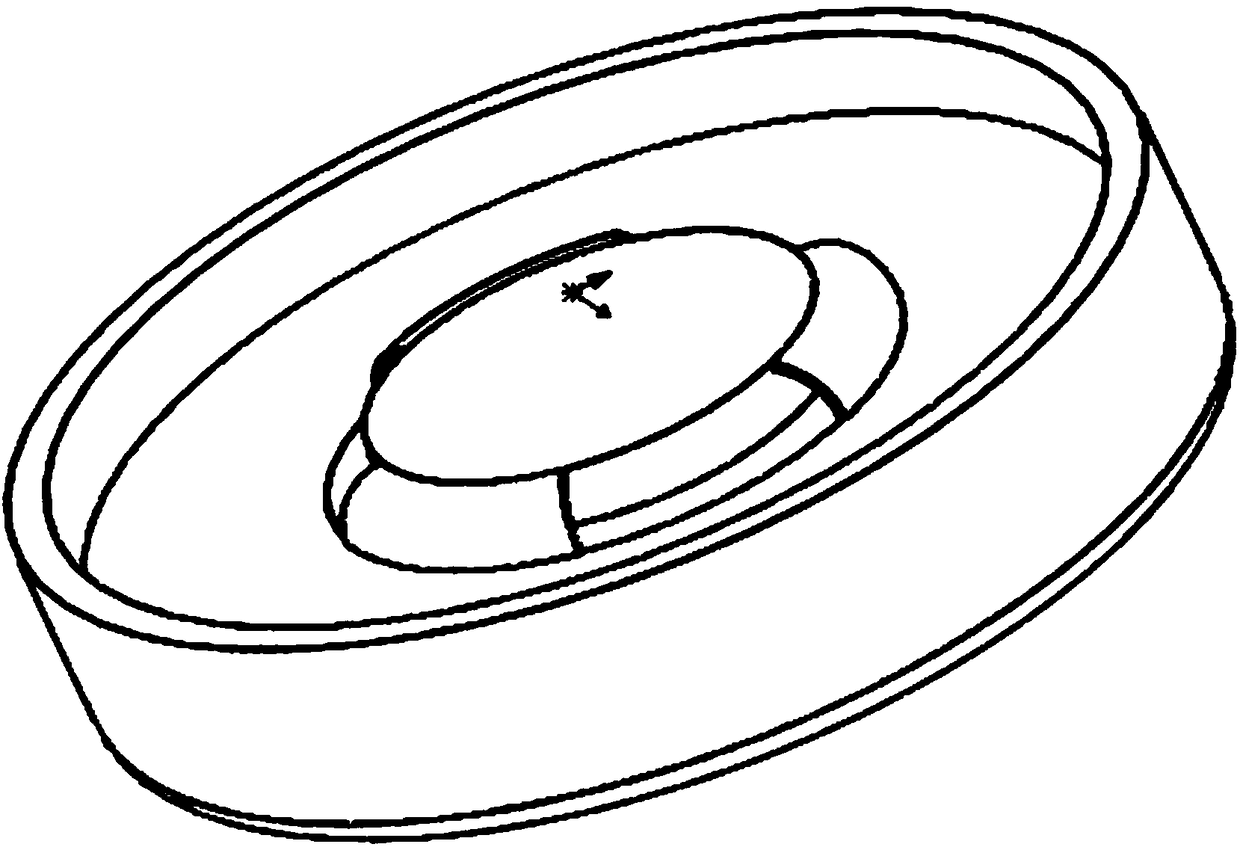

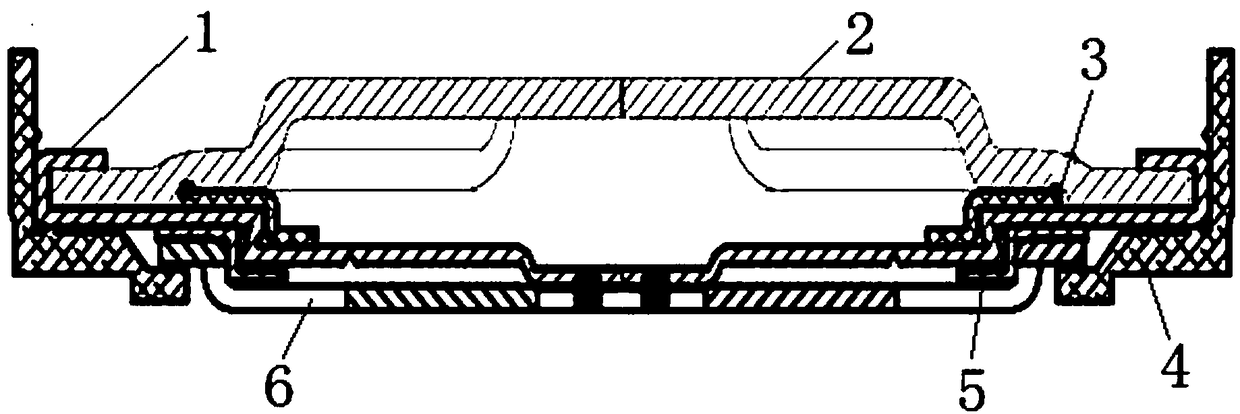

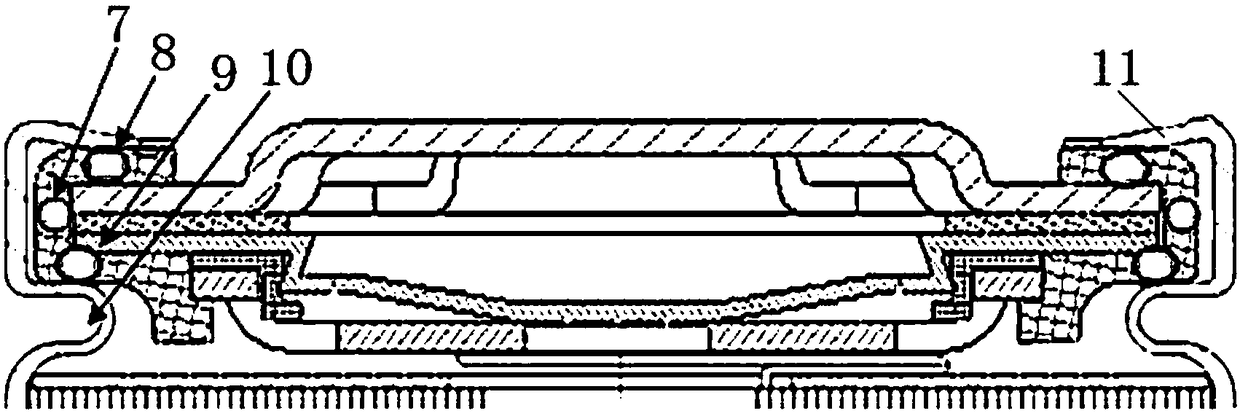

[0028] Such as Figure 1-3 As shown, the invention discloses a method for measuring the sealing performance of a cylindrical lithium-ion battery, comprising the steps of:

[0029] Step S01: measuring the thickness of the same batch of aprons 4;

[0030] Step S02: sealing the cell of the cylindrical lithium-ion battery with the cap welded;

[0031] Step S03: cutting the sealed cap from the roller notch 10;

[0032] Step S04: Cut the cap from the middle;

[0033] Step S05: smoothing the profile of the cap;

[0034] Step S06: use a two-dimensional projector to project the profile of the cap, and measure the thickness of the rubber ring 4 under projection;

[0035] Step S07: Calculate the compression ratio of the apron 4 .

[0036] In step S06, it is necessary to measure the thickness of the apron at the extrusion part where the cap and the steel shell 11 are in close contact, and measure under the projection image 3 The thickness of the apron 4 at the three positions of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com