Sound tube

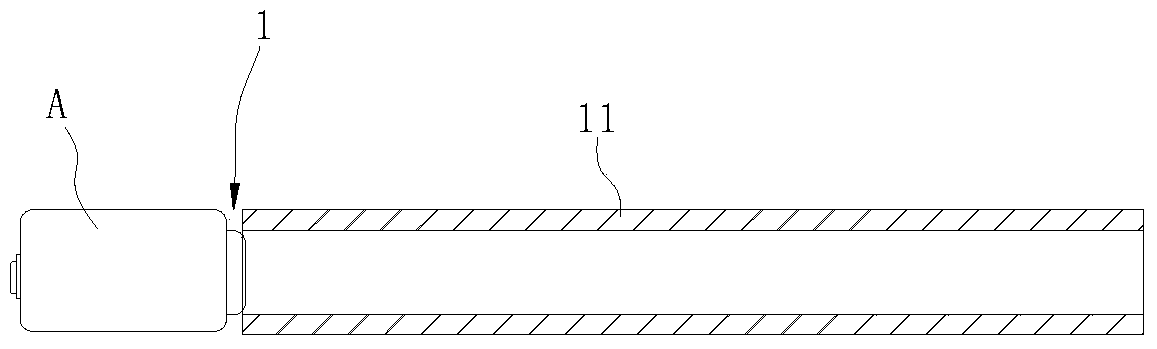

A technology of a sound guide tube and a tube body, which is applied in the field of sound guide tubes, can solve the problems of inability to improve the structure of the sound guide tube, staying in the sound guide tube, and inability to further improve the influence of the sound guide tube on the sound quality of headphones.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

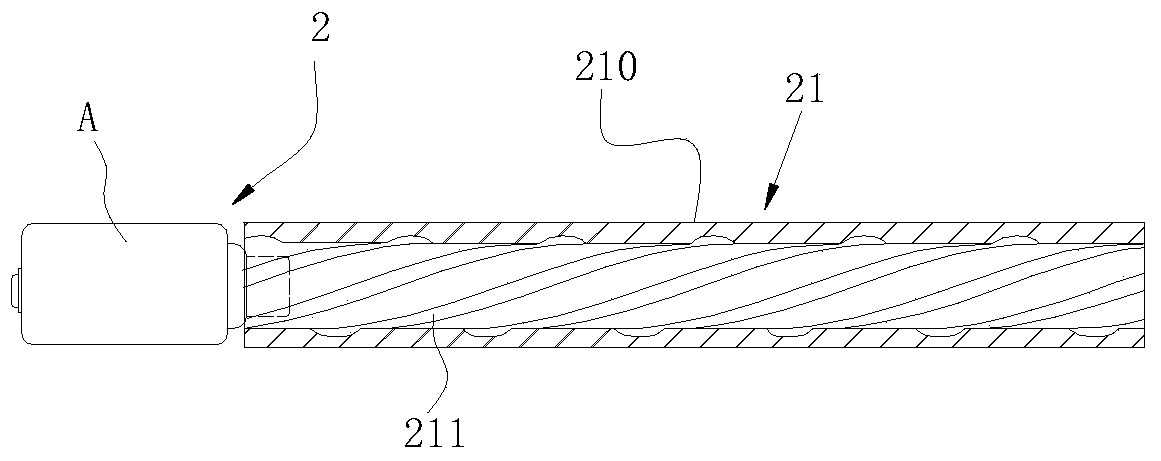

Embodiment 1

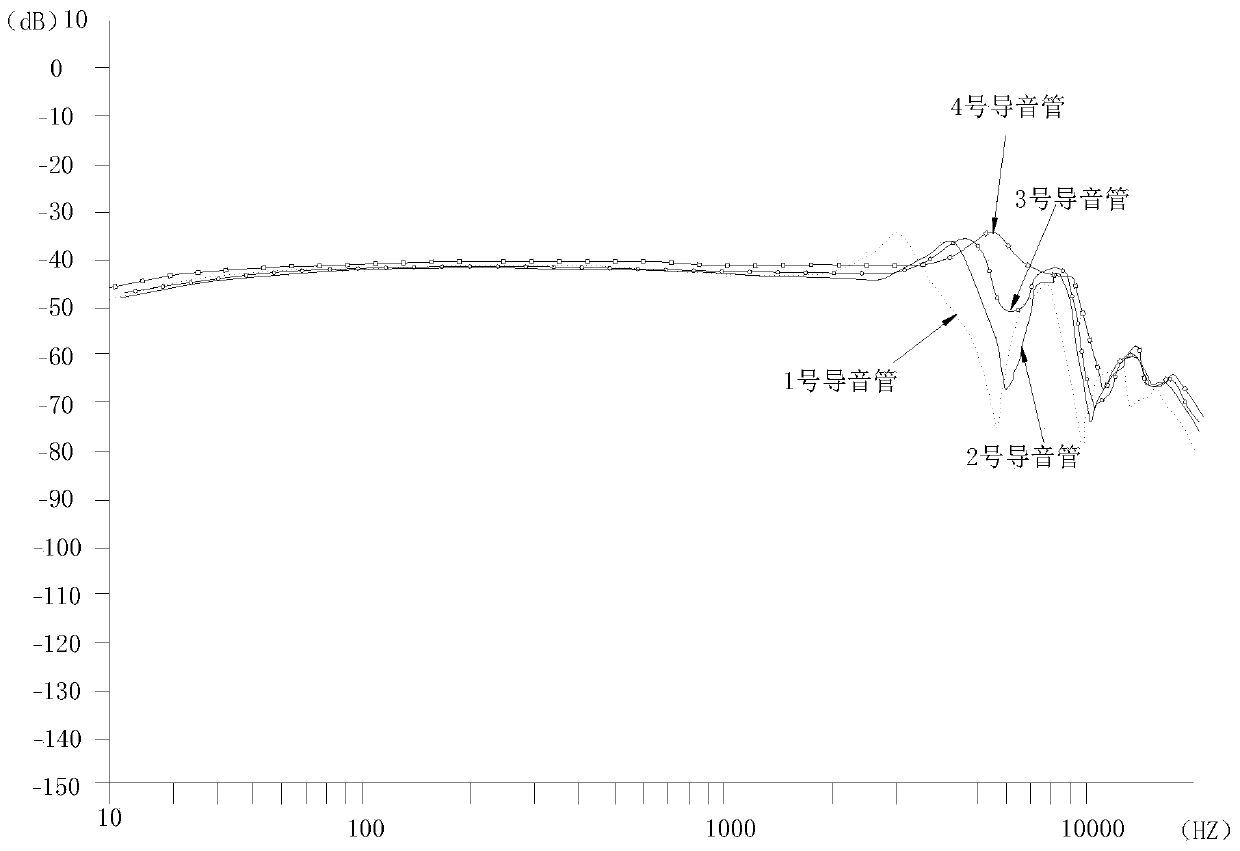

[0020] The test object of this embodiment includes No. 1 sound guide tube which is the sound guide tube in the prior art, No. 2 sound guide tube with a helical groove helix angle of 45°, and No. 3 sound guide tube with a helical groove helix angle of 60° Sound guide tube, No. 4 sound guide tube with helical groove with a helix angle of 75°. The length of the above four test objects is 4cm, the diameter of the inner hole is 2mm, and the wall thickness is 1mm, and they are all made of silica gel material. 000. The number of spiral grooves in the sound guide tubes with spiral grooves on the inner wall is 6, and the depth of the spiral grooves is 0.15mm.

[0021] When testing, connect one end of the above-mentioned four sound guide tubes to the sound outlet of the moving iron unit respectively, and the connection between the two is strictly sealed, and then connect the moving iron unit to the electroacoustic tester through a wire, and the electroacoustic The signal generator ins...

Embodiment 2

[0027]The test object of this embodiment includes No. 1 sound guide tube which is the sound guide tube in the prior art, No. 5 sound guide tube with 4 spiral grooves, and No. 6 sound guide with 5 spiral grooves. Tube, No. 7 sound guide tube with 7 helical grooves. The length of the above four test objects is 4cm, the diameter of the inner hole is 2mm, and the wall thickness is 1mm, and they are all made of EVA material. 000. The helix angle of the helical grooves in the sound guide tube with the helical grooves on the inner wall is 60°, and the depth of the helical grooves is 0.15mm.

[0028] When testing, connect one end of the above-mentioned four sound guide tubes to the sound outlet of the moving iron unit respectively, and the connection between the two is strictly sealed, and then connect the moving iron unit to the electroacoustic tester through a wire, and the electroacoustic The signal generator inside the tester outputs a stable voltage of 152mV and sweep frequency...

Embodiment 3

[0034] The test object of this embodiment includes No. 1 sound guide tube which is the sound guide tube in the prior art, No. 8 sound guide tube with a spiral groove depth of 0.1 mm, and No. 9 sound guide tube with a spiral groove depth of 0.2 mm. Tube, a No. 10 sound guide tube with a helical groove depth of 0.3mm. The length of the above four test objects is 4cm, the diameter of the inner hole is 2mm, and the wall thickness is 1mm, and they are all made of EVA material. 000. The helix angles of the helical grooves in the sound guide tubes with the helical grooves on the inner wall are all 60°, and the number of the helical grooves is 6.

[0035] When testing, connect one end of the above-mentioned four sound guide tubes to the sound outlet of the moving iron unit respectively, and the connection between the two is strictly sealed, and then connect the moving iron unit to the electroacoustic tester through a wire, and the electroacoustic The signal generator inside the test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com