Method for operating an electrically operated friction brake

A technology of friction brakes and electric operation, applied in the direction of brakes, mechanical brakes, brake transmissions, etc., can solve problems such as inaccuracy, wheel locking, and inappropriateness, and achieve the effect of avoiding inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

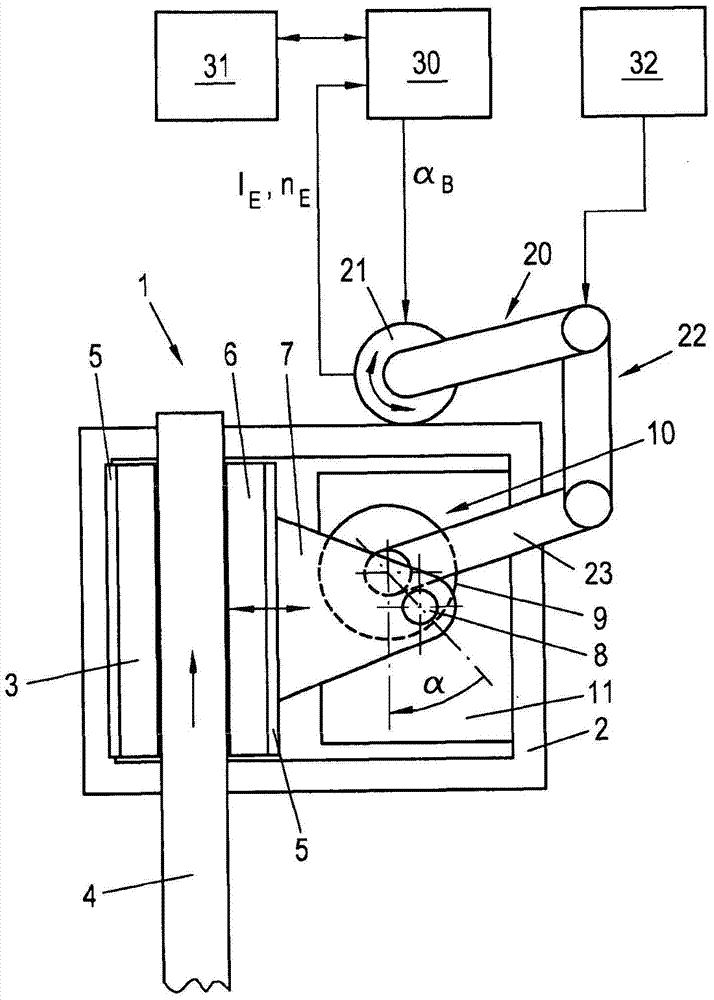

[0024] Refer below figure 1 By way of example, the invention is explained in detail with the aid of a schematically shown electrically operated friction brake 1 in the form of a floating caliper disc brake. Floating-caliper disc brakes, as often installed in vehicles, are sufficiently known per se, so that the features and function of floating-caliper disc brakes and the basic installation of floating-caliper disc brakes, such as in vehicles, will not be described in detail here. In principle, however, the invention can also be used for other types of brakes, such as drum brakes. It is also possible to provide a further friction surface as a brake disc or drum, such as a more or less flat surface, for example as a brake for a linear movement.

[0025] figure 1 A friction brake 1 is shown with a floating caliper 2 as a brake caliper, which surrounds a friction surface, here in the form of a brake disc 4 . A fixed brake lining 3 (relative to the floating caliper 2 ) and a mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com