cultivation device

A cultivation device and technology for cultivating plants are applied in the directions of cultivation, soilless cultivation, botanical equipment and methods, etc., which can solve the problems such as the efficiency of the cultivation area that is not realized, and achieve the effect of realizing the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

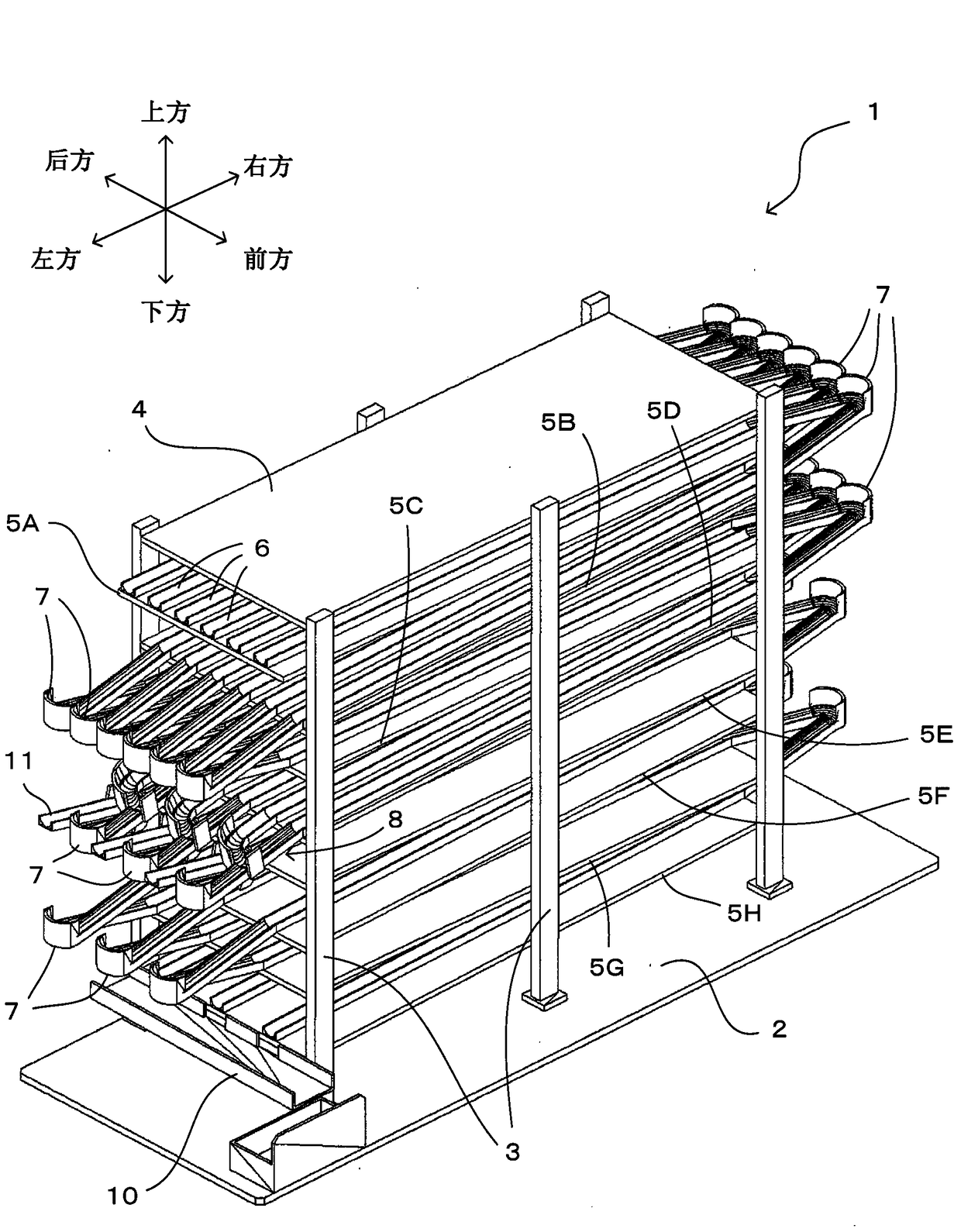

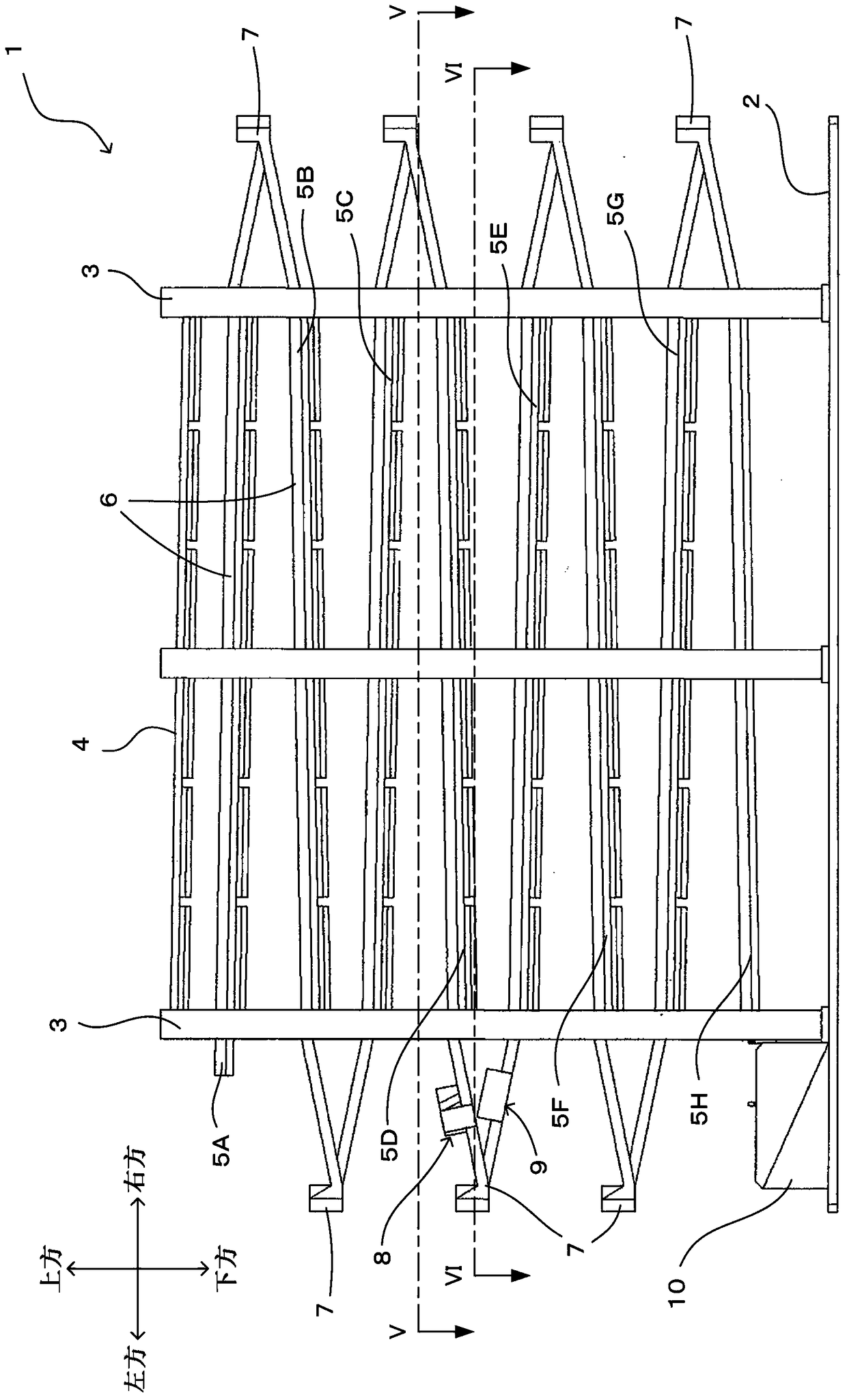

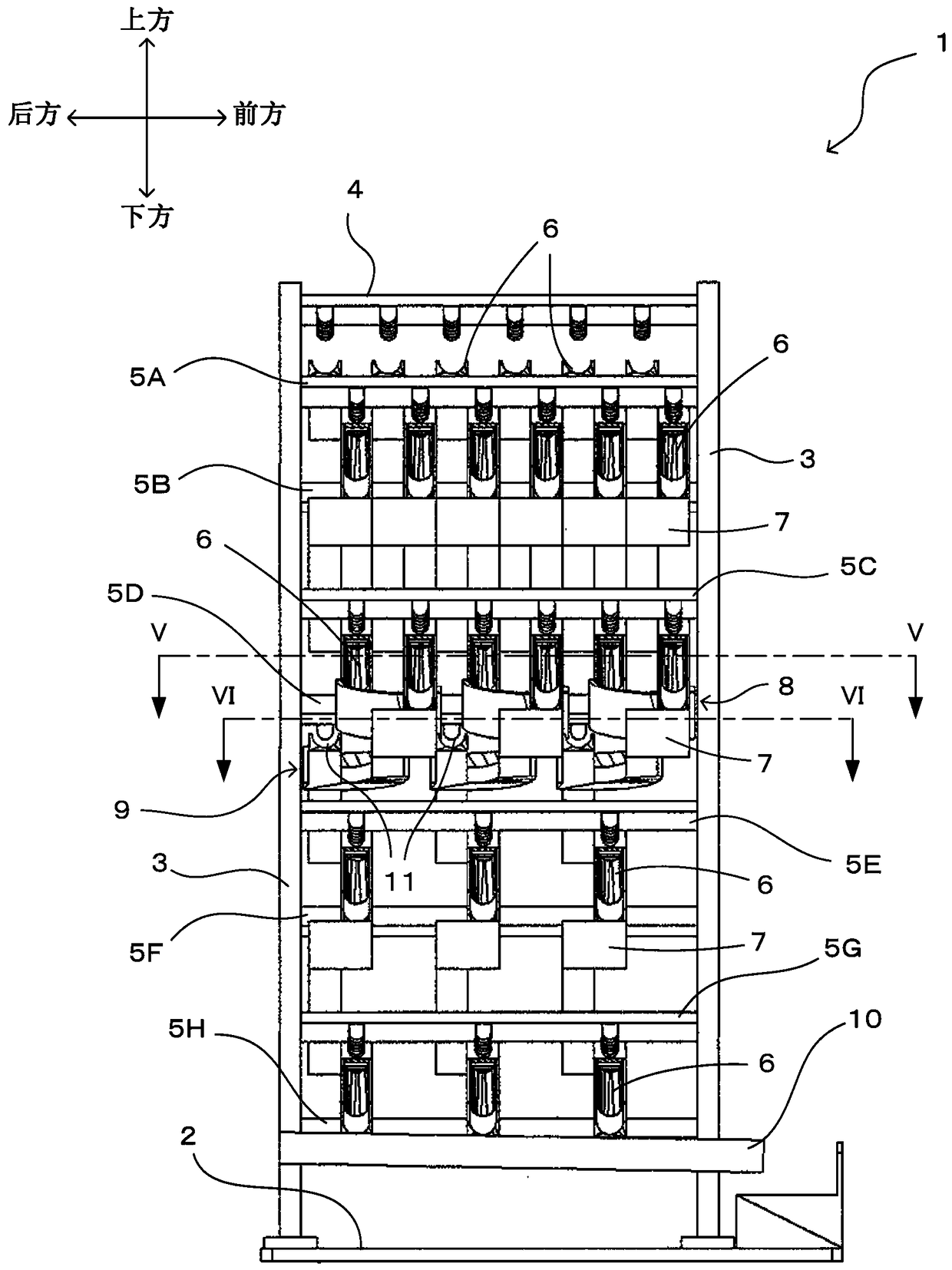

[0031] Hereinafter, one embodiment will be described with reference to the drawings. In addition, the directions of "front", "rear", "left", "right", "upper", and "lower" marked in each figure correspond to the directions described as "front (front)" in the description of the specification, respectively. ", "Back (Rear)", "Left (Left)", "Right (Right)", "Above (Up)", "Down (Down)" directions. In addition, in the following, directions such as up, down, left, and right are used as appropriate for the convenience of describing the structure of the cultivating device, but this is not intended to limit the positional relationship of the respective structures of the cultivating device.

[0032]

[0033] figure 1 Three-dimensionally express the overall appearance of the cultivating device of this embodiment, figure 2 The overall appearance of the cultivation device is expressed from the front viewed from the front, image 3 The overall appearance of the cultivation device is ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com