Assemble the inner magnet fixture of the keyboard aluminum rod

A technology for assembling jigs and inner magnets. It is used in manufacturing tools, metal processing, and metal processing equipment. It can solve problems such as high appearance defects, high overall misalignment, and defective scrap, and achieves a reduced misalignment rate and appearance. The effect of reducing the defective rate and the low defective scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

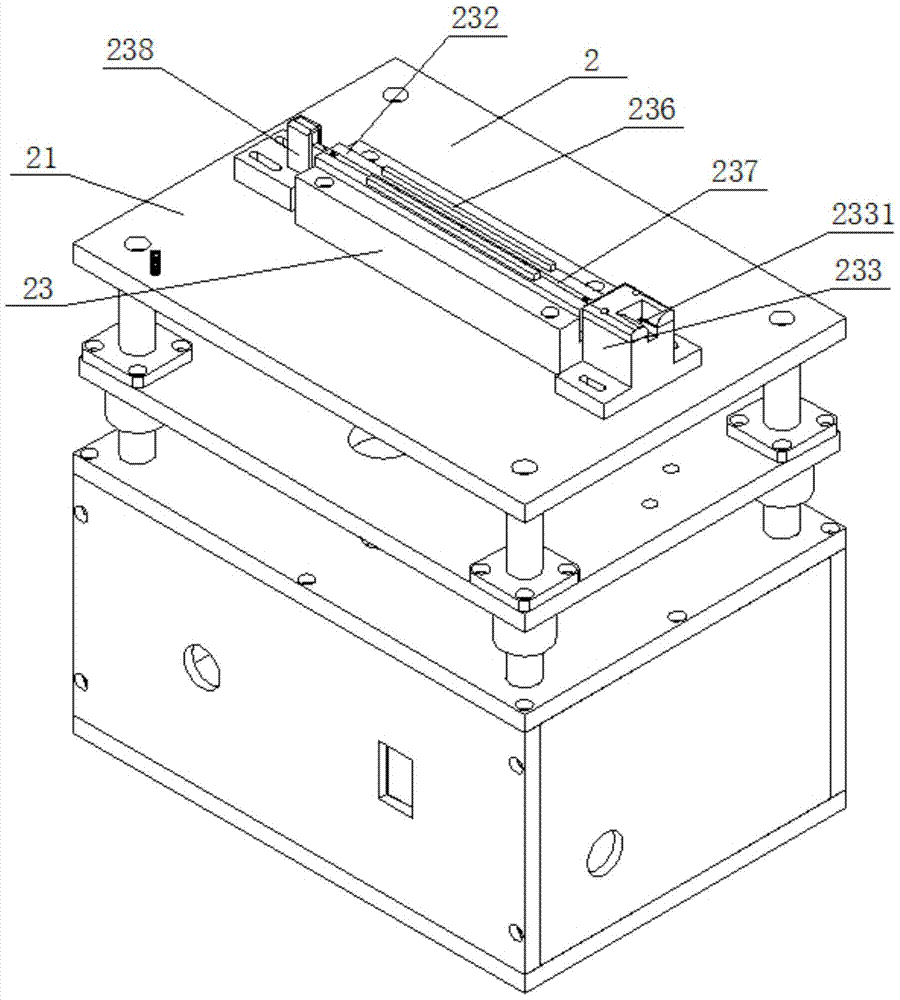

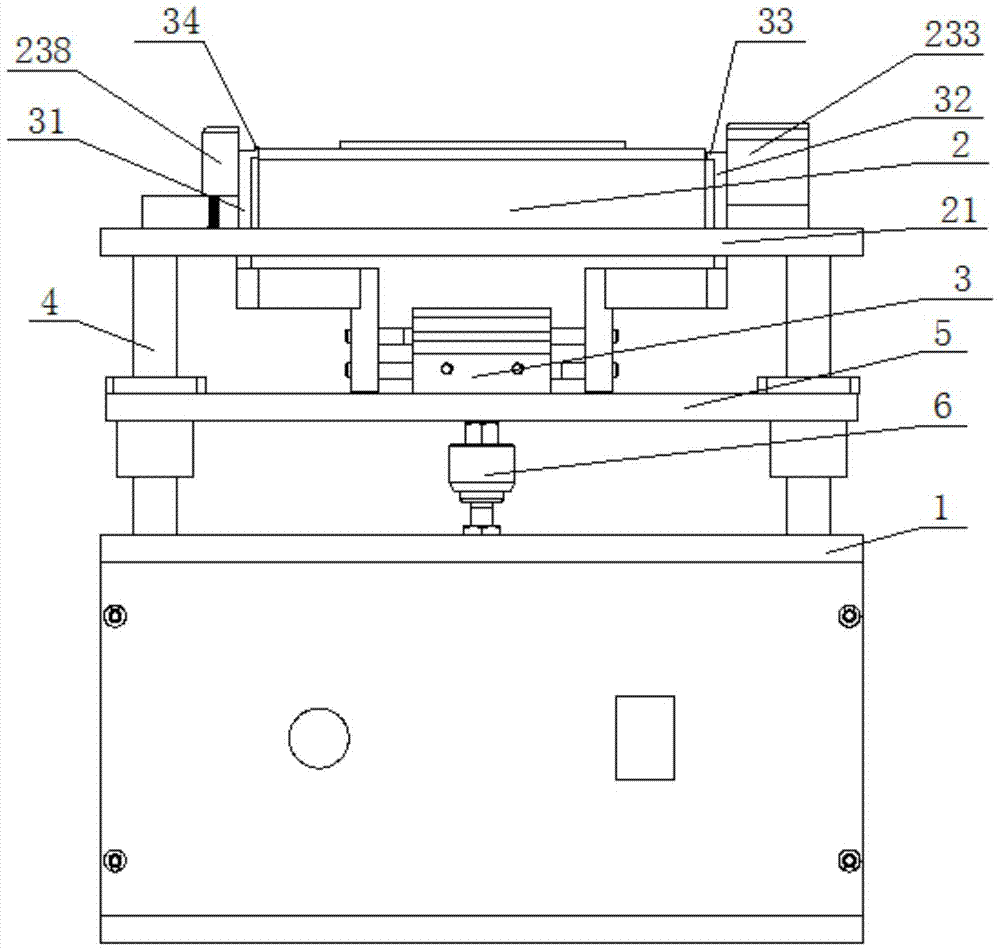

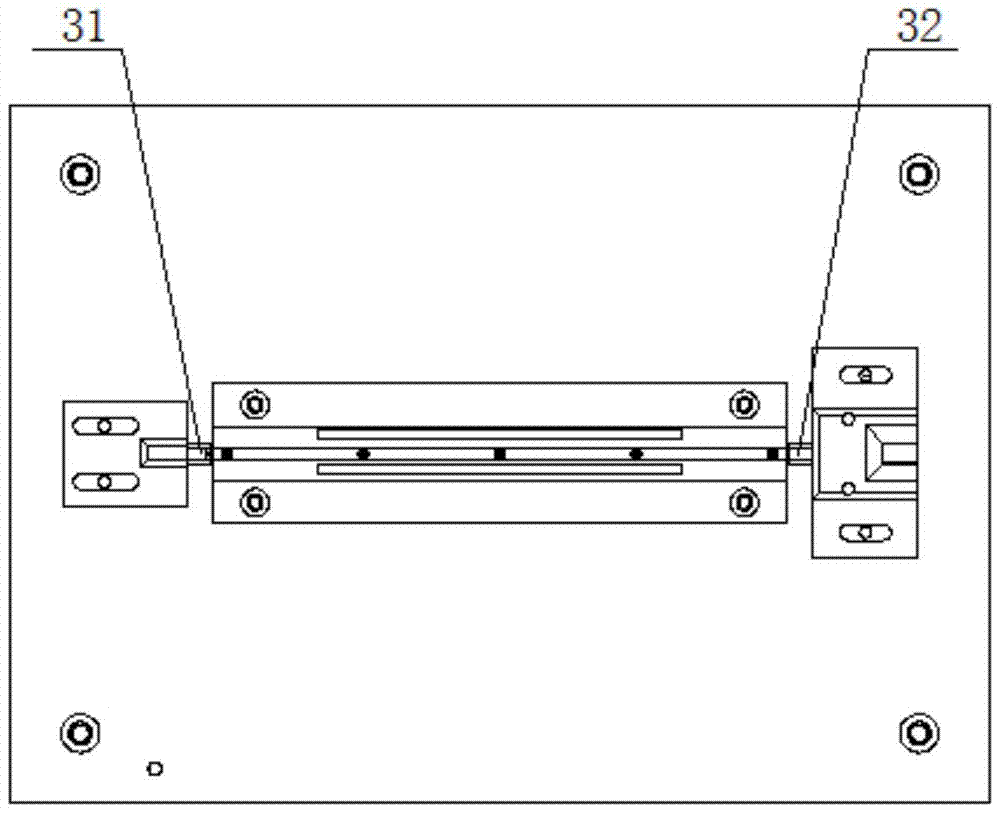

[0023] Such as Figure 1~4 The shown assembly keyboard aluminum bar inner magnet jig includes a machine platform 1, a magnet assembly jig 2 and parallel air claws 3, the magnet assembly jig 2 is arranged above the machine table 1, and the parallel air claws 3 It is arranged above the machine table 1 and below the magnet assembly jig 2 through a lifting mechanism.

[0024] The magnet assembly jig 2 includes a base 21 and a magnet positioning mechanism 23, the base 21 is supported on the top of the machine table 1 by at least two guide rods 4 and parallel to the table top, and the guide rods 4 are symmetrically arranged on the machine table 1 on both sides of the table top, the guide rod 4 is slidingly sleeved with a push plate 5, the push plate 5 is located between the table top of the machine table 1 and the base 21, the parallel air claw 3 is installed on the push plate 5, the machine A cylinder 6 for driving the push plate 5 to move up and down is installed on the platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com