Rear suspension of engine and four-point engine suspension system

An engine and rear suspension technology, applied in the direction of power plant, jet propulsion device, internal combustion propulsion device, etc., can solve problems such as assembly difficulty and affect assembly efficiency, and achieve reduced assembly difficulty, improved force bearing capacity, and good vibration damping performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

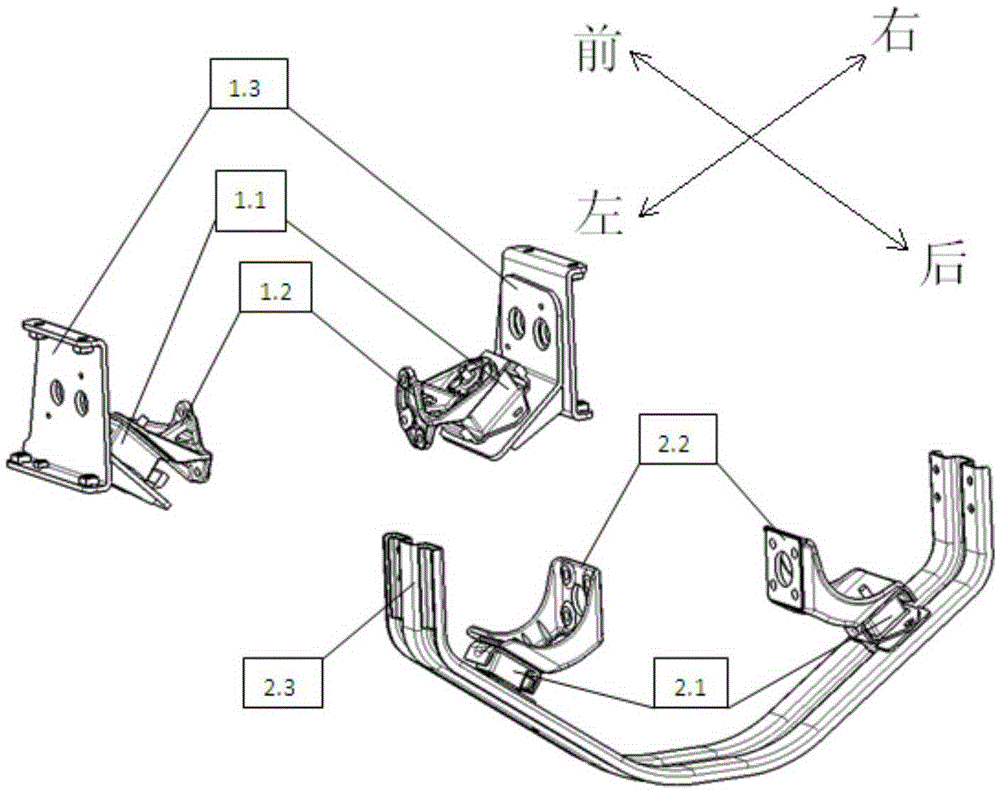

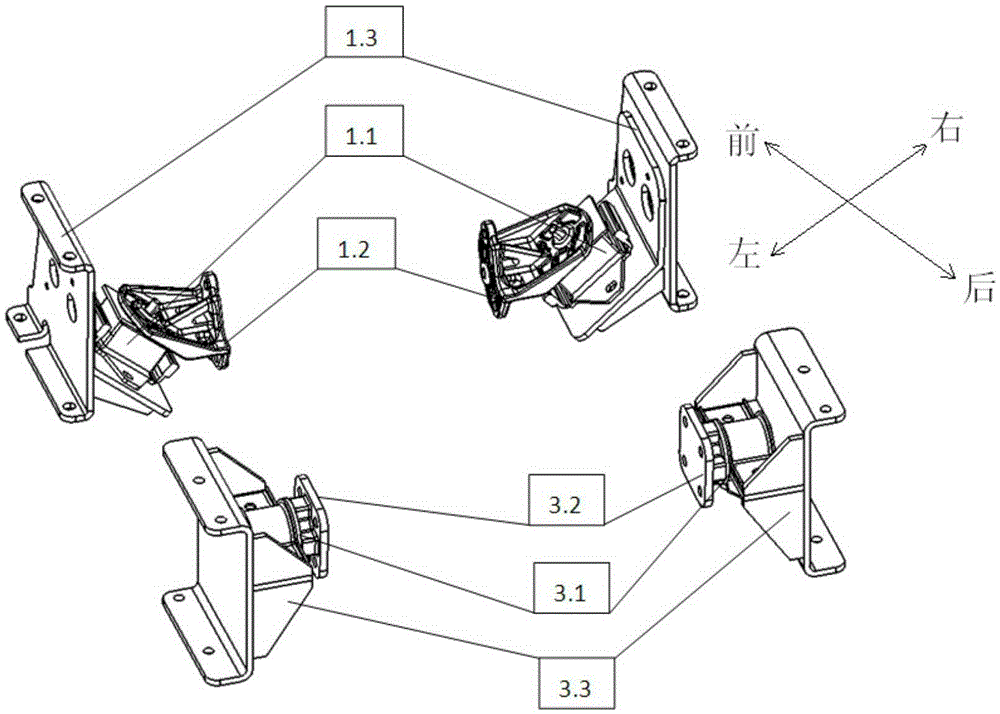

[0030] refer to figure 2 , the four-point engine mount system in this embodiment includes a pair of engine front mounts and a pair of engine rear mounts. Wherein, the front suspension of the engine is the same as the prior art, including a front suspension cushion 1.1, a front suspension bracket 1.3 and an engine bracket 1.2 connected together through the front suspension cushion 1.1. The improvement lies in the rear suspension of the engine, including: a rear suspension cushion 3.1, an engine foot 3.2 and a rear suspension bracket 3.3.

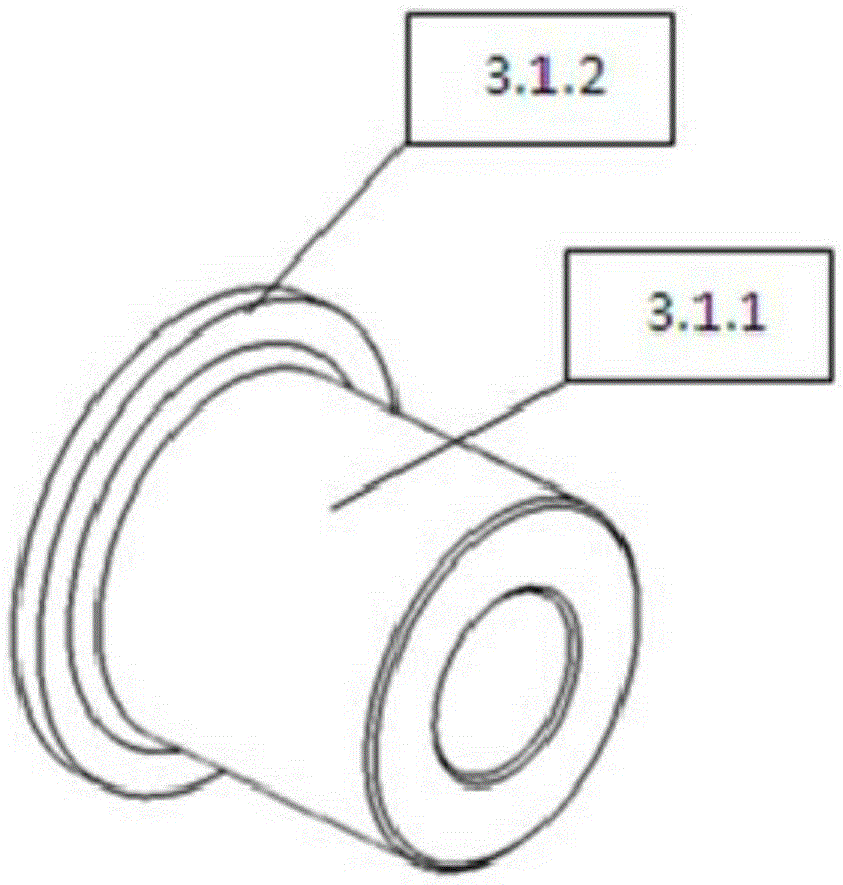

[0031] refer to figure 2 , the rear suspension cushion 3.1 is a rubber part, which has a tubular main part 3.1.1 and a limiting flange 3.1.2 located on the outer circumference of one end of the main part 3.1.1, that is, the main part 3.1.1 The central hole runs through the limit flange 3.1.2. By changing the radius and length of the main part 3.1.1 or changing the formula of the rubber material, the stiffness parameters of the rear suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com