A leading edge structure of an aircraft external auxiliary fuel tank that resists bird strikes

A technology for auxiliary fuel tanks and aircraft, applied to the fuel tanks of power plants, etc., can solve the problems of high manufacturing process requirements, increased difficulty, and increased test items, and achieve the effect of simple structural design and convenient manufacturing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

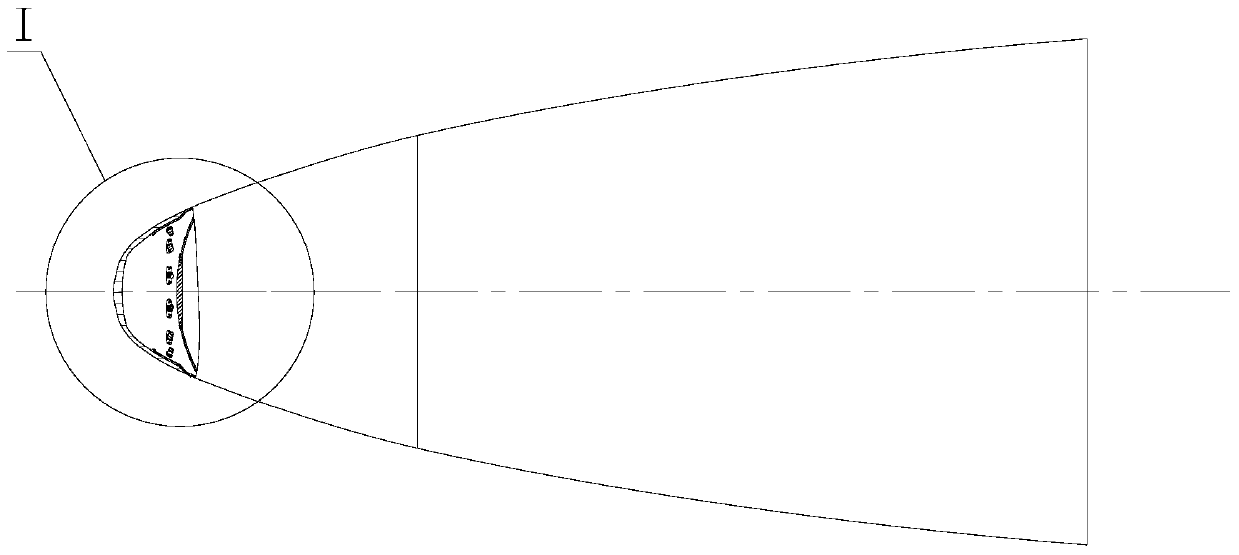

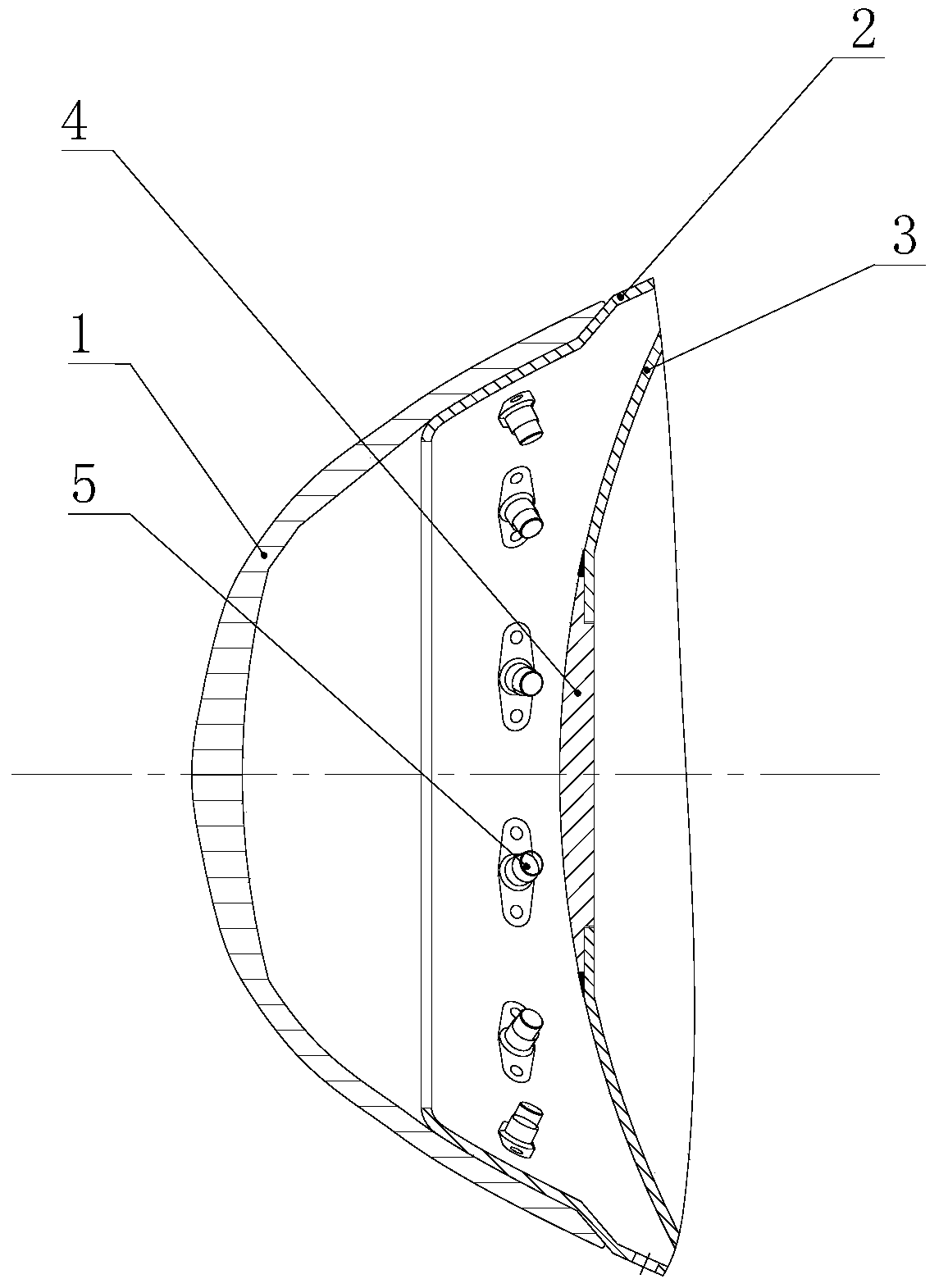

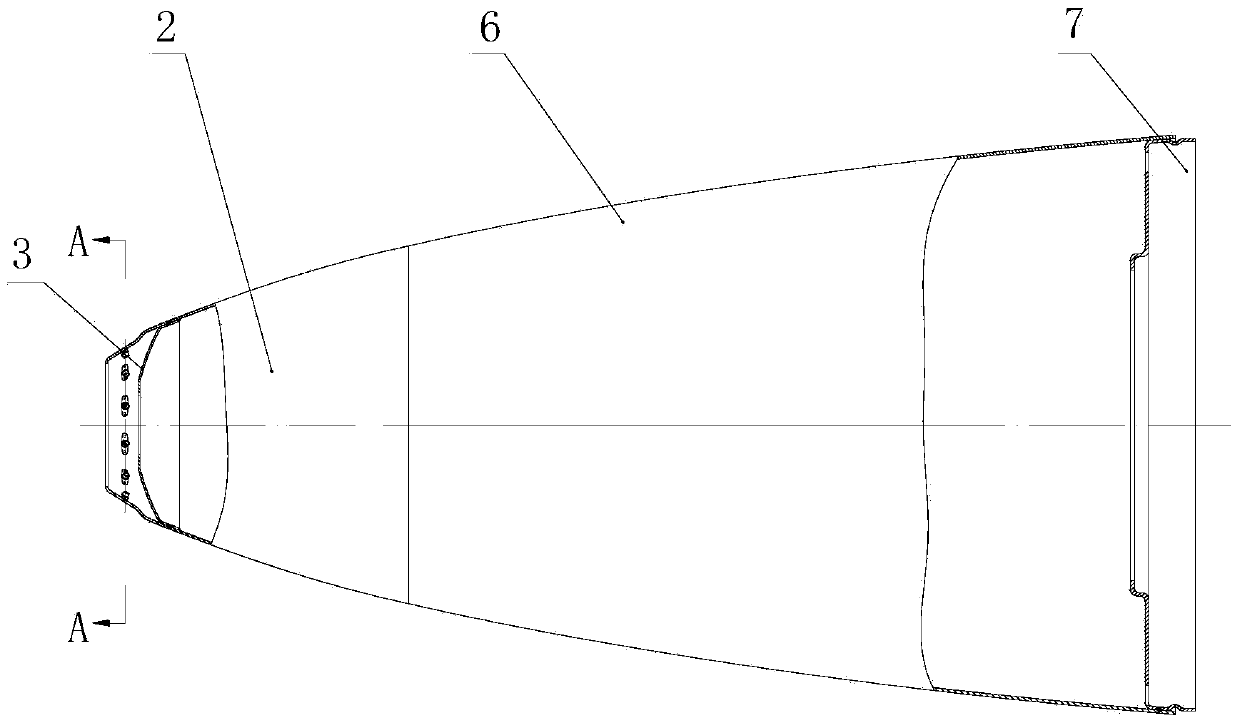

[0022] Such as figure 1 As shown, a front-edge structure of an aircraft external auxiliary fuel tank for anti-bird strike includes a fairing 1, a buffer baffle 3, a plug body 4, a front skin I2, and a front skin II6. The minimum thickness section 11 is located at the edge of the fairing, which is 5 mm to 10 mm, and the maximum thickness section 10 is located at the center of the fairing, which is 10 mm to 30 mm. 1. Connected by connectors to ensure that the assembly step difference between the front skin I2 and the outer surface of the fairing 1 is less than 1 mm; the buffer baffle 3 is located behind the fairing 1 and connected to the front skin I2 by welding; the plug body 4 is welded to the buffer baffle The hole in the middle of the plate 3 is used to isolate the front skin I2 from the fairing 1, so that the fuel in the front skin I2 and its rear structure cannot enter the fairing 1.

[0023] Specific design examples such as Figure 1 ~ Figure 3 As shown, the front edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com