An optical component storage and pick-and-place device

A pick-and-place device and technology for optical components, applied in packaging, internal accessories, transportation and packaging, etc., can solve the problems of optical component storage and pick-and-place pollution, and achieve accurate positioning, stable and reliable positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] An optical element storage and pick-and-place device of the present invention includes a storage device 1 and a clamping device 2;

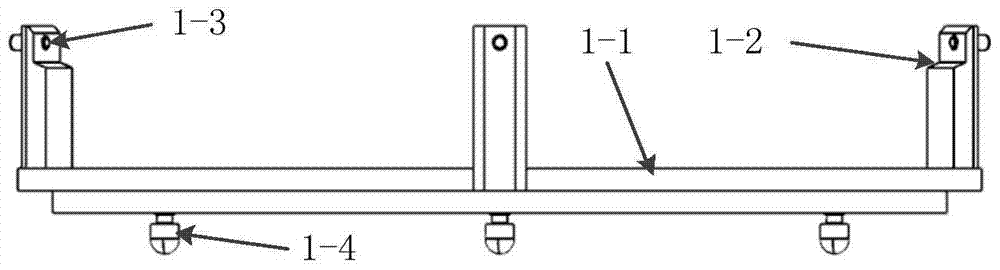

[0030] See attached figure 1 , the storage device 1 includes a base 1-1, a boss 1-2, a radial locking nail A1-3 and a ball support 1-4; the three bosses 1-2 are evenly distributed on the circumference of the On the base 1-1, a radial locking nail A1-3 is arranged radially on the upper end of each boss 1-2, and the radial locking nails A1-3 arranged on the three bosses 1-2 are on the same On the plane, three ball supports 1-4 are evenly distributed on the circumference of the lower end surface of the base 1-1;

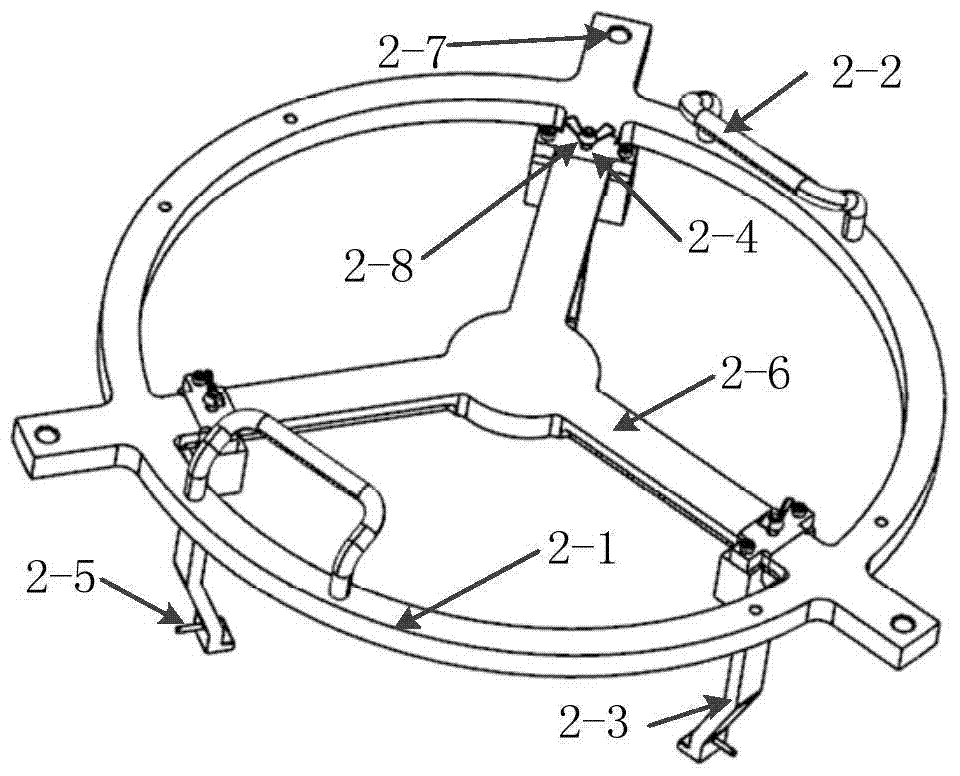

[0031] See attached figure 2 , the clamping device 2 includes a ring frame 2-1, a clamping hook 2-3, a position adjustment button 2-4, a slideway 2-6 and a thumb screw 2-8; the upper circumference of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com