Evaporated fuel supply device

一种蒸发燃料、供给装置的技术,应用在燃料中加入非燃料物质、装料系统、发动机控制等方向,能够解决无法吸引吸附罐蒸发燃料等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, the form for implementing this invention is demonstrated using drawing.

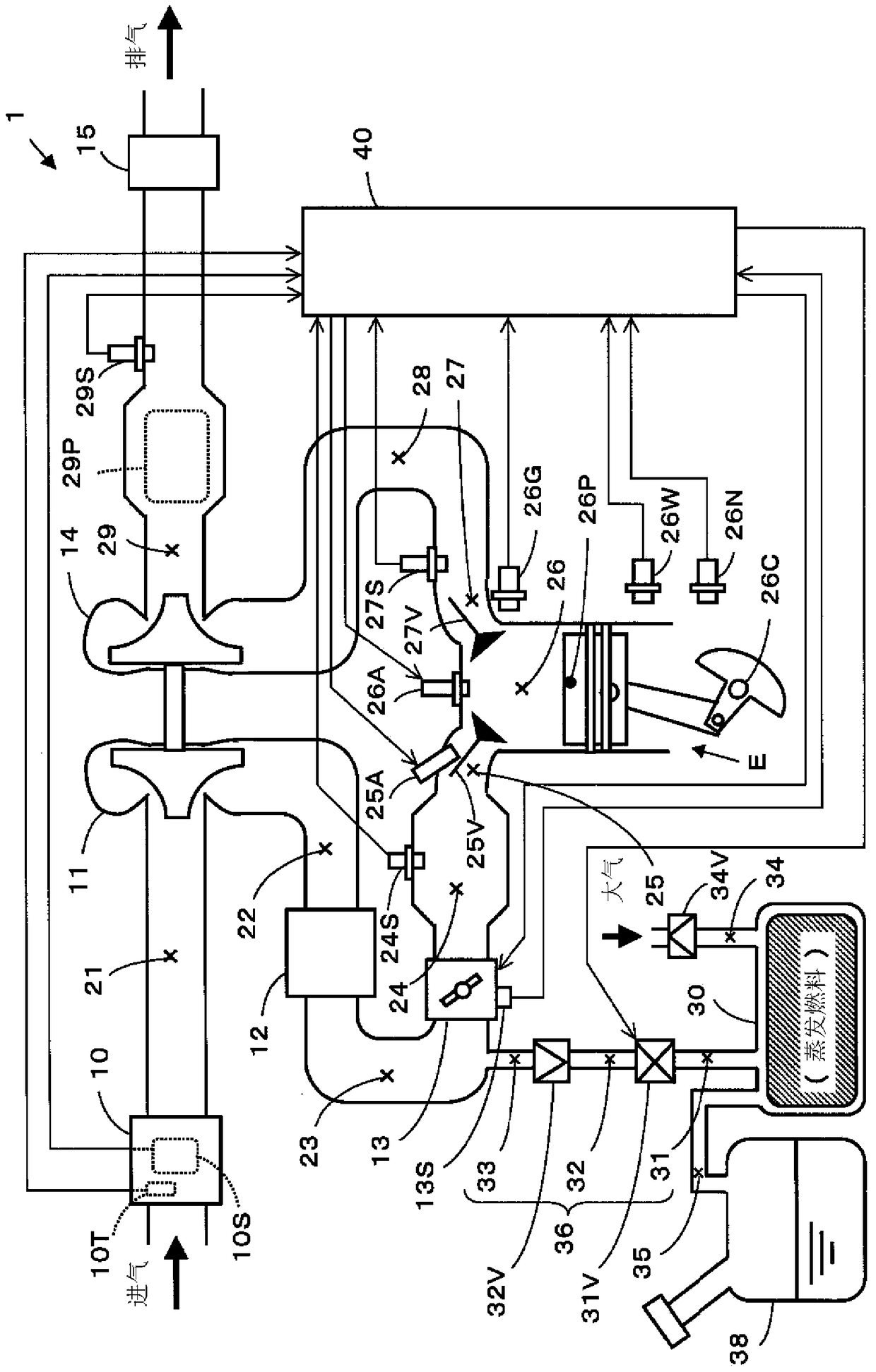

[0049] [Overall structure of the engine control system 1 including the evaporative fuel device ( figure 1 )]

[0050] figure 1 An example of the overall configuration of the engine control system of a vehicle is shown. In addition, in the description of this embodiment, as an example of an internal combustion engine, a supercharger (in figure 1 In this example, a gasoline engine with a turbocharger) will be described as an example.

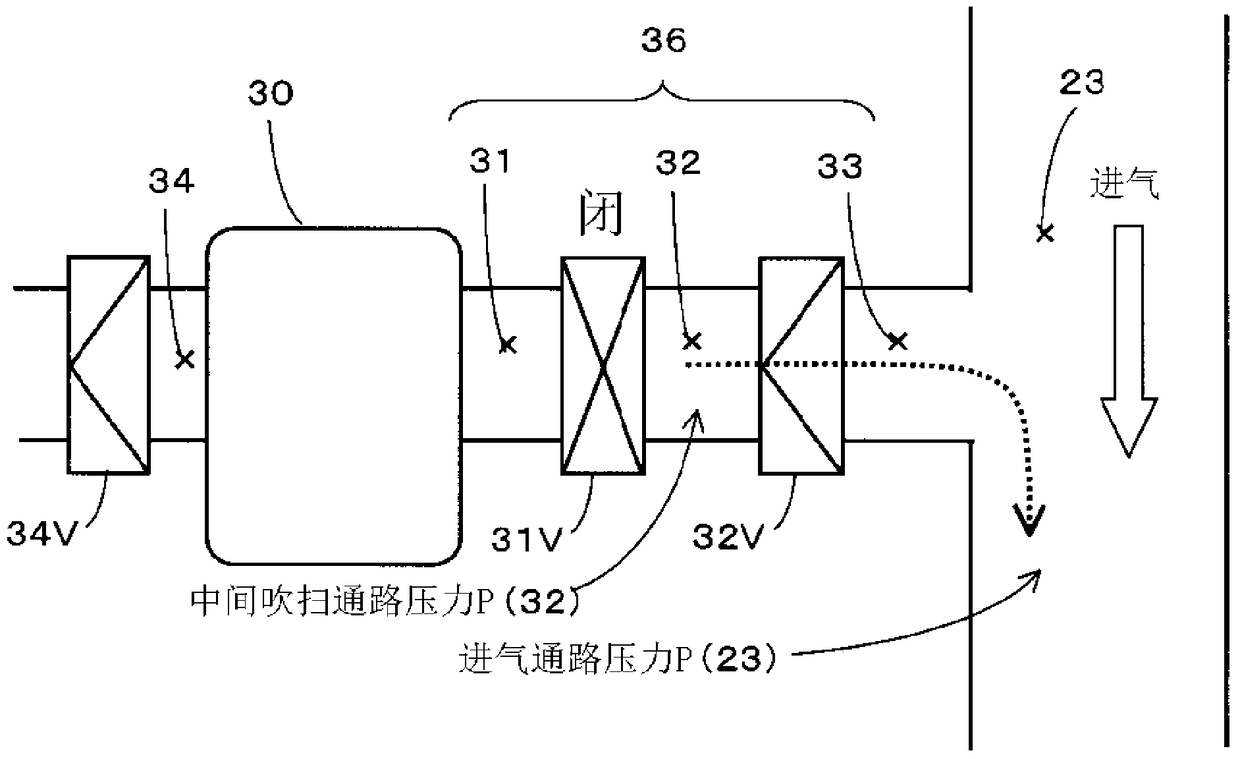

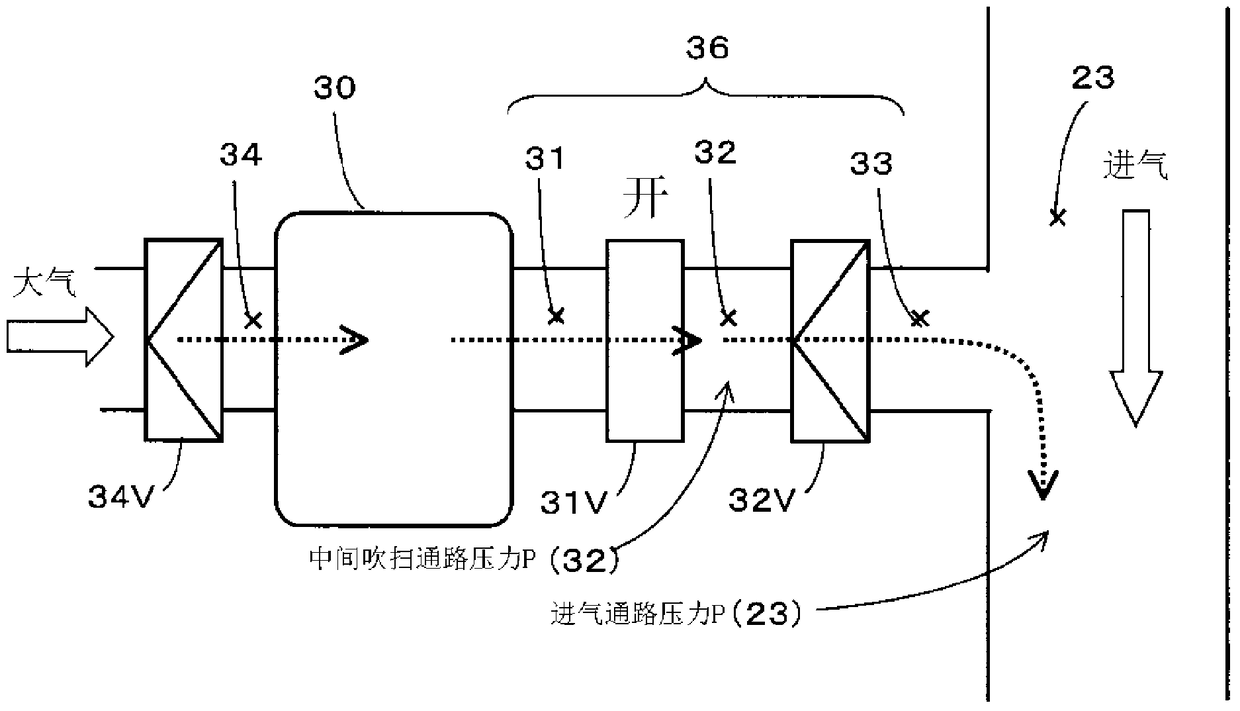

[0051] Such as figure 1 As shown, the engine control system 1 is controlled by the control unit 40, which is arranged in sequence from the intake side to the exhaust side with an air filter 10, an intake passage 21, a compressor 11, an intake passage 22, and an intercooler. 12. Intake passage 23, throttle valve 13, intake passage 24 (stabilizer box), intake manifold 25, combustion chamber 26, exhaust manifold 27, exhaust passage 28, turbine 14, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com