Vacuum pump and method of manufacturing vacuum pump

一种制造方法、真空泵的技术,应用在用于弹性流体的泵送装置的部件、泵、泵元件等方向,能够解决定子温度下降、定子逸散、空隙变小等问题,达到避免接触的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

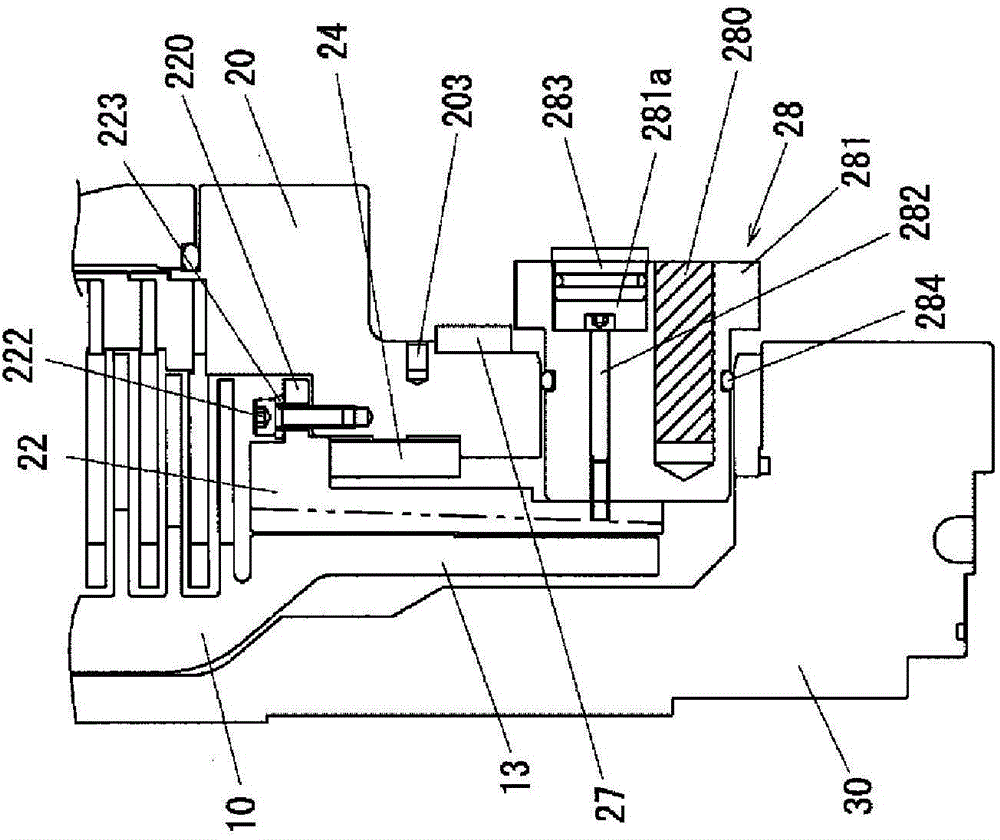

[0077] Figure 5 is a diagram showing Modification 1, and is the same as Figure 4 The case of is similarly an enlarged view of a part of the stator 22 . Figure 5 A case where positioning is performed between the inner peripheral surface of the base 20 and the outer peripheral surface of the flange portion 220 of the stator 22 is shown. In this case, the shape of the positioning member 40 may be cylindrical, or two members obtained by dividing a cylindrical member into four in the circumferential direction may be used. Hereinafter, the positioning member 40 will be described as a cylindrical shape. The outer peripheral surface 401 of the positioning member 40 and the inner peripheral surface 201 of the base 20 are in a fitting relationship (movable fitting). First, the positioning member 40 is placed on the base 20 .

[0078]Then, the stator 22 is disposed on the inner peripheral side of the positioning member 40 . The outer peripheral surface 220a of the flange portion 2...

Deformed example 2

[0080] Figure 6 It is a figure which shows the modification 2. In Modification 2, positioning is performed on the outer peripheral surface of the annular portion 202 provided on the base 20 and the outer peripheral surface of the flange portion 220 of the stator 22 . At this time, positioning is performed using a cylindrical positioning member 41 . In addition, the positioning member 41 is not limited to the cylindrical shape, and for example, a member that divides the cylindrical member into four in the circumferential direction may be used, and they may be connected by a horizontal plate. formed components. The outer diameter of the annular portion 202 and the outer diameter of the flange portion 220 are set to be the same, and the outer peripheral surfaces of the annular portion 202 and the flange portion 220 and the inner peripheral surface 400 of the positioning member 41 are in a fitting relationship (movably fitted). combine). After the stator 22 is positioned by t...

Deformed example 3

[0083] Figure 7 It is a figure which shows the modification 3. In Modification 3, the inner peripheral surface 201 of the base 20 and the inner peripheral surface 22c of the stator 22 are positioned. First, the stator 22 is disposed on the base 20 . Then, the annular positioning member 42 is arranged on the stator 22 . The outer peripheral surface 420 of the positioning member 42 is in a fitting relationship (movable fitting) with the inner peripheral surface 201 of the base 20 . On the other hand, the inner peripheral surface 421 of the annular convex portion 42c provided on the positioning member 42 is in a fitting relationship (movable fitting) with the inner peripheral surface 22c of the stator 22 . Therefore, the stator 22 is positioned with respect to the base 20 by fitting the outer peripheral surface 420 and the inner peripheral surface 201 , and the outer peripheral surface 421 and the inner peripheral surface 22 c.

[0084] The stator 22 is fixed to the base 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com