Rolling bearings with inclined running surfaces

A rolling bearing and working face technology, applied in the field of rolling bearings, can solve the problems of less needle roller support and insufficient lubricant supply, and achieve the effect of saving size, cost and size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

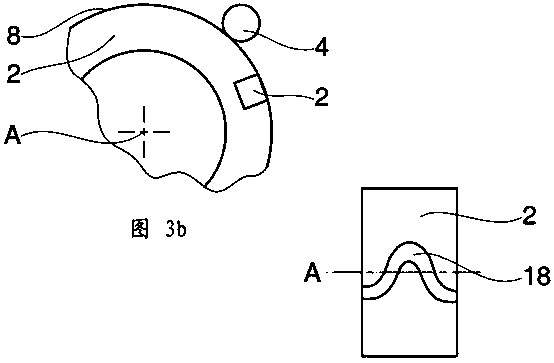

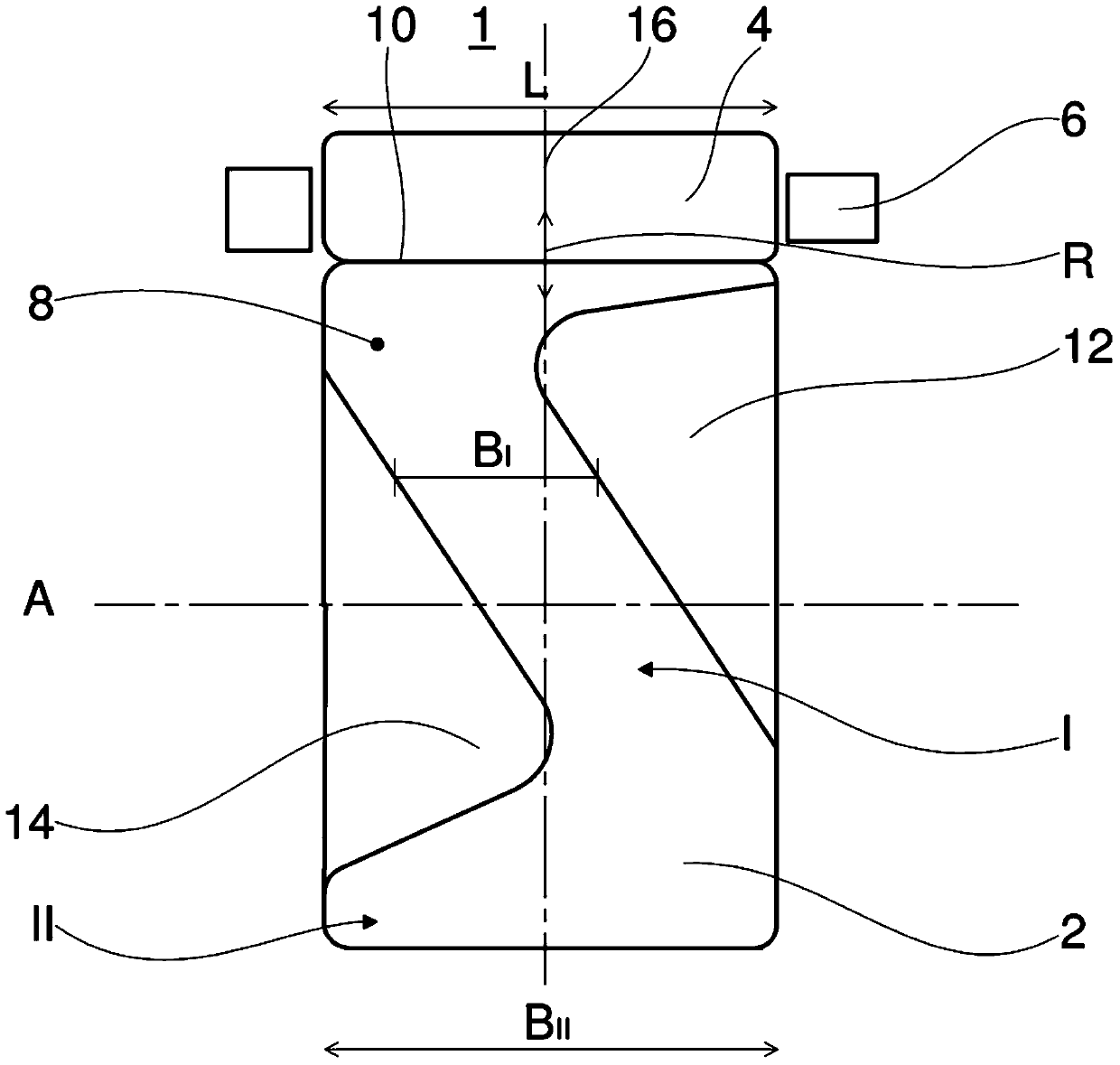

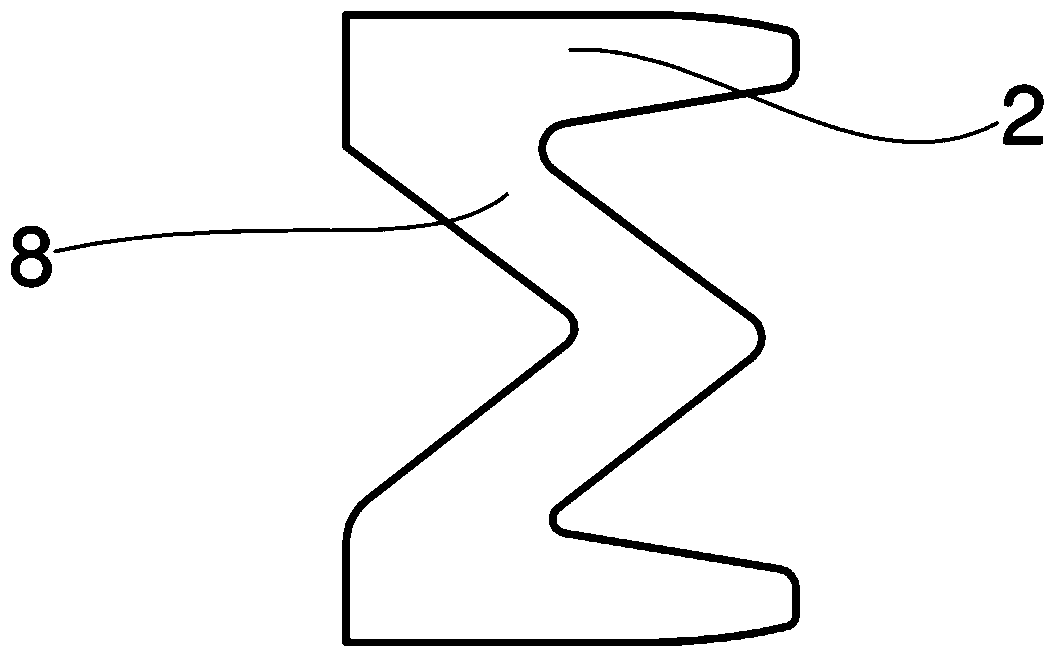

[0024] figure 1 A schematic plan view of the rolling body 1 is shown, but only the inner part 2 therein and the rolling body 4 , which are mounted in the cage 6 . An outer part (not shown) closes the rolling bearing 1 or the rolling bodies 4 radially on the outside. Also in figure 1 As shown in FIG. 1 , the inner part 2 and the not-shown outer part rotate about a common axis of rotation A, whereby the rolling bodies 4 move in a direction R on the inner part 2 . Furthermore, a running surface 8 is formed on the inner part 2 , which contacts the rolling body 4 along a straight line 10 .

[0025] Since the rolling elements 4 are configured in such a way that they contact the running surface 8 of the inner part 2 along a straight line 10 (the so-called contact line), such a rolling bearing 1 is referred to as a rolling bearing with line contact. The rolling elements themselves can have a cylindrical shape, as in the illustrated needle bearing, but it is also possible to use con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com