Heating stove oven

A technology for heating stoves and ovens, which is applied to household stoves/stoves, lighting and heating equipment, solid heating fuels, etc., and can solve problems such as the need to improve the utilization rate of heat energy, accelerate the aging rate of exhaust pipes, and consume large amounts of energy in ovens, etc., to achieve The effect of protecting the exhaust pipe, good control and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

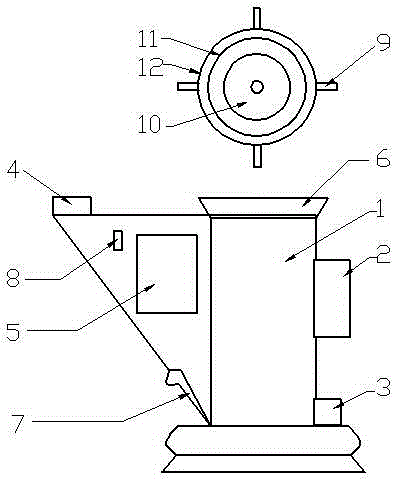

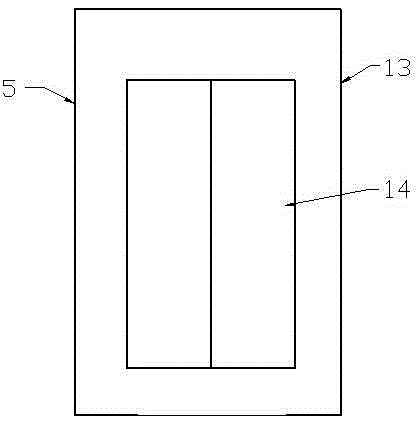

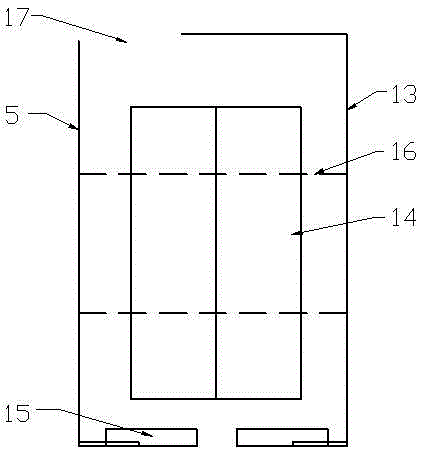

[0015] Further illustrate the implementation of the present invention with reference to the accompanying drawings (such as figure 1 , figure 2 , image 3 shown):

[0016] Option 1: A heating furnace oven, including: a furnace body 1, a firewood gate 2, an air supply port 3, a smoke pipe interface 4 and a soot valve 7, and the middle part of the right side of the furnace body 1 is a firewood gate 2 for adding firewood, The lower part on the right side is the air supply port 3, the lower part on the left side of the furnace body 1 is the soot valve 7, which is used to discharge soot, the smoke pipe interface 4 is located on the left side of the furnace body 1, and is used to discharge smoke; the furnace body 1 and the smoke pipe interface 4 is provided with an oven box 5, which is used for baking food and improving the utilization rate of heat energy. A return air switch 8 is arranged between the oven box 5 and the smoke pipe interface 4, which is used to control the smoke ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com