Detecting apparatus used for bearing groove

A technology of bearing grooves and detection devices, which is applied in the direction of measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

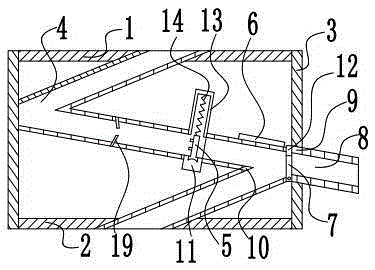

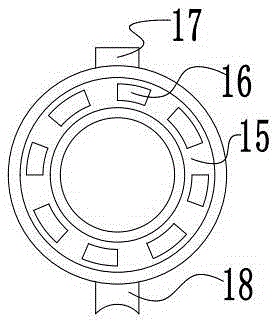

[0018] The reference signs in the drawings of the description include: top plate 1, bottom plate 2, side plate 3, spiral channel 4, channel mold 5, microcontroller 6, flap 7, discharge pipe 8, first magnet 9, second magnet 10. The first electromagnet 11, the second electromagnet 12, the bracket 13, the extension spring 14, the punch 15, the pressure sensor 16, the upper connecting seat 17, the lower connecting seat 18, and the guide piece 19.

[0019] Such as figure 1 As shown, the detection device for the bearing channel includes a circular top plate 1 and a bottom plate 2 with equal areas and an arc-shaped side plate 3 connecting the top plate 1 and the bottom plate 2 . A spiral channel 4 communicates between the top plate 1 and the bottom plate 2 . The spiral channel 4 has an inlet and an outlet, and the inlet and the outlet are located at the center of the top plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com