Scram interlocking device and system

A technology of emergency stop interlock and emergency stop switch, applied in the direction of electrical program control, digital control, etc., to achieve the effect of simple structure, fast response of emergency stop interlock and less wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The following specifically introduces an emergency stop interlock system for CNC machine tools.

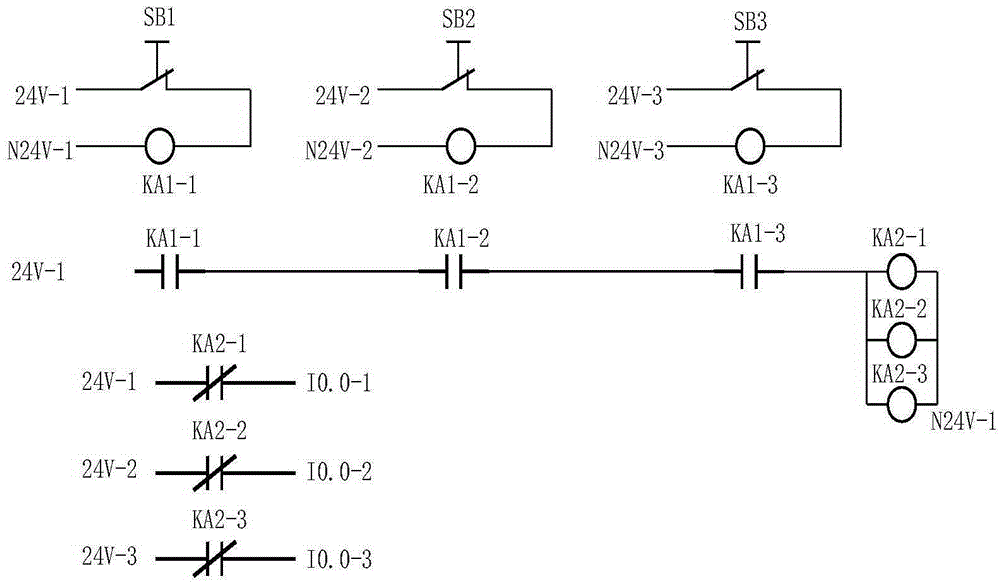

[0015] Such as figure 1 As shown, for the three CNC machine tools and the corresponding emergency stop interlock devices, the emergency stop interlock devices include: each machine tool is equipped with an emergency stop signal generation circuit, that is, the emergency stop signal generation circuit of the first CNC machine tool is controlled by the emergency stop signal generation circuit. The stop switch SB1 and the detection relay coil KA1-1 are formed in series, the emergency stop signal generating circuit of the second CNC machine tool is formed by the emergency stop switch SB2 and the detection relay coil KA1-2 in series, the emergency stop signal input circuit of the third CNC machine tool The emergency stop switch SB1 and the detection relay KA1-3 are connected in series, and the power supply for the three emergency stop signal generating circuits is 24V. Three co...

Embodiment 2

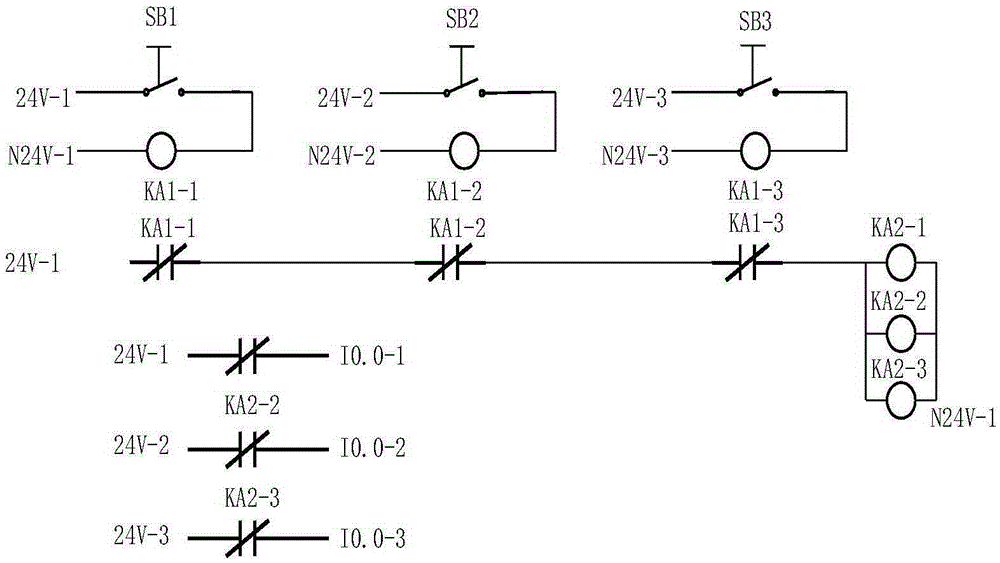

[0018] Above-mentioned embodiment 1 has provided the embodiment that the emergency stop switch is a normally closed switch, and the contact of the detection relay is a normally open contact. As other embodiments, the emergency stop switch can also be a normally open switch, and the contact of the detection relay is Normally closed contacts, such as figure 2 As shown, the only difference from Embodiment 1 is that the emergency stop switch is a normally open switch, and the contacts of the detection relays KA1-1, KA1-2 and KA1-3 are normally closed contacts.

[0019] When the assembly line is working normally, each CNC machine tool is running normally. At this time, the emergency stop switch is in the disconnected state, the detection relays KA1-1, KA1-2, and KA1-3 are in the power-off state, and the control relays KA2-1, KA2-2 , KA2-3 is in the energized state, the normally closed contacts of the detection relays KA1-1, KA1-2, KA1-3 are closed, and the normally closed contacts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com