Manufacturing method of RFID label

A technology of RFID tags and manufacturing methods, applied in the direction of record carriers used in machines, instruments, computer parts, etc., can solve problems such as low production efficiency, difficulty in producing contour lines, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples illustrate the possible implementation forms of the present invention, but are not intended to limit the scope of protection of the present invention.

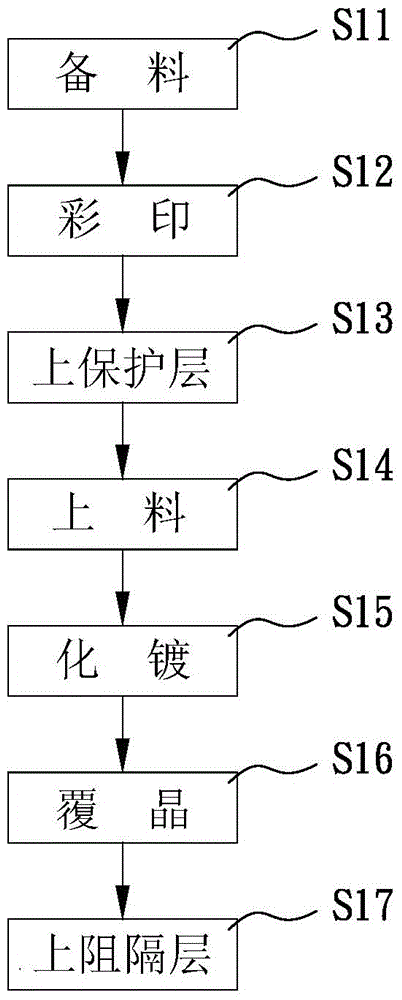

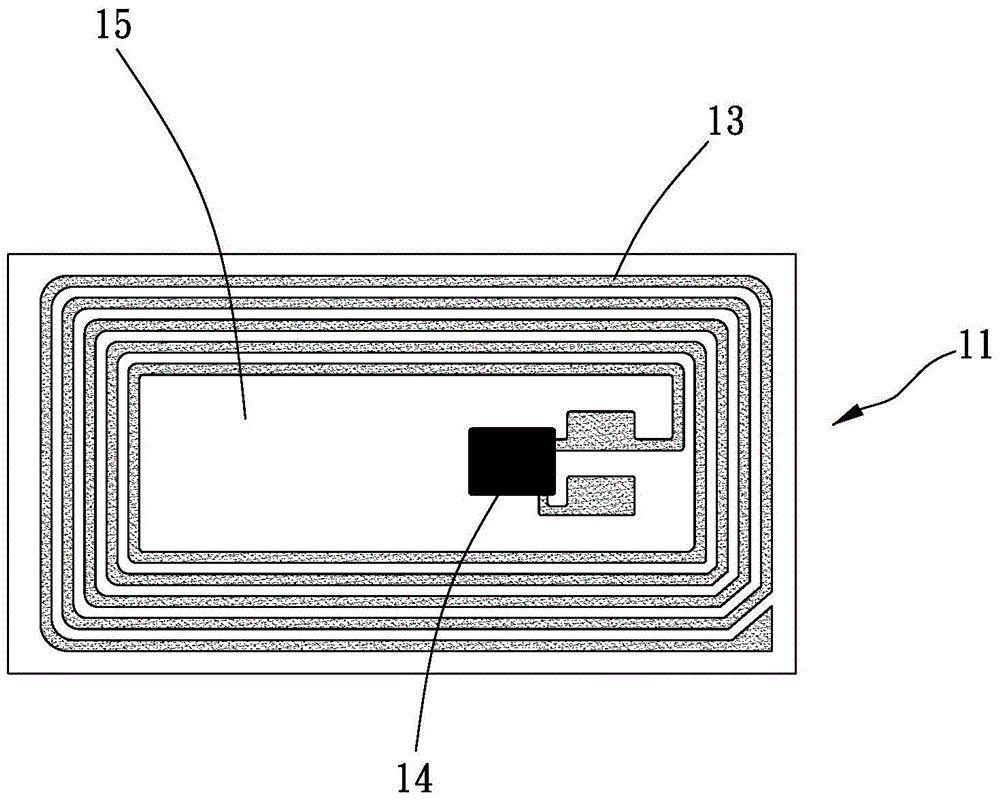

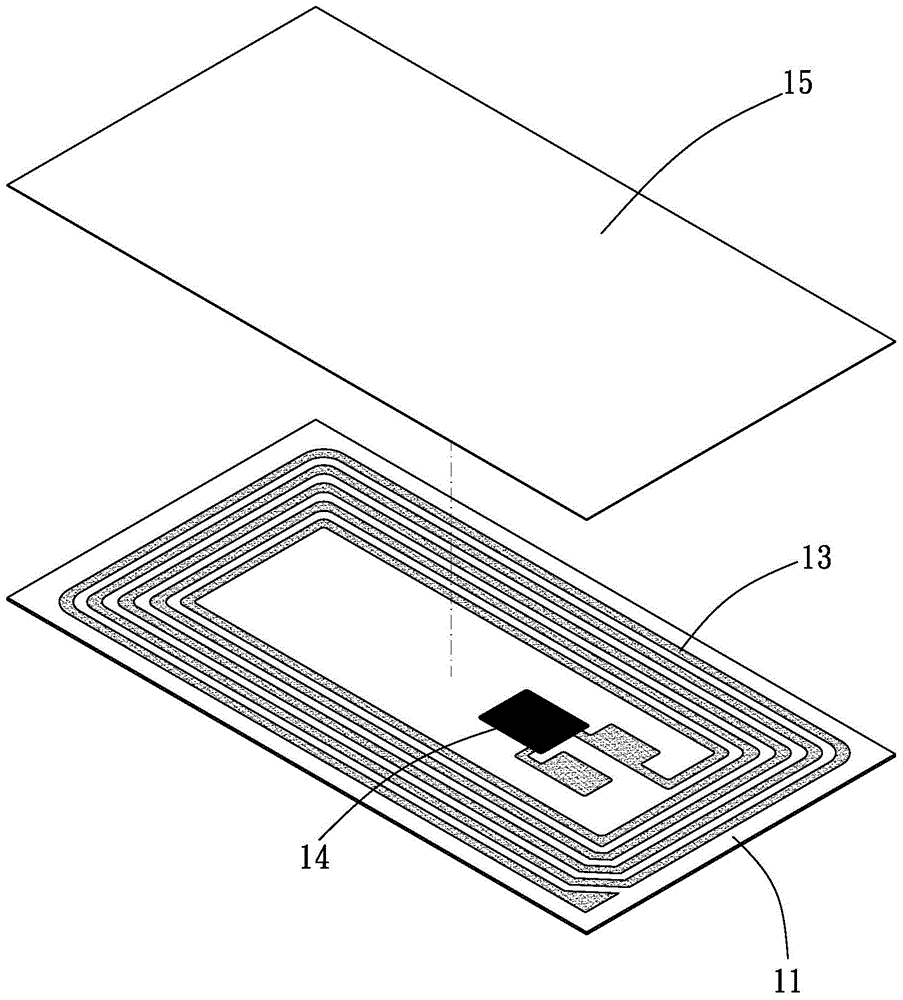

[0028] Please refer to Figure 1 to Figure 4 , the present invention provides a kind of RFID label manufacturing method, comprises the following steps:

[0029] Preparation S11: prepare a substrate 11, the substrate 11 is made of PET, PP, ABS, PC, PS, PMMA or TYVEK and has a first surface and a second surface opposite to each other.

[0030] Color printing S12 : performing color printing on the first surface of the substrate 11 to form a color printing layer 12 .

[0031] Upper protective layer S13 : attaching a transparent protective layer on the first surface of the substrate 11 to cover the color printing layer.

[0032] Material loading S14: attach a catalytic ink to the second surface of the substrate 11 to form an ink layer with a specific pattern. In this embodiment, the catalytic ink is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap