Motor stator

A motor stator and stator block technology, applied in the direction of magnetic circuit static parts, magnetic circuit shape/style/structure, etc., can solve the problems of complex processing and assembly, complex winding processing and assembly steps of stator block 91, and lengthy production time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to make the above-mentioned and other purposes, features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

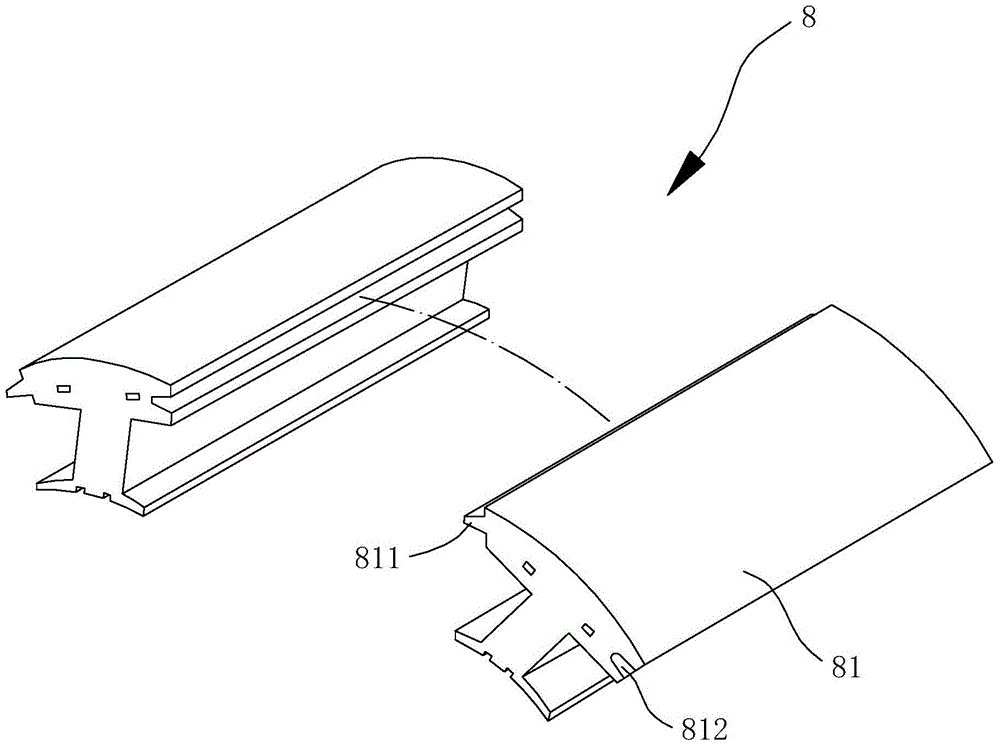

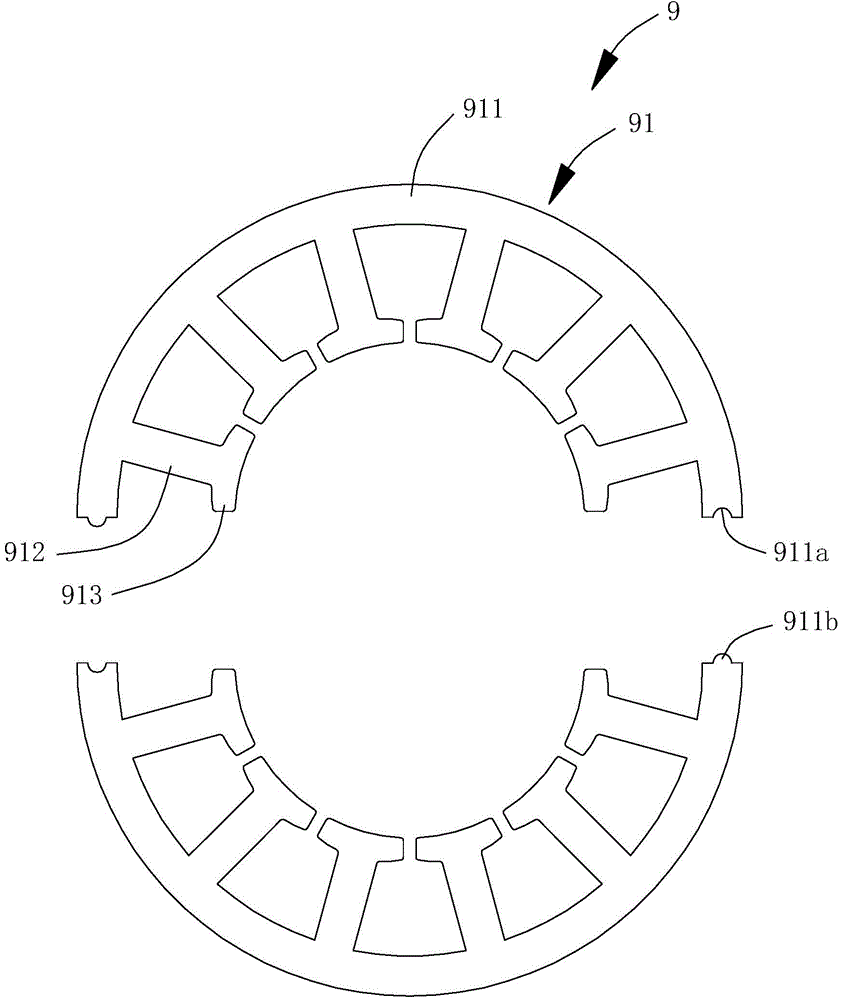

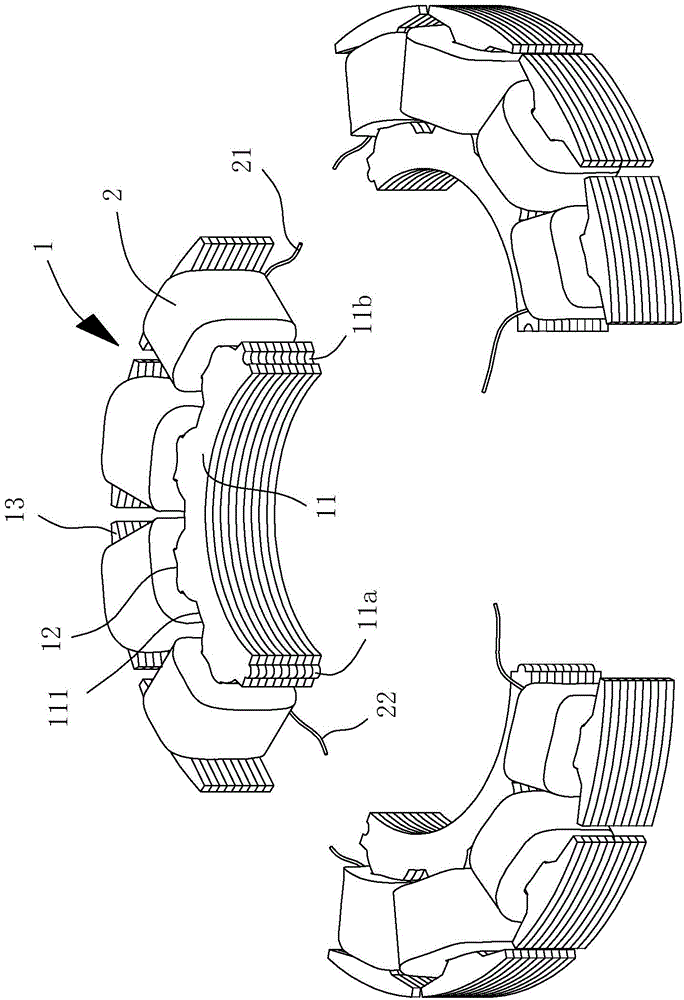

[0064] Please refer to image 3 and Figure 4 Shown is the motor stator of the first embodiment of the present invention, the motor stator includes several stator blocks 1, each of which is wound with a coil 2, and the several stator blocks 1 can be assembled and combined with each other. Each stator block 1 includes a yoke portion 11 and several poles 12. Specifically, for any stator block 1, the stator block 1 includes a single yoke portion 11, and the several poles 12 are respectively connected to The yoke part 11 is connected with a pole piece 13 at the end of each pole post 12 away from the yoke part 11 . The yoke portion 11 preferably has an arc surface 111, and the plurality of pole columns 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com