Vacuum encapsulation device for high-power high-packaging-density electronic products, and encapsulation method thereof

A technology of electronic products and assembly density, applied in the direction of sealing shell, cooling/ventilation/heating transformation, etc., can solve the problems of high void rate, difficult to fill products, product failure, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

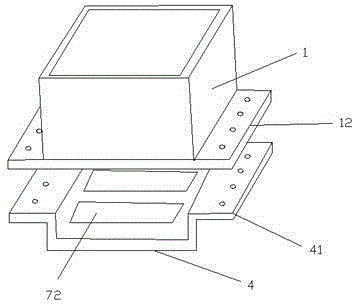

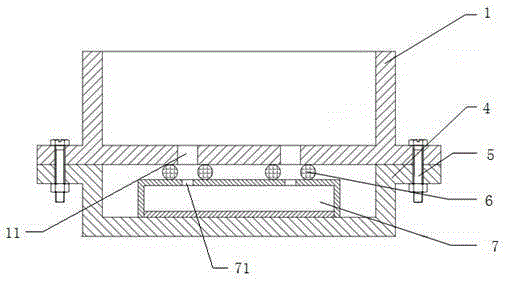

[0019] Such as Figure 1~3 As shown, the vacuum potting device for high-power and high-density electronic products in this embodiment includes a potting rubber tank 1 and a product placement tank 4 installed on the lower side of the potting rubber tank 1 and used for placing electronic products 7 , the top opening of the potting rubber tank 1, the bottom of which is provided with a plurality of openings 11 corresponding to the potting holes 71 on the electronic product 7, and the openings 11 and the potting holes 71 are mutually sealed by the rubber elastic ring 6 fixed.

[0020] Such as figure 2 As shown, the potting compound tank 1 is a cuboid structure with an open top, and the two sides of the cuboid have a first connecting plate 12 extending horizontally outward along its bottom surface. The cross section of the product placement tank 4 is U-shaped, and the U-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com