Blind plug type assisting handle mechanism for multi-pin type port control cabinet cases

A technology of interface control and control cabinet, which is applied in the direction of component plug-in combination, circuit layout on support structure, elastic/clamping device, etc. Smooth plugging and other issues, to achieve the effect of improving installation and maintenance performance, simple and convenient use, and stable plugging force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

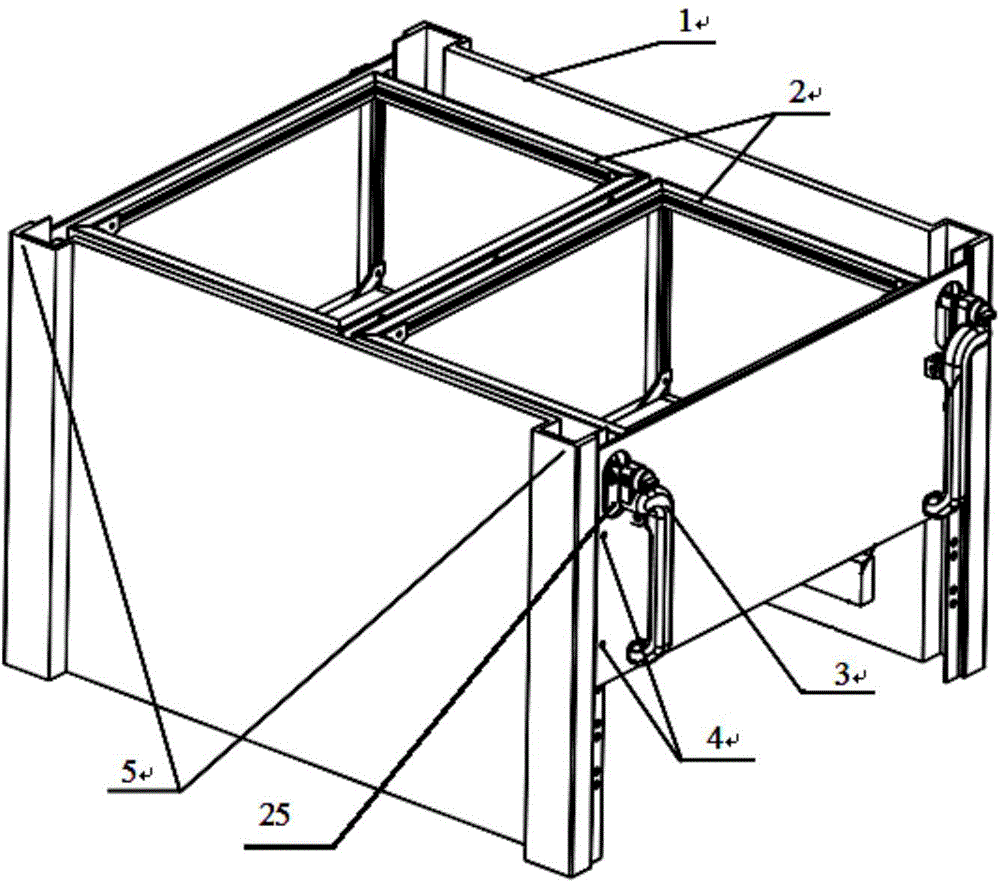

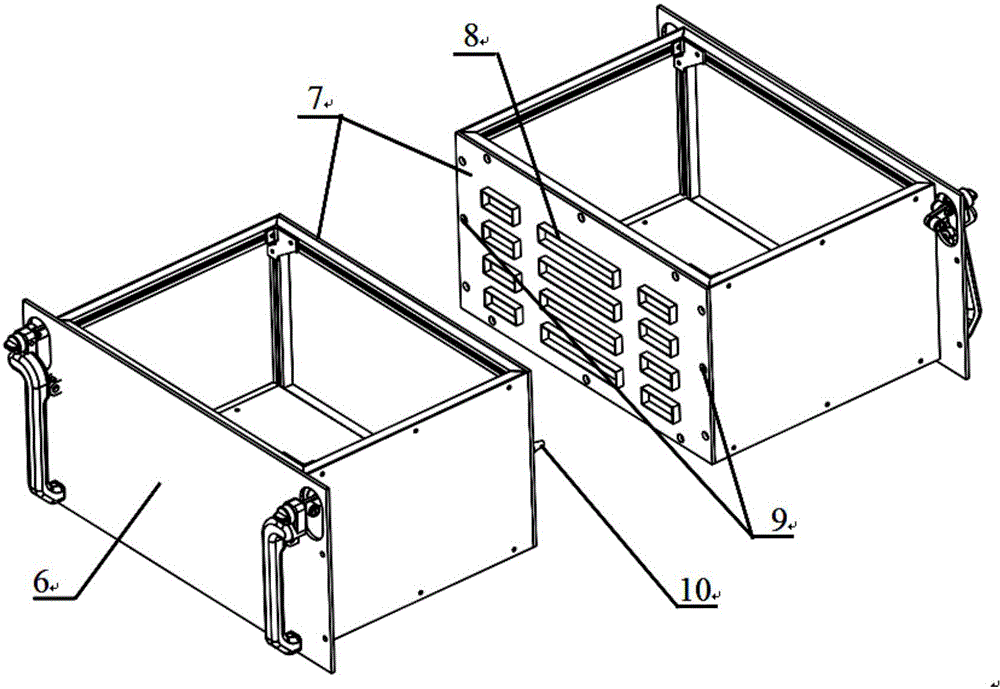

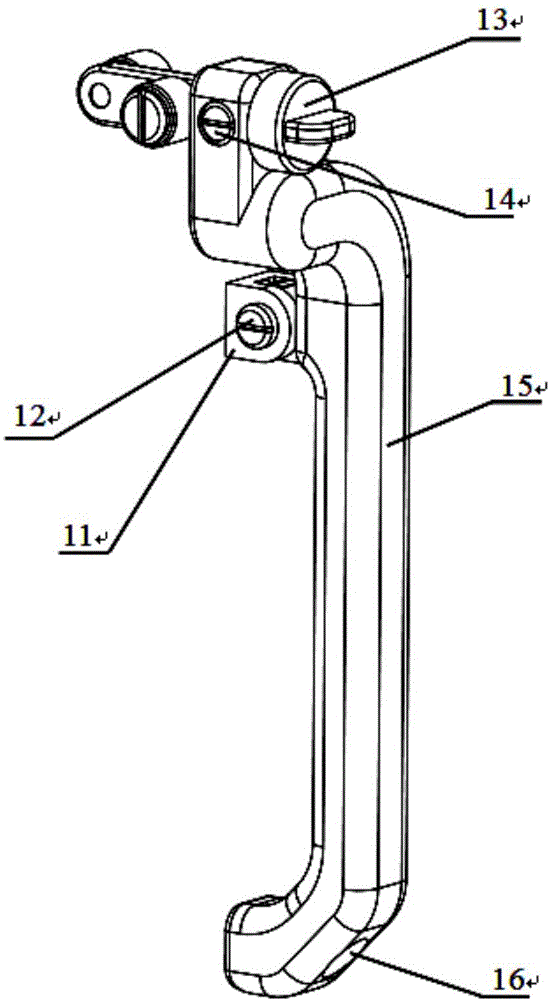

[0032] Such as figure 1 , 2 , 3, and 4, the present invention provides a multi-pin interface control cabinet chassis blind plug-in power-assisted handle mechanism, including a left-side plug-in and pull-out handle mechanism 3 symmetrically installed at both ends of the front panel 6 of the multi-pin interface chassis and the right side plug-and-pull handle mechanism 17, a control cabinet 1 is installed outside the front panel 6 of the multi-pin interface cabinet, and the control cabinet 1 is provided with a vertical beam 5 of the control cabinet at a position in contact with the front panel 6 of the multi-pin interface cabinet, wherein, The structure of the left-hand plug-and-extraction-assisting handle mechanism is the same as that of the right-side plug-and-extraction-assisted handle mechanism 17 , and the left-side plug-and-extraction-assisting handle mechanism i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com