Natural heat dissipating layout of electrical or electronic heating device

A heat-generating device and natural heat dissipation technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve problems such as unreasonable layout of power modules and temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

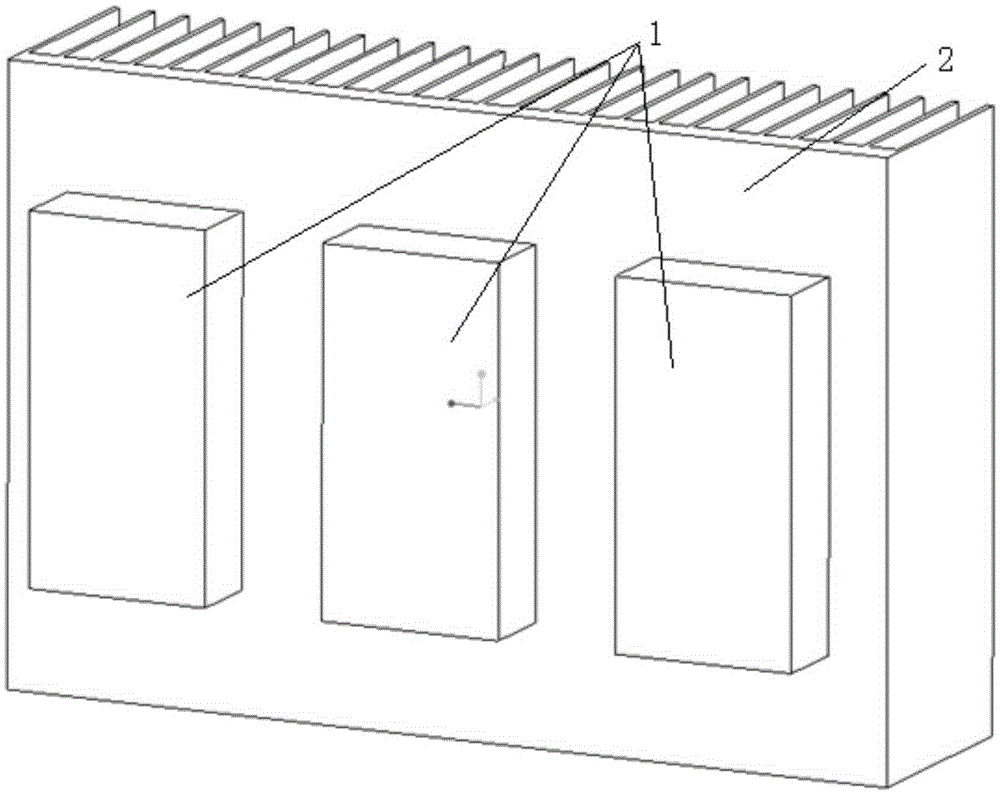

[0016] The three heat source power modules dissipate heat through the natural cooling radiator. The length, width and height of the radiator are 40*520*110mm, the length, width and height of the heat source power module are 66*32*10mm, and the heat loss is 108W.

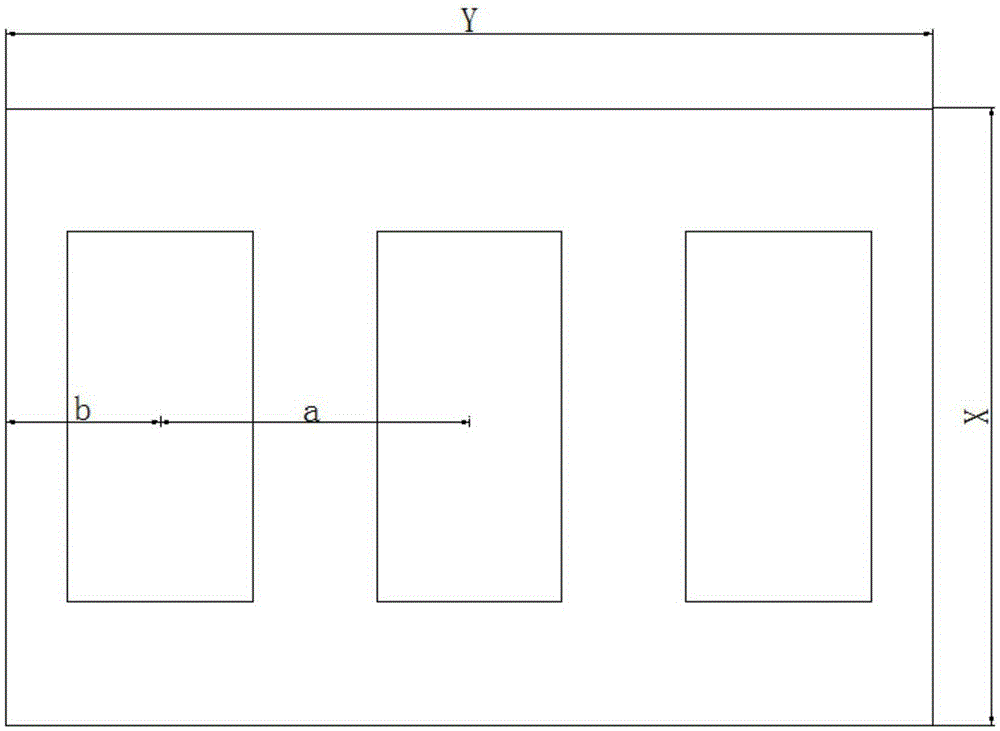

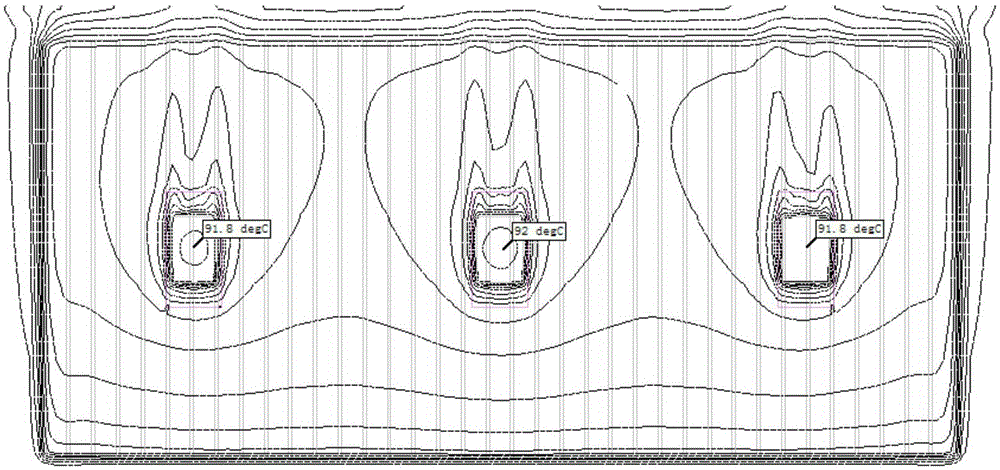

[0017] 1. When the layout of the heat source power module meets the layout requirements of the present invention, that is, a=520 / 3, b=520 / 6: the temperature isotherm diagram of the heat source is obtained through the simulation software, such as image 3 Shown: The maximum temperature of the heat source power module is 92 degrees Celsius, and the temperature difference between the three heat source power modules is 0.2 degrees Celsius.

[0018] 2. When the layout of the heat source power module does not meet the design requirements of the present invention:

[0019] The first case: if a>520 / 3b Figure 4 Shown: The maximum temperature of the heat source power module is 93 degrees Celsius, and the temperature difference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com