Winding engine for elevator and elevator device

A hoist and elevator technology, which is applied in the direction of elevators, transportation and packaging in buildings, can solve the problems of miniaturization and thinning of the hoist, low heat-resistant temperature of the encoder, etc., and achieve miniaturization, space reduction, and realization of The effect of thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

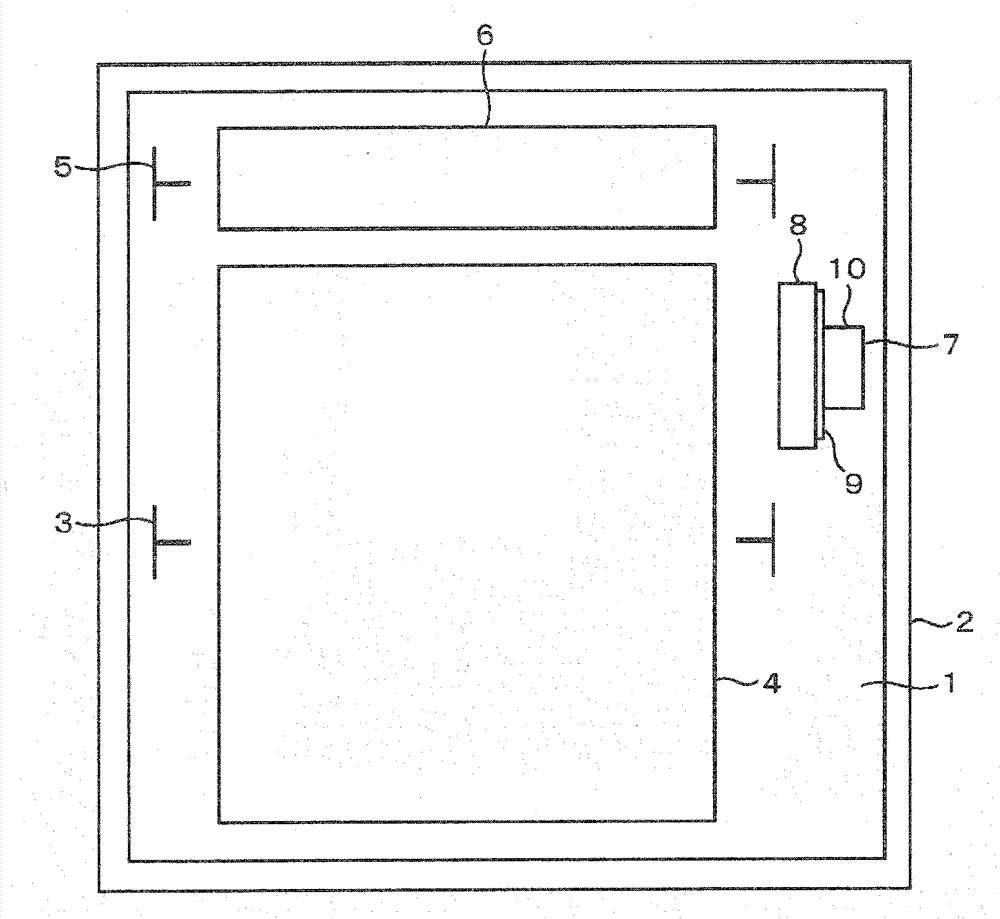

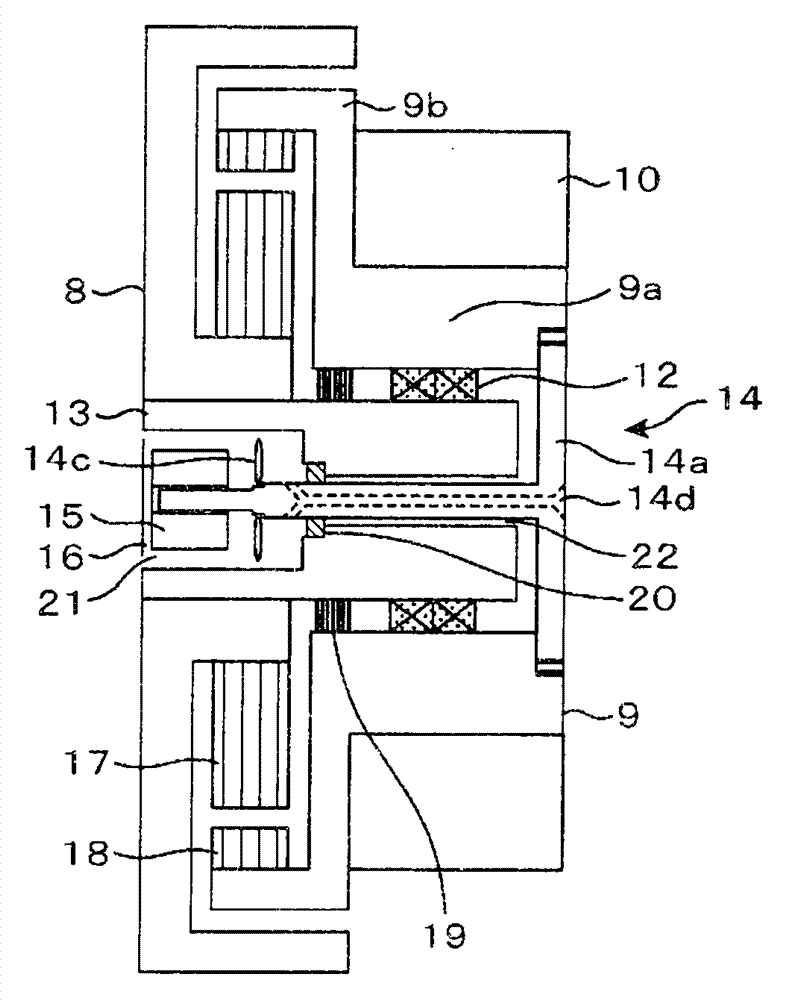

[0052] figure 1 It is a plan view of the hoistway of the elevator without a machine room according to one embodiment of the present invention. Such as figure 1 As shown, in the hoistway 1, an elevator car 4 guided up and down by a pair of elevator car side guide rails 3 fixed on the hoistway wall 2 and a counterweight guided up and down by a pair of counterweight side guide rails 5 are arranged. 6, and a winch 7 is arranged between the elevator car 4 and the hoistway 2. This winch 7 is made of frame body 8, the rotating frame that is cylindrical shape that is positioned at frame body 8 hoistway wall 2 sides, namely brake drum 9 and the sheave 10 that is supported by brake drum 9, brake drum 9 and sheave 10 have the same axis of rotation and are fixed to rotate synchronously with each other.

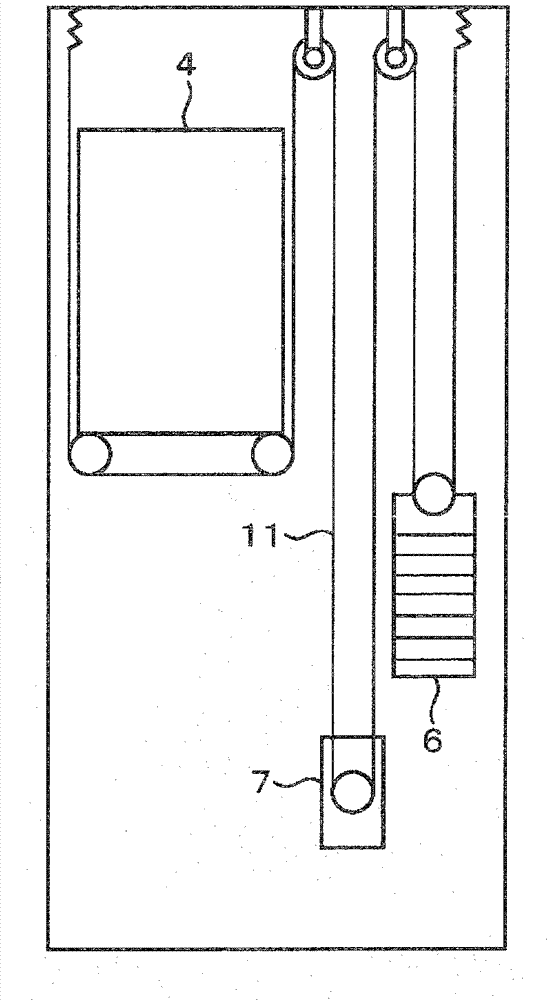

[0053] figure 2 It is a schematic layout diagram in the hoistway of an elevator without a machine room according to an embodiment of the present invention. Such as figure 2 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com