High-efficiency demisting device

A demister device, high-efficiency technology, applied in the direction of combination device, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of difficult fog droplet removal, difficult cleaning, short flue gas flow path of demist device, etc., to reduce Investment cost, strong adaptability, and the effect of improving classification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better understand the purpose, structure and function of the present invention, a high-efficiency demisting device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

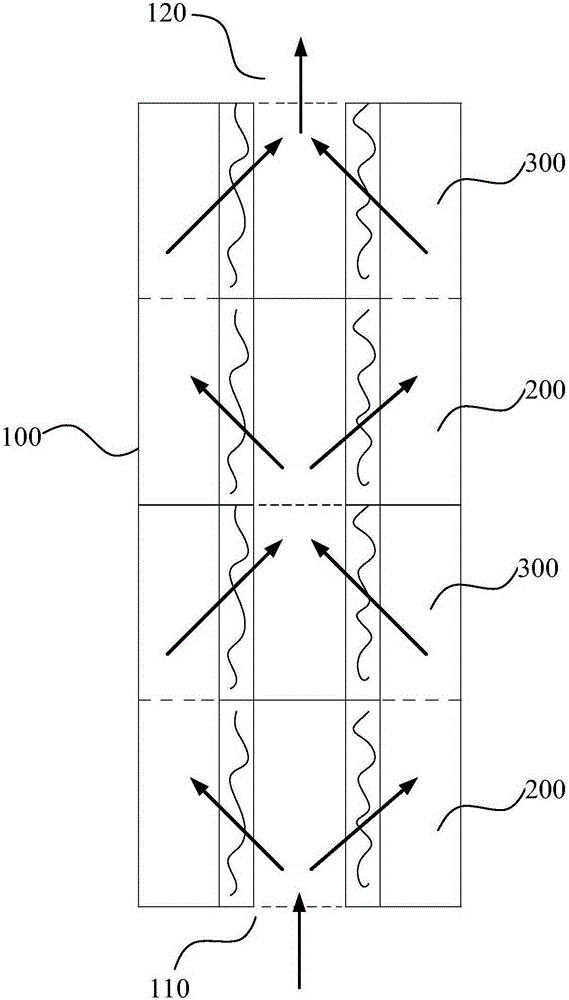

[0016] Such as figure 1 As shown, the high-efficiency demisting device of the present invention includes a housing 100, wherein a smoke inlet 110 and a smoke outlet 120 are arranged on the housing 100, and a first demisting assembly 200 and a second demisting assembly 200 are arranged inside the housing 100 The assembly 300, the first defogging assembly 200 and the second defogging assembly 300 are connected in sequence to form a curved air flow channel inside the housing, and the curved air flow channel communicates with the smoke gas inlet 110 and the smoke gas outlet 120 on the housing 100, To form a flue gas demisting channel.

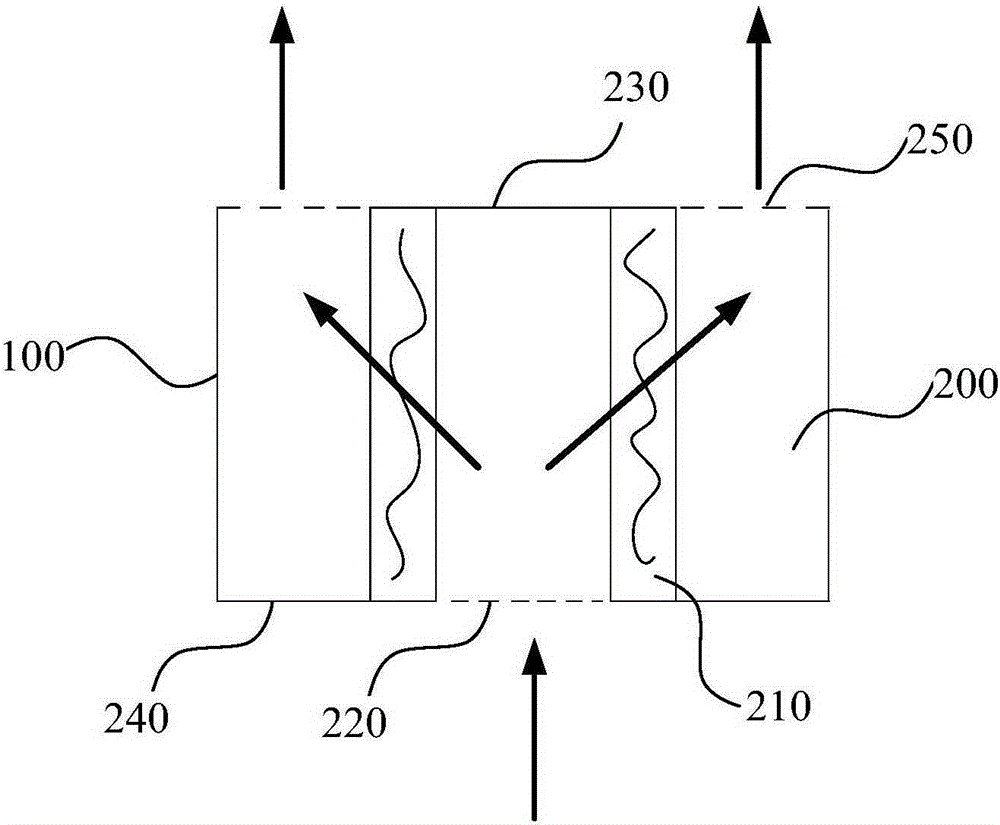

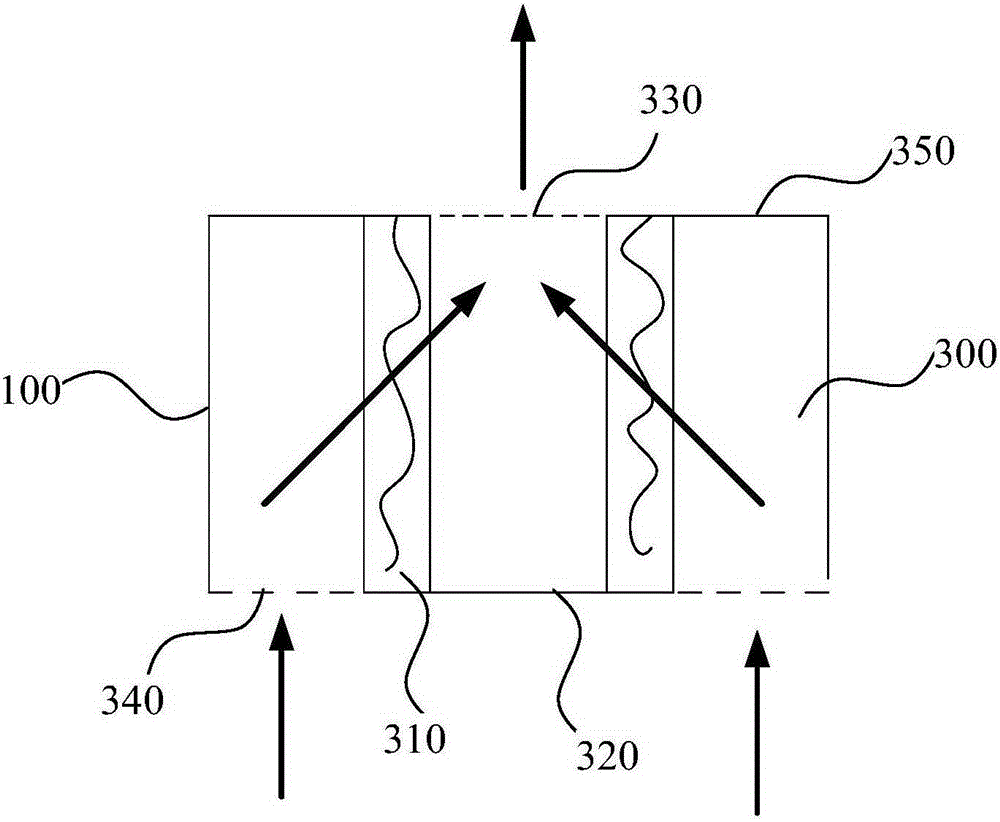

[0017] further, such as figure 2 As shown, the first demister assembly 200 includes a first demis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com