Small automatic stirrer

A mixer and automatic technology, applied in the direction of mixer accessories, mixers, dissolving, etc., can solve the problems of inconsistent quality, high labor intensity, and inability to mix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

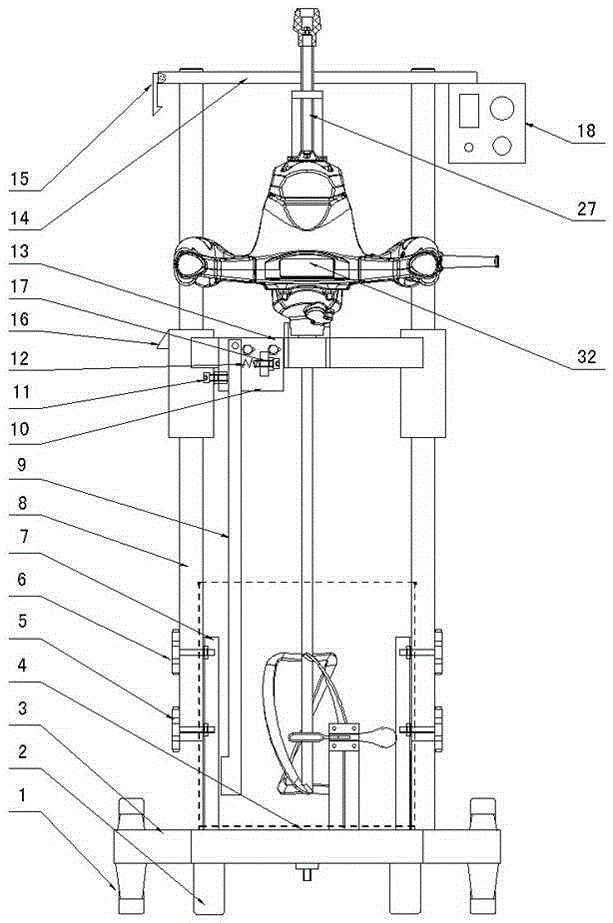

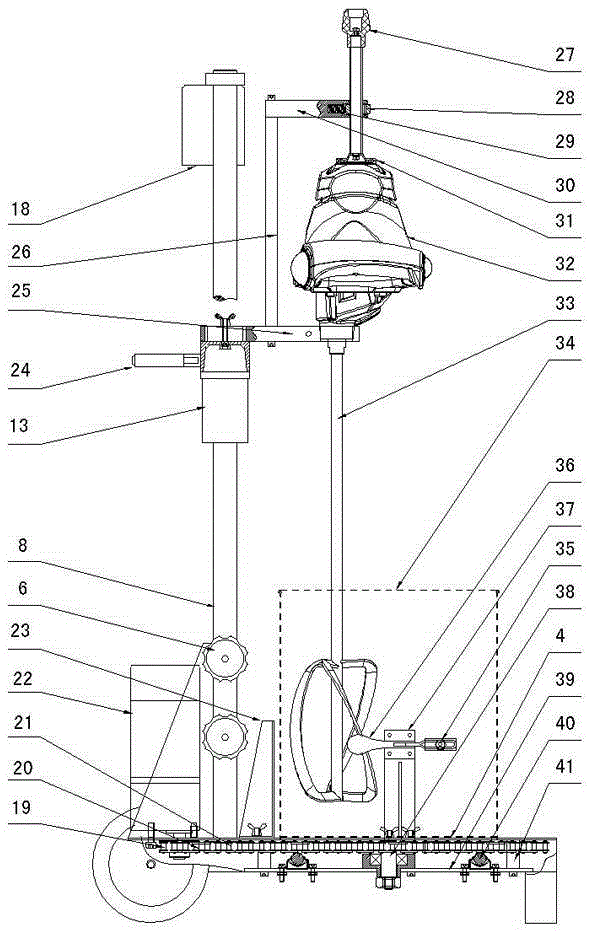

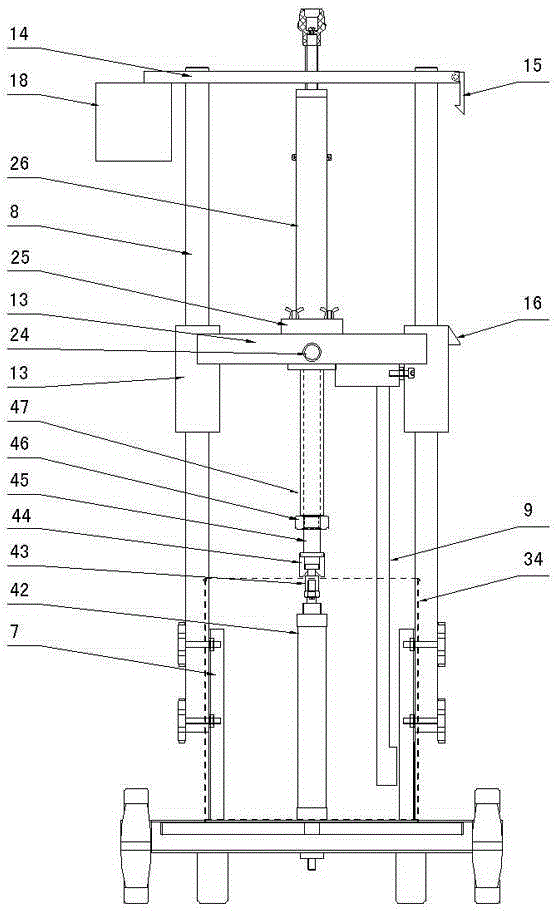

[0021] Figure 1 to Figure 5 As shown, the invention creates a specific embodiment of a small-sized automatic mixer, which includes a machine base 3, left and right guide columns 8, guide column connecting plates 14, agitator 32, mixing bucket 34, controller 18, and a lifting mechanism. The lifting mechanism described above includes a lifting cylinder 42, an adjusting rod, and a moving crossbeam 13. The lifting cylinder 42 is fixed on the machine base 3, and the moving crossbeam 13 is arranged on the left and right guide columns 8 through a linear bearing to slide up and down. The fixed end of the adjusting rod is fixed On the moving crossbeam 13, its movable end can be quickly disassembled and fastened to the piston rod of the lifting cylinder 42. The moving crossbeam 13 is fixed with an agitator holder 25, and the agitator 32 is fixedly arranged on the agitator holder 25. The stirring paddle 33 of the stirrer 32 extends into the mixing barrel 34, the controller 18 controls t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com