Aluminum Extrusion Decorative Pillar Mold

A decorative column and aluminum alloy technology, applied in the field of aluminum alloy profiles, to achieve good texture, improve the rendering of the environment atmosphere, and improve the effect of decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

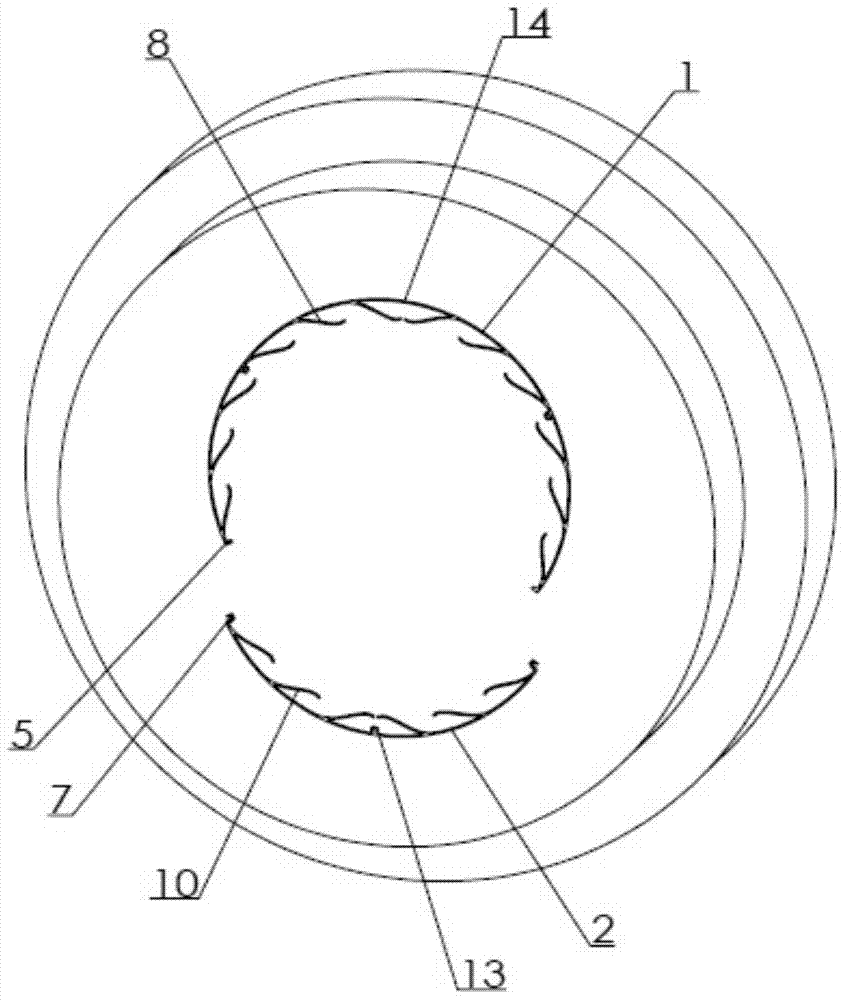

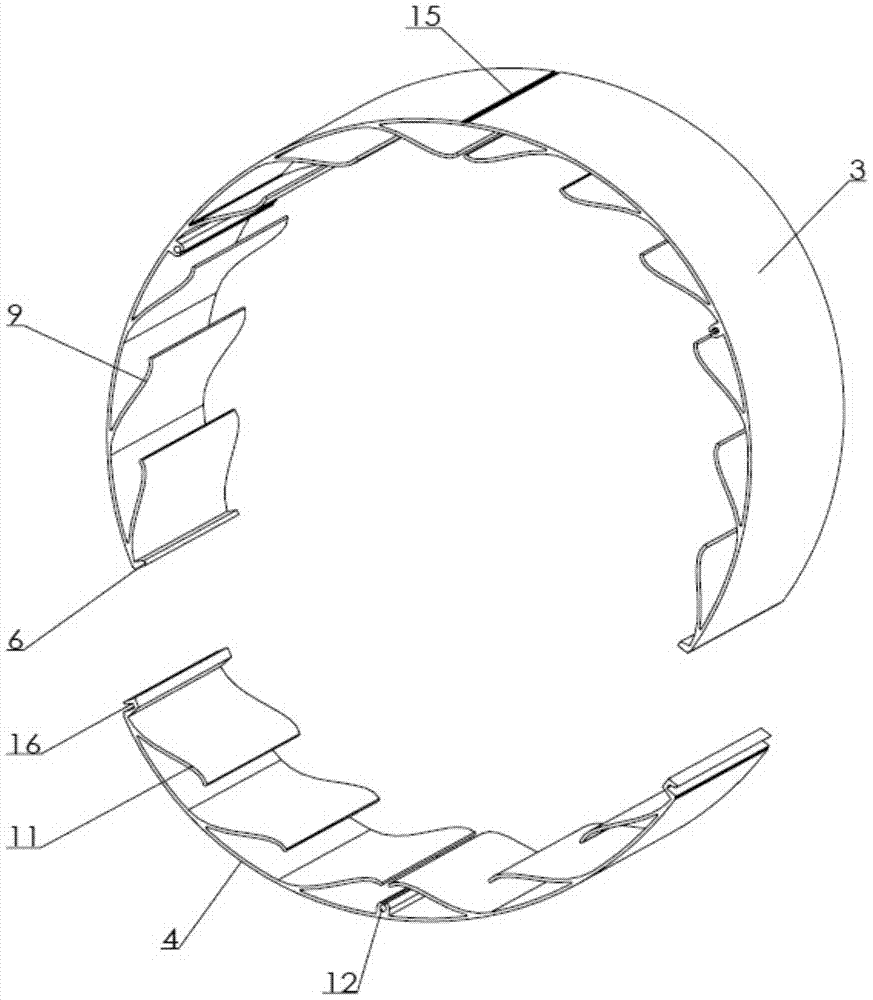

[0011] Examples of the present invention figure 1 , 2 As shown, the aluminum alloy extrusion decorative column mold includes a large arc-shaped side wall runner 1 and a small arc-shaped side wall runner 2 with an arc-shaped cross section, which is used to extrude a large arc-shaped side wall 3 and a small arc-shaped Side wall 4, the large arc side wall flow channel and the small arc side wall flow channel have the same diameter in the cross-sectional arc trajectory, the small arc side wall flow channel is located below the large arc side wall flow channel, and the large arc side wall flow channel The center angle of the arc track of the channel cross section is 240 degrees, the center angle of the arc track of the small arc side wall channel cross section is 120 degrees, and the edge of the large arc side wall channel is provided with an undercut flow pointing to the center of the circle. The channel 5 is used to extrude the barb 6 at the longitudinal edge of the large arc-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com