A laser engraving machine for processing wooden combs and a method for engraving wooden combs

A laser engraving machine and wood comb technology, applied in the field of laser engraving machines, can solve the problems of affecting the processing effect, reducing the temperature of non-metallic materials, and poor fixing effect, so as to improve the processing quality and yield, improve the degree of automation, fix good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

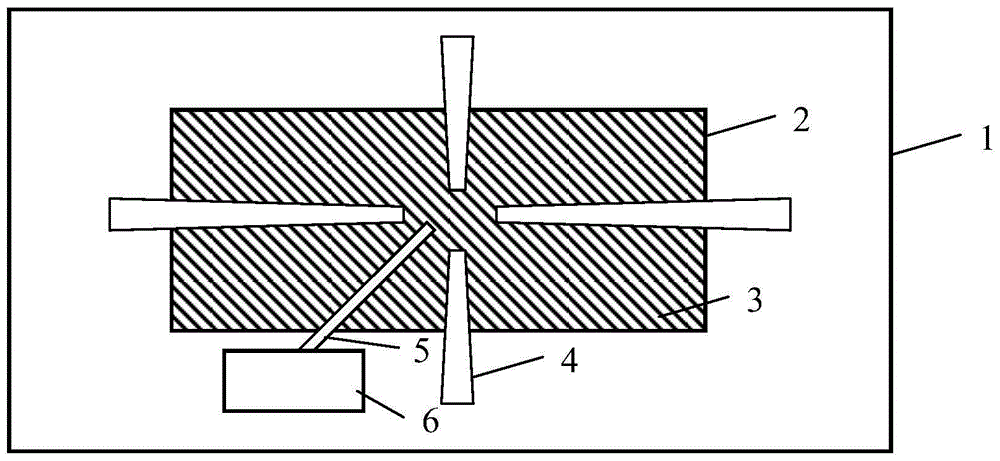

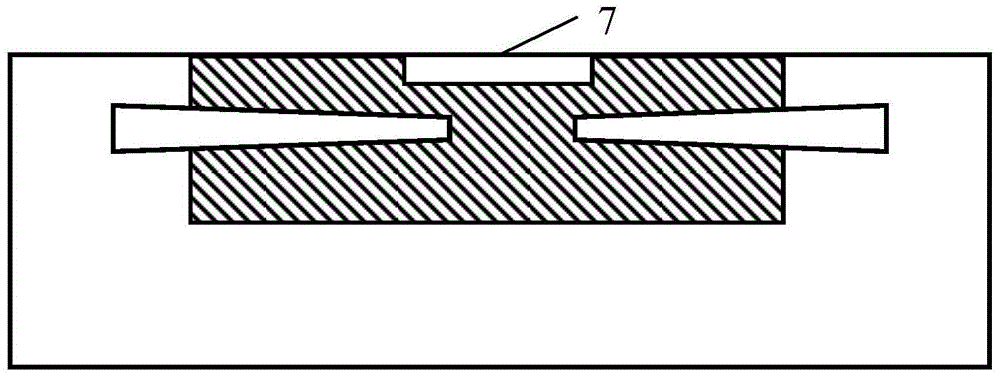

[0019] A laser engraving machine for processing wooden combs, characterized in that the laser engraving machine includes a workbench, and the workbench includes a base 1 that can move along the X-axis and Y-axis directions, and the base A rectangular processing tank 2 is arranged in the center, and the fixing agent 3 is filled in the processing tank, and the fixing agent can be softened under heating conditions. The four inner wall surfaces of the processing tank are provided with openings, and the four heating rods 4 are heated from the protruding from the opening on the inner wall of the processing tank, passing through the fixative and extending to the center of the processing tank, the heating rod includes a resistance wire and a sheath, and the thickness of the sheath gradually increases along the direction from the inner wall of the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com